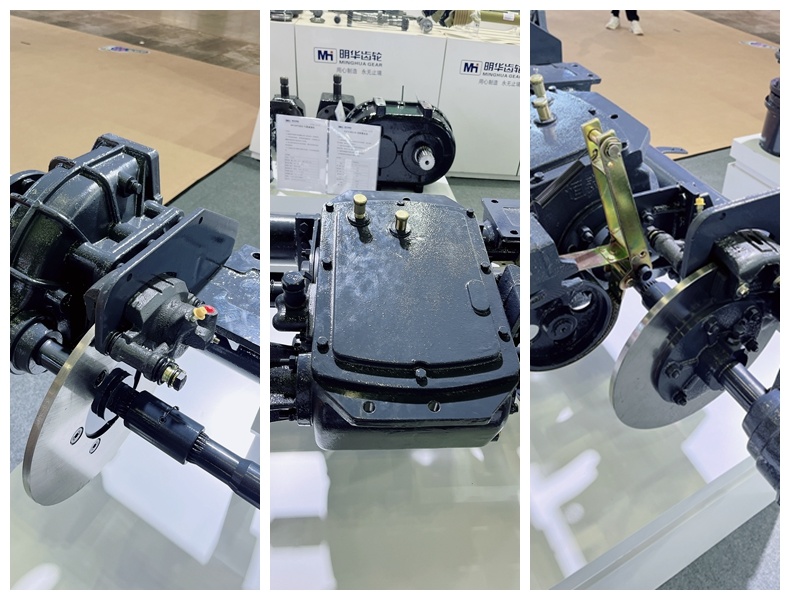

Rear Axle for Cotton Picker Harvester

Key words:

Drive gearbox axle

Classification:

Product Details

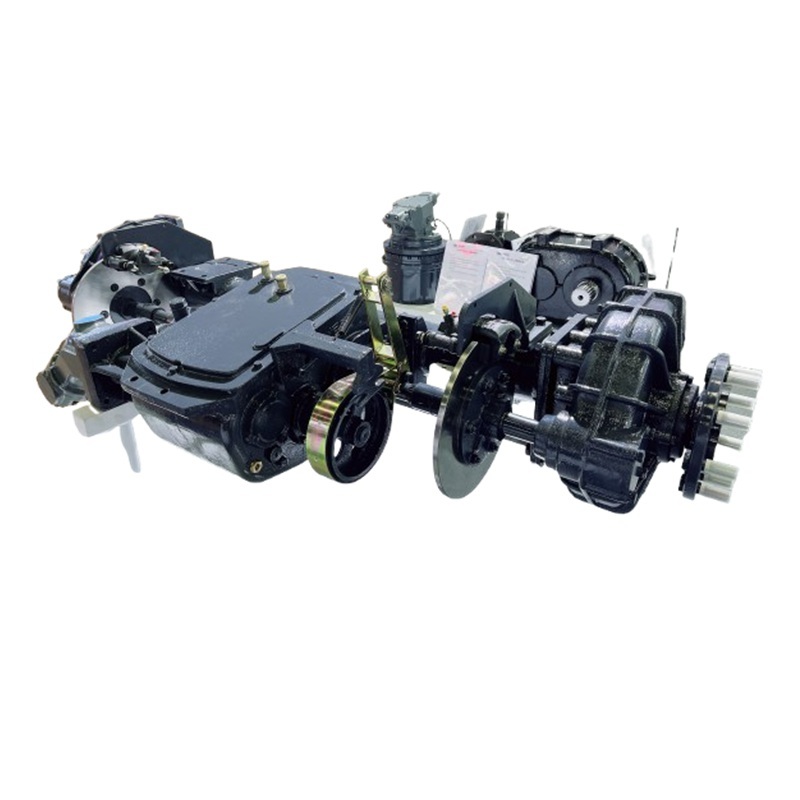

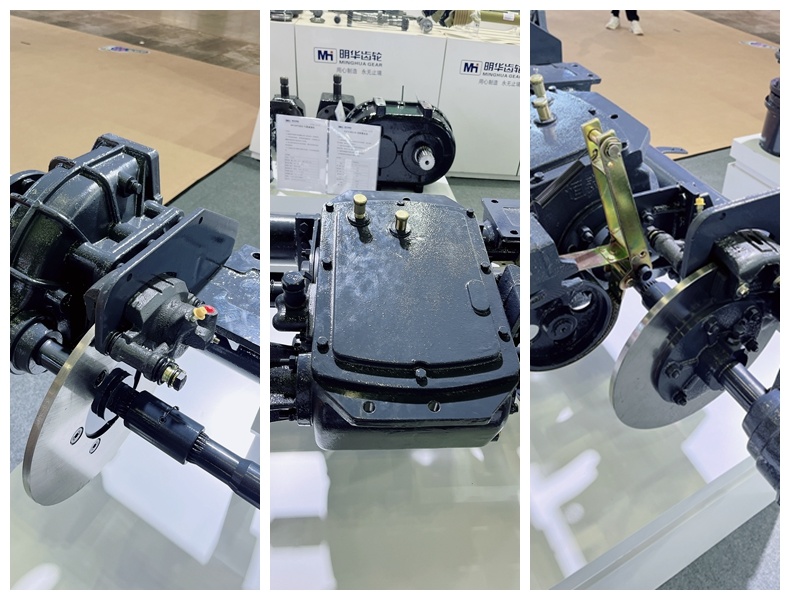

Rear Axle for Cotton pick up Harvester

A drive axle for a cotton pickup harvester is a critical component that transfers power from the gearbox to the wheels or tracks,

enabling efficient operation in field conditions. Given Minghua Gear’s expertise in manufacturing robust gearboxes for agricultural machinery, producing a drive axle for a cotton harvester could be a natural extension of your product range.

Here are key considerations for designing or sourcing such a component:

Technical Features

-

Durability

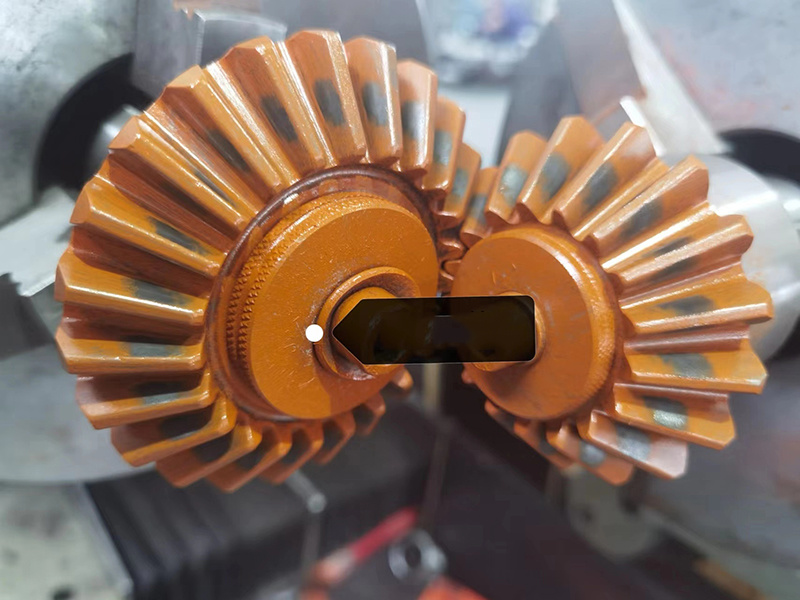

- Made of high-strength, heat-treated alloy steel to withstand heavy loads and vibrations.

- Corrosion-resistant coatings to handle outdoor exposure and agricultural chemicals.

-

Load Handling

- Designed for high torque and weight-bearing capacities, suitable for operating on uneven terrain.

- Optimized for the weight and load cycles typical in cotton harvesting operations.

-

Integration with Gearbox

- Seamless compatibility with your existing PTO or right-angle gearbox systems.

- Splined or flanged connections for secure power transfer.

-

Adjustability

- Adjustable width or modular designs to fit different harvester models.

- Provisions for dual or single-wheel setups.

-

Maintenance and Reliability

- Greaseable or sealed bearings to reduce maintenance frequency.

- Modular assemblies for easy replacement of worn-out parts.

|

Whole machine matching: The front axle can carry 8 tons, |

|||

|

Two speed ratio |

|||

|

Transmission speed ratio |

Low shift gear ratio |

High shift gear ratio |

|

|

|

12.842 |

4.404 |

|

|

Edge reduction ratio |

5.75 |

|

|

|

4 drive ratio |

0.30460074 |

|

|

|

Three speed ratio |

|||

|

Transmission speed ratio |

Shift 1 gear ratio |

Shift 2 gear ratio |

Shift 3 gear ratio |

|

|

22.644 |

9.403 |

3.747 |

|

Edge reduction ratio |

5.75 |

|

|

|

4 drive ratio |

0.30460074 |

|

|

Applications:

- Designed for use in modern corn harvesters, helping improve field performance and operational reliability.

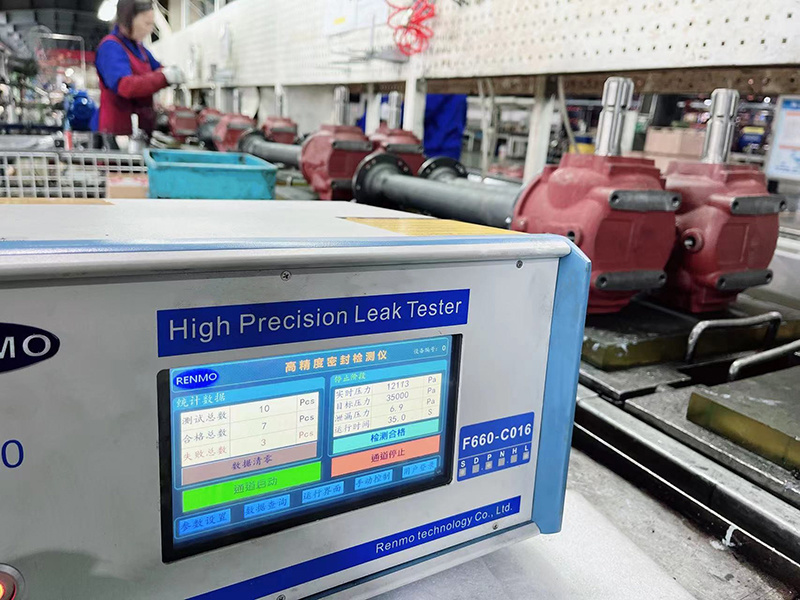

Testing Equipment

Full process inspection and testing.

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

Rear Axle for Cotton Picker Harvester

Key words:

Drive gearbox axle

Classification:

Product Details

Rear Axle for Cotton pick up Harvester

A drive axle for a cotton pickup harvester is a critical component that transfers power from the gearbox to the wheels or tracks,

enabling efficient operation in field conditions. Given Minghua Gear’s expertise in manufacturing robust gearboxes for agricultural machinery, producing a drive axle for a cotton harvester could be a natural extension of your product range.

Here are key considerations for designing or sourcing such a component:

Technical Features

-

Durability

- Made of high-strength, heat-treated alloy steel to withstand heavy loads and vibrations.

- Corrosion-resistant coatings to handle outdoor exposure and agricultural chemicals.

-

Load Handling

- Designed for high torque and weight-bearing capacities, suitable for operating on uneven terrain.

- Optimized for the weight and load cycles typical in cotton harvesting operations.

-

Integration with Gearbox

- Seamless compatibility with your existing PTO or right-angle gearbox systems.

- Splined or flanged connections for secure power transfer.

-

Adjustability

- Adjustable width or modular designs to fit different harvester models.

- Provisions for dual or single-wheel setups.

-

Maintenance and Reliability

- Greaseable or sealed bearings to reduce maintenance frequency.

- Modular assemblies for easy replacement of worn-out parts.

|

Whole machine matching: The front axle can carry 8 tons, |

|||

|

Two speed ratio |

|||

|

Transmission speed ratio |

Low shift gear ratio |

High shift gear ratio |

|

|

|

12.842 |

4.404 |

|

|

Edge reduction ratio |

5.75 |

|

|

|

4 drive ratio |

0.30460074 |

|

|

|

Three speed ratio |

|||

|

Transmission speed ratio |

Shift 1 gear ratio |

Shift 2 gear ratio |

Shift 3 gear ratio |

|

|

22.644 |

9.403 |

3.747 |

|

Edge reduction ratio |

5.75 |

|

|

|

4 drive ratio |

0.30460074 |

|

|

Applications:

- Designed for use in modern corn harvesters, helping improve field performance and operational reliability.

Testing Equipment

Full process inspection and testing.

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.