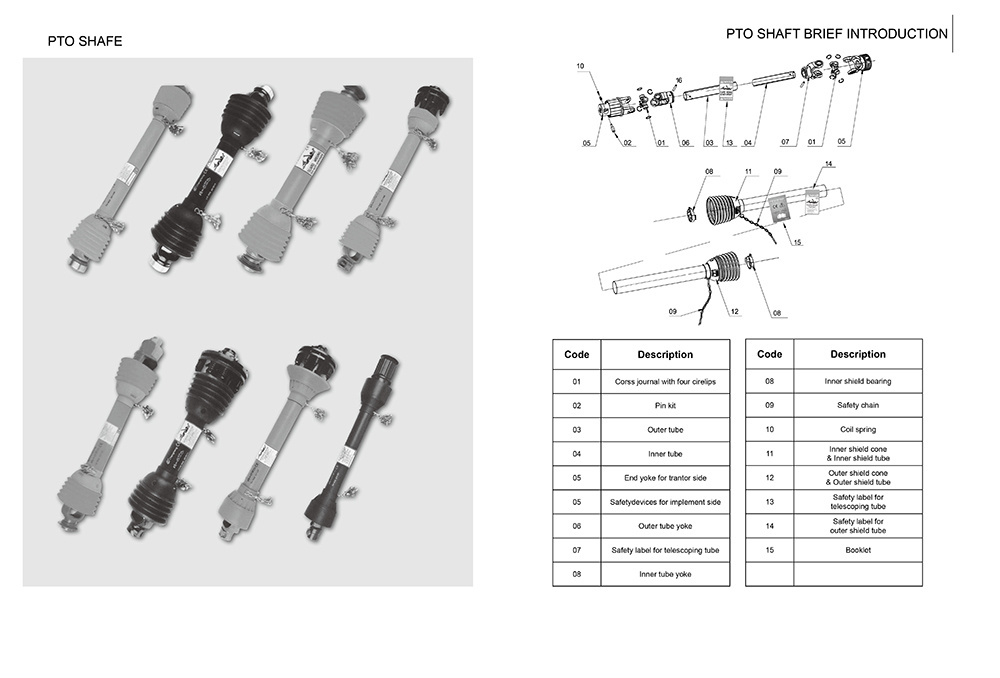

Forage Blower PTO Drive Shaft

Key words:

PTO shaft

Classification:

Product Details

Forage Blower PTO Drive Shaft

Minghua Gear made PTO drive shaft for a forage blower is critical in transferring power from a tractor to the blower itself. The forage blower requires significant power to operate, and the PTO shaft ensures that the power is efficiently transferred while also maintaining safety. Here are some considerations and details to keep in mind when selecting or working with a PTO drive shaft for a forage blower:

Key Considerations:

-

Horsepower (HP) Rating: Ensure that the PTO drive shaft matches the horsepower output of the tractor and the power needs of the forage blower. Most forage blowers will require a PTO shaft capable of handling power between 60 HP and 120 HP, though larger models may need more.

-

Length and Adjustability:

- The PTO shaft must be the correct length to connect the tractor to the forage blower. Adjustable or telescoping PTO shafts are common, as they allow the length to vary slightly depending on positioning.

-

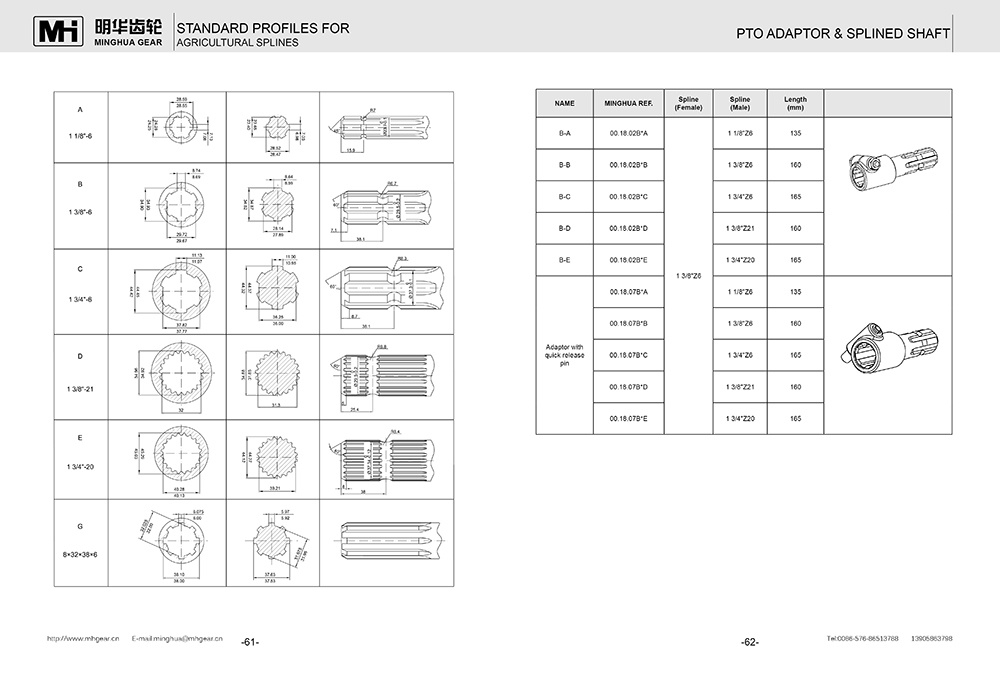

Connection Type (Shaft Spline)

- Tractor Side: Typically, tractors use a 6-spline or 21-spline connection.

- Forage Blower Side: Check the spline type and size of the forage blower input shaft to ensure compatibility.

-

Safety Features:

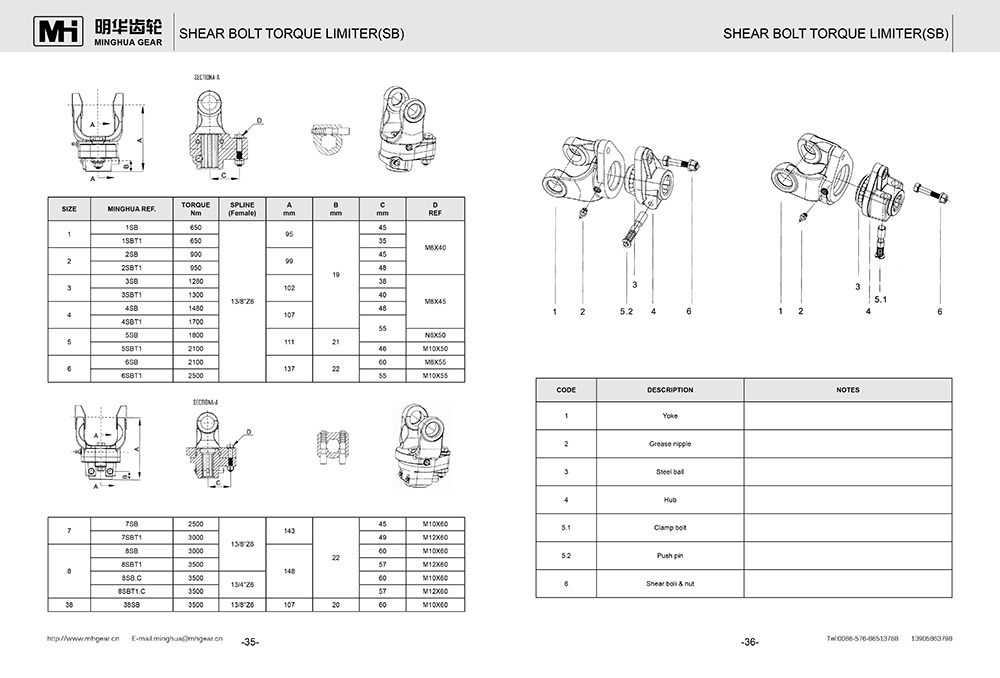

- Shear Pin or Slip Clutch: These protect the PTO drive shaft and the forage blower in case of an overload. A shear pin will break under extreme load, while a slip clutch disengages temporarily.

- Guarding: The PTO shaft should have protective guards around the rotating parts to prevent accidents.

-

Rotation Speed:

- Most forage blowers are designed for standard PTO rotation speeds (540 RPM or 1000 RPM). Ensure that your PTO shaft is rated for the correct speed.

-

Durability:

- PTO shafts used with forage blowers need to be heavy-duty to withstand high torque and operational stresses. Look for shafts made from high-strength steel with durable joints and bearings.

Maintenance Tips:

- Lubrication: Ensure that the PTO shaft is well-lubricated to prevent wear on the universal joints and telescoping tubes.

- Regular Inspection: Check for wear on the splines, joints, and guarding. Replace any damaged or worn parts before use.

- Balancing: An unbalanced PTO shaft can cause excessive vibration and wear. Make sure it is properly balanced during operation.

Applications

Would you like more details on selecting a specific model, or recommendations on brands and suppliers for forage blower PTO shafts?

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

PTO Shaft Description

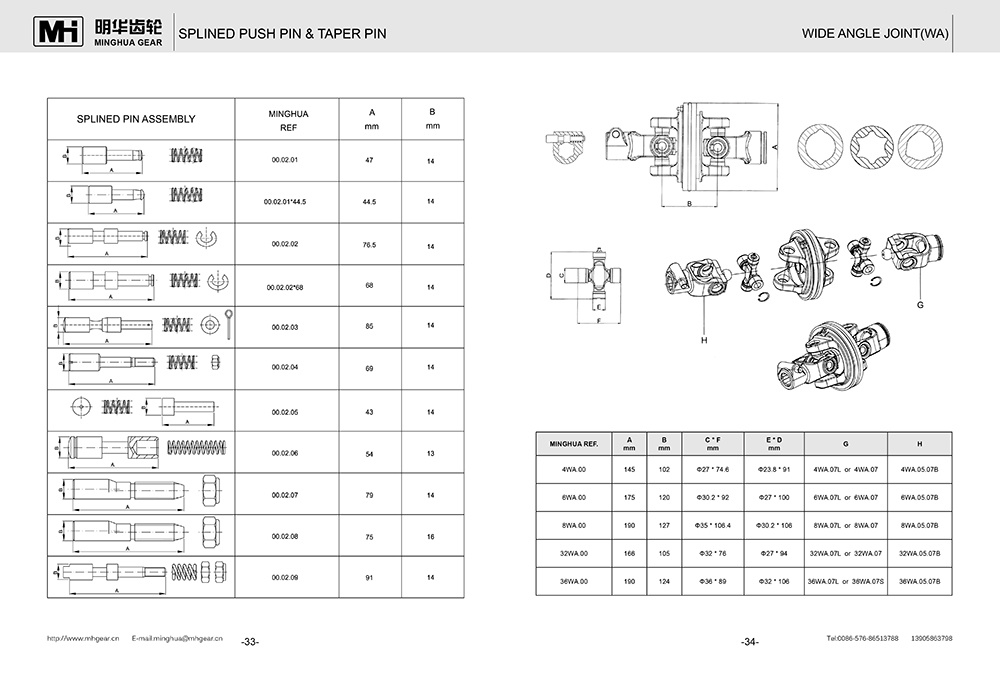

Yoke Type Double push pin,Bolt pins,Split pins,Push pin,Quick release,Ball attachment,Collar.....

Processing Of Yoke Forging

Plastic Cover YW;BW;YS;BS;Etc

Color Green;Orange;Yellow;Black Ect.

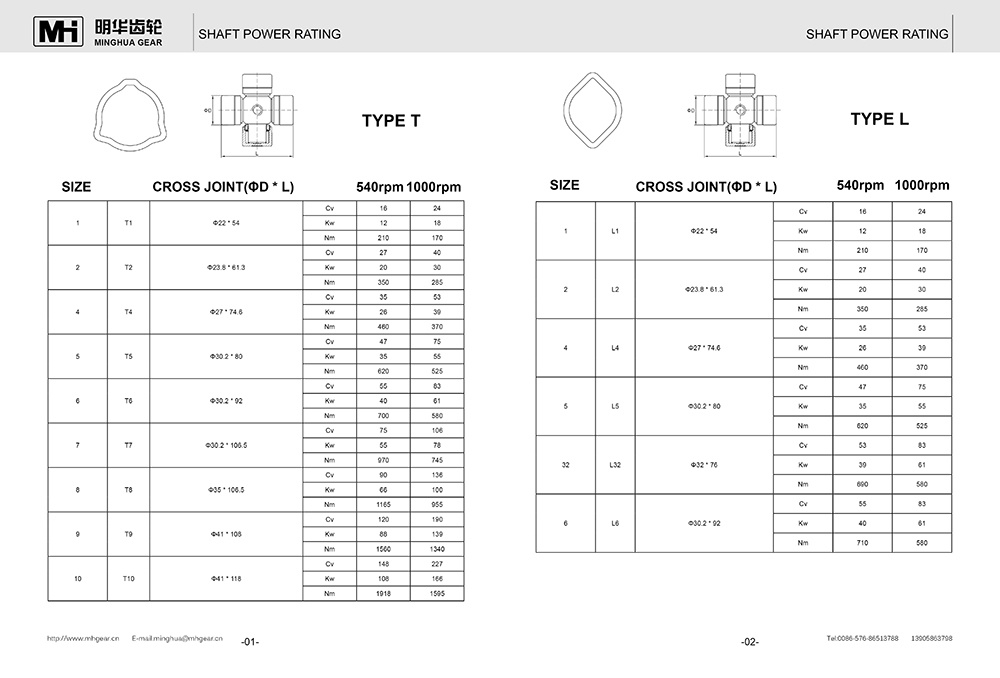

Series T1-T10; L1-L6;S6-S10;10HP-150HP with SA,RA,SB,SFF,WA,CV Etc

Tube Type Lemon,Trianglar,Star,Square,Hexangular,Spline,Special Ect

Processing Of Tube Cold drawn

Spline Type 1 1/8" Z6;1 3/8" Z6; 1 3/8" Z21 ;1 3/4" Z20; 1 3/4" Z6; 8-38*32*6 8-42*36*7; 8-48*42*8;

Place of Origin Wenling, China (Mainland)

Part description

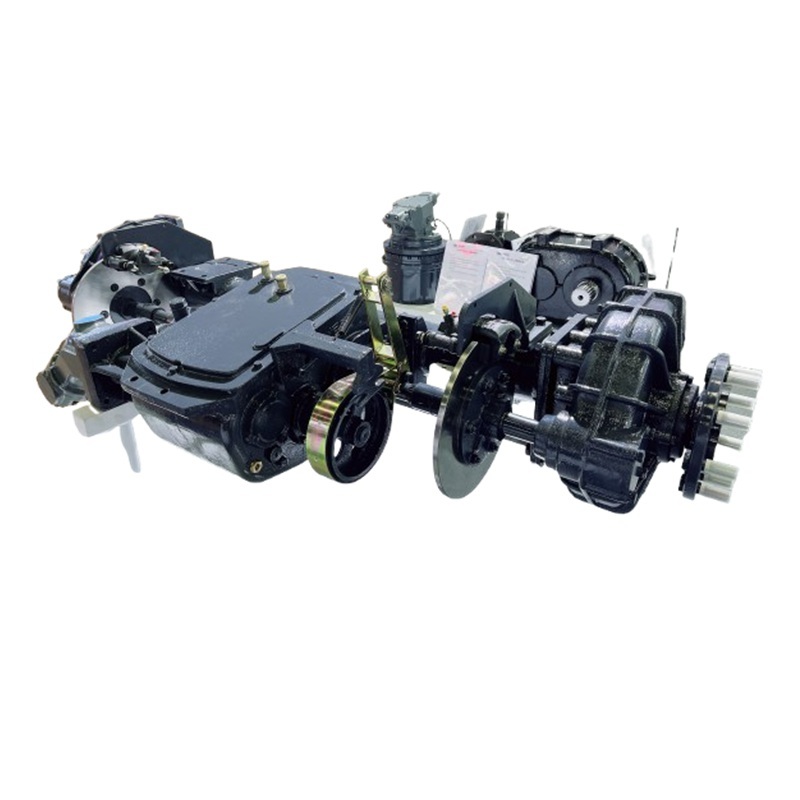

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Forage Blower PTO Drive Shaft

Key words:

PTO shaft

Classification:

Product Details

Forage Blower PTO Drive Shaft

Minghua Gear made PTO drive shaft for a forage blower is critical in transferring power from a tractor to the blower itself. The forage blower requires significant power to operate, and the PTO shaft ensures that the power is efficiently transferred while also maintaining safety. Here are some considerations and details to keep in mind when selecting or working with a PTO drive shaft for a forage blower:

Key Considerations:

-

Horsepower (HP) Rating: Ensure that the PTO drive shaft matches the horsepower output of the tractor and the power needs of the forage blower. Most forage blowers will require a PTO shaft capable of handling power between 60 HP and 120 HP, though larger models may need more.

-

Length and Adjustability:

- The PTO shaft must be the correct length to connect the tractor to the forage blower. Adjustable or telescoping PTO shafts are common, as they allow the length to vary slightly depending on positioning.

-

Connection Type (Shaft Spline)

- Tractor Side: Typically, tractors use a 6-spline or 21-spline connection.

- Forage Blower Side: Check the spline type and size of the forage blower input shaft to ensure compatibility.

-

Safety Features:

- Shear Pin or Slip Clutch: These protect the PTO drive shaft and the forage blower in case of an overload. A shear pin will break under extreme load, while a slip clutch disengages temporarily.

- Guarding: The PTO shaft should have protective guards around the rotating parts to prevent accidents.

-

Rotation Speed:

- Most forage blowers are designed for standard PTO rotation speeds (540 RPM or 1000 RPM). Ensure that your PTO shaft is rated for the correct speed.

-

Durability:

- PTO shafts used with forage blowers need to be heavy-duty to withstand high torque and operational stresses. Look for shafts made from high-strength steel with durable joints and bearings.

Maintenance Tips:

- Lubrication: Ensure that the PTO shaft is well-lubricated to prevent wear on the universal joints and telescoping tubes.

- Regular Inspection: Check for wear on the splines, joints, and guarding. Replace any damaged or worn parts before use.

- Balancing: An unbalanced PTO shaft can cause excessive vibration and wear. Make sure it is properly balanced during operation.

Applications

Would you like more details on selecting a specific model, or recommendations on brands and suppliers for forage blower PTO shafts?

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

PTO Shaft Description

Yoke Type Double push pin,Bolt pins,Split pins,Push pin,Quick release,Ball attachment,Collar.....

Processing Of Yoke Forging

Plastic Cover YW;BW;YS;BS;Etc

Color Green;Orange;Yellow;Black Ect.

Series T1-T10; L1-L6;S6-S10;10HP-150HP with SA,RA,SB,SFF,WA,CV Etc

Tube Type Lemon,Trianglar,Star,Square,Hexangular,Spline,Special Ect

Processing Of Tube Cold drawn

Spline Type 1 1/8" Z6;1 3/8" Z6; 1 3/8" Z21 ;1 3/4" Z20; 1 3/4" Z6; 8-38*32*6 8-42*36*7; 8-48*42*8;

Place of Origin Wenling, China (Mainland)

Part description

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.