FAQ

Frequently Asked Question

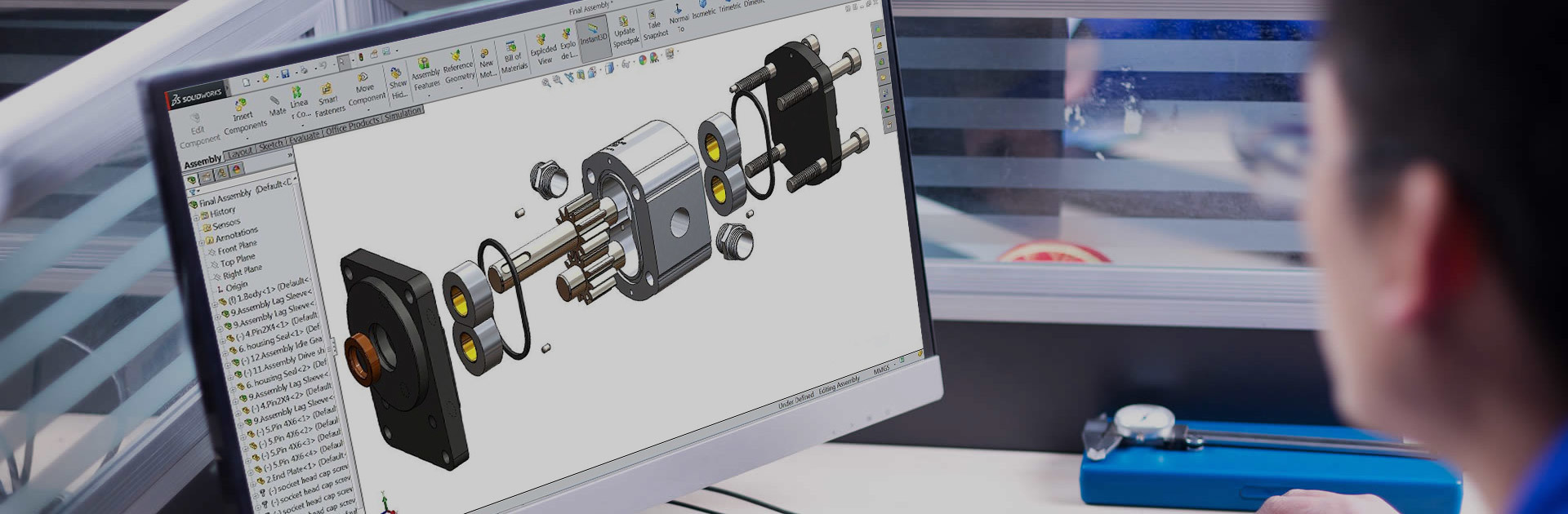

Hydraulic gear oil pump trapped oil noise and noise reduction strategy

First, the reason for the noise:

Gear oil pump at work, a portion of the hydraulic oil is trapped in the two pairs of gear meshing formed and suction and pressure oil chamber are not connected to the closed volume. When its capacity from large to small, the trapped hydraulic oil is squeezed, the pressure rate rises, much higher than the output pressure of the gear oil pump (trapped liquid from the leakage gap can be forced out), so that the shaft and bearings are subjected to a considerable shock load, causing vibration and noise; and when the trapped oil volume from small to large, the formation of a local vacuum, so that the oil dissolved in the gas can be separated, resulting in the "air pockets". "Cavitation" phenomenon, bringing cavitation, vibration and noise.

Second, noise reduction strategies.

1, external meshing hydraulic gear oil pump is mainly in the sleeve (or inverted plate) and other internal parts on the open "unloading slot". Slotting principle is to ensure that the gear oil pump internal high and low pressure chamber does not communicate with each other under the premise of trying to make the trapped oil volume and high-pressure chamber or low-pressure chamber, in order to achieve part of the removal of trapped oil phenomenon, thereby reducing noise and vibration.

Copyright©2023 Wenling Minghua Gear Co., Ltd.