PTO Drive Gearbox for Finishing Mower

Key words:

Gearboxes

Classification:

Product Details

PTO Drive Gearbox for Finishing Mower

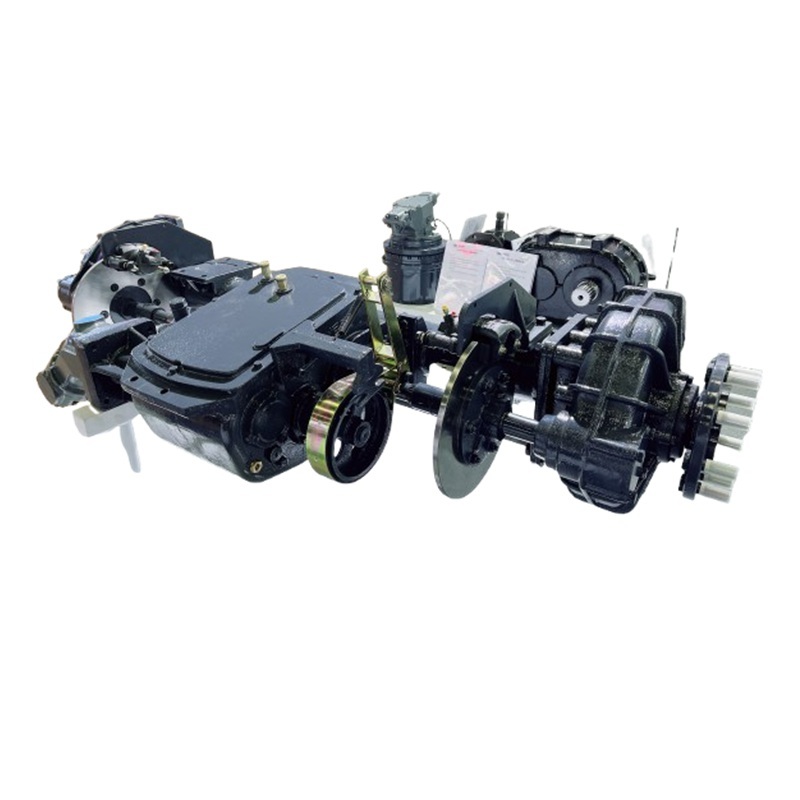

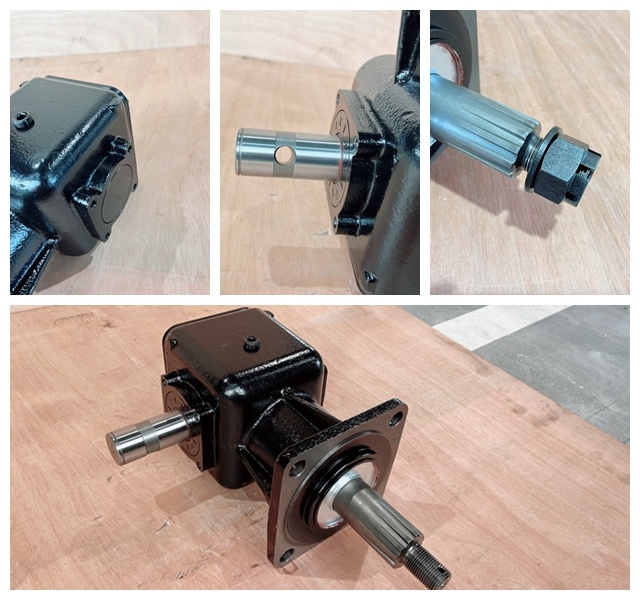

Minghua Gear's production of PTO drive gearboxes for finish mowers adds a versatile component to their product line. These gearboxes, designed for efficient power transfer from a tractor’s PTO to the mower blades, are likely built to handle the varied demands of finish mowing, such as precise cutting and durability in agricultural and landscaping environments.

Key Features of a PTO Drive Gearbox for a Finishing Mower:

-

Power Transfer Efficiency:

- The gearbox converts the rotational power from the PTO shaft to the mower blades, maintaining optimal blade speed for precise grass cutting.

-

Gear Ratio:

- The gear ratio is crucial for determining blade speed and efficiency. A typical gearbox for finishing mowers may have a gear ratio like 1:1 or 1:1.5, ensuring the blades rotate at the ideal speed for a clean, even cut.

-

Durability:

- Gearboxes are usually built with cast iron or aluminum housings, making them durable and able to withstand the rigors of mowing in challenging conditions.

-

PTO Compatibility:

- These gearboxes are designed to work with standard PTO speeds, typically 540 RPM or 1000 RPM, making them compatible with a wide range of tractors.

-

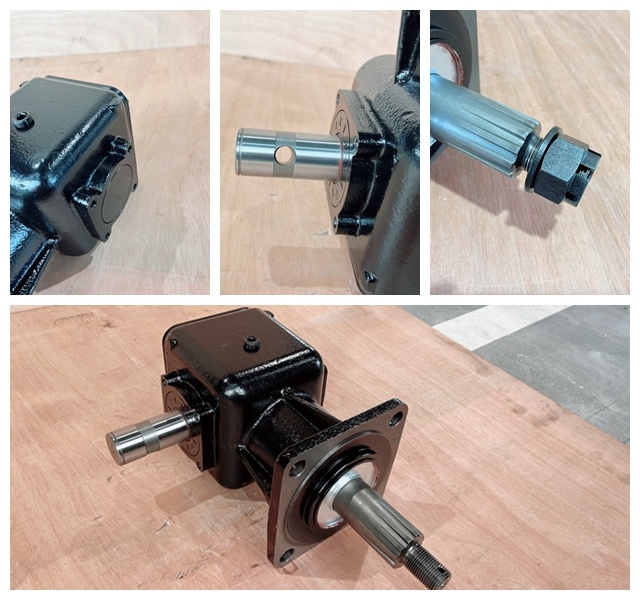

Input and Output Shafts:

- Gearboxes feature a splined input shaft to connect to the tractor’s PTO and an output shaft connected to the mower blades.

-

Sealing and Lubrication:

- Proper seals and lubrication systems ensure that the gearbox operates smoothly and minimizes the need for frequent maintenance.

-

Mounting Configuration:

- These gearboxes are usually designed with flanges and bolt holes for easy mounting to the mower deck, ensuring stability during operation.

Benefits of Using PTO Gearboxes in Finishing Mowers:

- Consistent Cutting Quality: Properly powered blades maintain consistent cutting performance, leaving a clean, professional finish.

- Durable Under Tough Conditions: High-quality materials and designs withstand wear, extending the life of the gearbox and mower.

- Low Maintenance: Advanced sealing and lubrication reduce the need for frequent service.

In a finishing mower, which requires precision cutting for lawns, parks, and sports fields, the PTO gearbox plays a crucial role in ensuring the mower operates efficiently and produces a smooth, even finish.

Applications

Finishing mower gearbox

- PTO gearbox for finishing mowers

- Gearbox for finishing mower attachments

- Agricultural gearboxes for finishing mowers

- Durable finishing mower PTO gearbox

- High-performance gearbox for finish mowers

- Rotary mower gearbox

- Replacement gearbox for finishing mowers

The PTO drive gearbox for a finishing mower is sometimes referred to by different names depending on the industry or region. Some alternative names include:

- Mower Gearbox

- Finishing Mower Gearbox

- PTO Mower Gearbox

- PTO Transmission Gearbox

- Mower Deck Gearbox

- Rotary Mower Gearbox

- PTO Reduction Gearbox

All of these terms generally refer to the same component, which is responsible for transferring power from a tractor's PTO to the blades of a finishing mower.

Packaging

Plastic sleeve covered on shaft.

Thick foam plate separate avoid collide.

Thick foam bag cover whole export plywood crate box.

Strength packing belt covered the crate box.

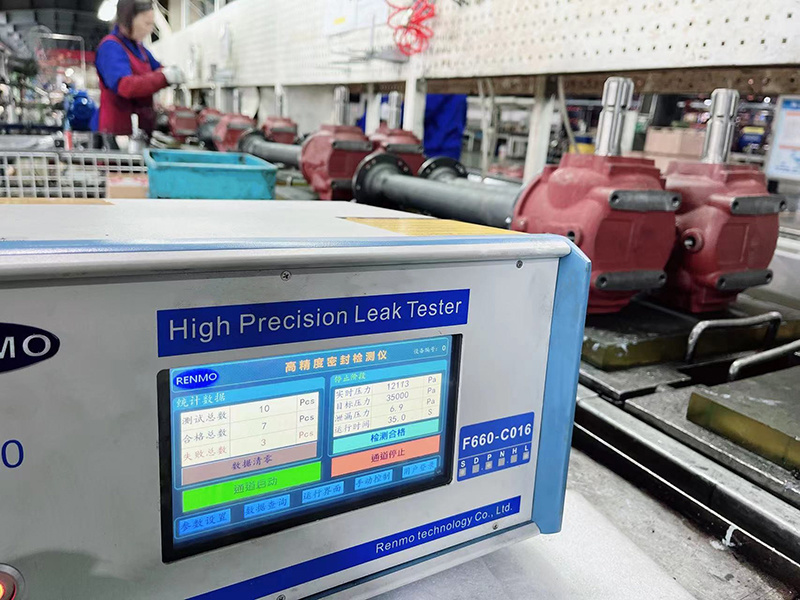

Testing Equipment

Full process inspection and testing.

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

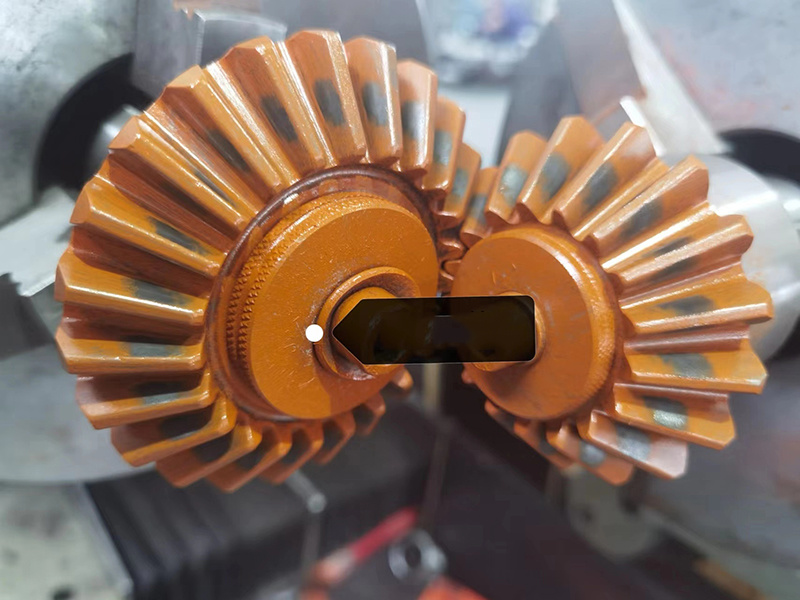

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

PTO Drive Gearbox for Finishing Mower

Key words:

Gearboxes

Classification:

Product Details

PTO Drive Gearbox for Finishing Mower

Minghua Gear's production of PTO drive gearboxes for finish mowers adds a versatile component to their product line. These gearboxes, designed for efficient power transfer from a tractor’s PTO to the mower blades, are likely built to handle the varied demands of finish mowing, such as precise cutting and durability in agricultural and landscaping environments.

Key Features of a PTO Drive Gearbox for a Finishing Mower:

-

Power Transfer Efficiency:

- The gearbox converts the rotational power from the PTO shaft to the mower blades, maintaining optimal blade speed for precise grass cutting.

-

Gear Ratio:

- The gear ratio is crucial for determining blade speed and efficiency. A typical gearbox for finishing mowers may have a gear ratio like 1:1 or 1:1.5, ensuring the blades rotate at the ideal speed for a clean, even cut.

-

Durability:

- Gearboxes are usually built with cast iron or aluminum housings, making them durable and able to withstand the rigors of mowing in challenging conditions.

-

PTO Compatibility:

- These gearboxes are designed to work with standard PTO speeds, typically 540 RPM or 1000 RPM, making them compatible with a wide range of tractors.

-

Input and Output Shafts:

- Gearboxes feature a splined input shaft to connect to the tractor’s PTO and an output shaft connected to the mower blades.

-

Sealing and Lubrication:

- Proper seals and lubrication systems ensure that the gearbox operates smoothly and minimizes the need for frequent maintenance.

-

Mounting Configuration:

- These gearboxes are usually designed with flanges and bolt holes for easy mounting to the mower deck, ensuring stability during operation.

Benefits of Using PTO Gearboxes in Finishing Mowers:

- Consistent Cutting Quality: Properly powered blades maintain consistent cutting performance, leaving a clean, professional finish.

- Durable Under Tough Conditions: High-quality materials and designs withstand wear, extending the life of the gearbox and mower.

- Low Maintenance: Advanced sealing and lubrication reduce the need for frequent service.

In a finishing mower, which requires precision cutting for lawns, parks, and sports fields, the PTO gearbox plays a crucial role in ensuring the mower operates efficiently and produces a smooth, even finish.

Applications

Finishing mower gearbox

- PTO gearbox for finishing mowers

- Gearbox for finishing mower attachments

- Agricultural gearboxes for finishing mowers

- Durable finishing mower PTO gearbox

- High-performance gearbox for finish mowers

- Rotary mower gearbox

- Replacement gearbox for finishing mowers

The PTO drive gearbox for a finishing mower is sometimes referred to by different names depending on the industry or region. Some alternative names include:

- Mower Gearbox

- Finishing Mower Gearbox

- PTO Mower Gearbox

- PTO Transmission Gearbox

- Mower Deck Gearbox

- Rotary Mower Gearbox

- PTO Reduction Gearbox

All of these terms generally refer to the same component, which is responsible for transferring power from a tractor's PTO to the blades of a finishing mower.

Packaging

Plastic sleeve covered on shaft.

Thick foam plate separate avoid collide.

Thick foam bag cover whole export plywood crate box.

Strength packing belt covered the crate box.

Testing Equipment

Full process inspection and testing.

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.