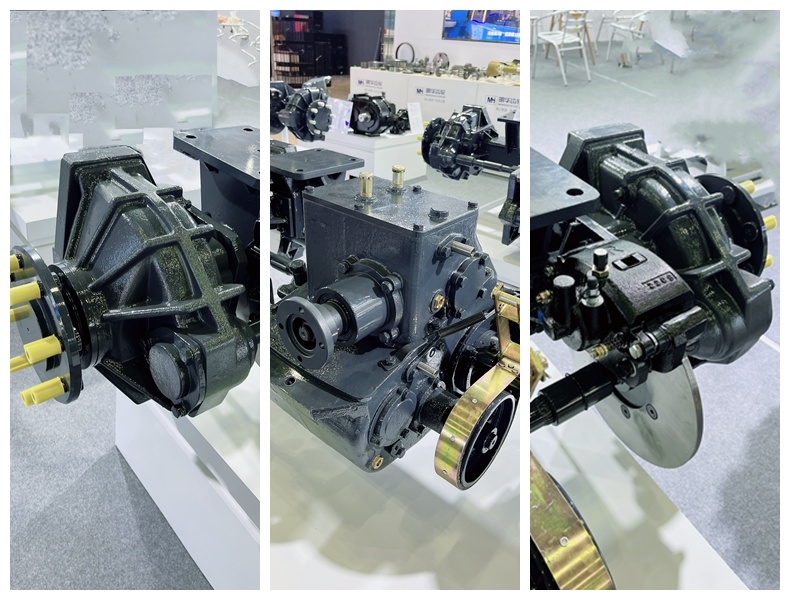

Rear Axle for Combine Harvester

Key words:

Drive gearbox axle

Classification:

Product Details

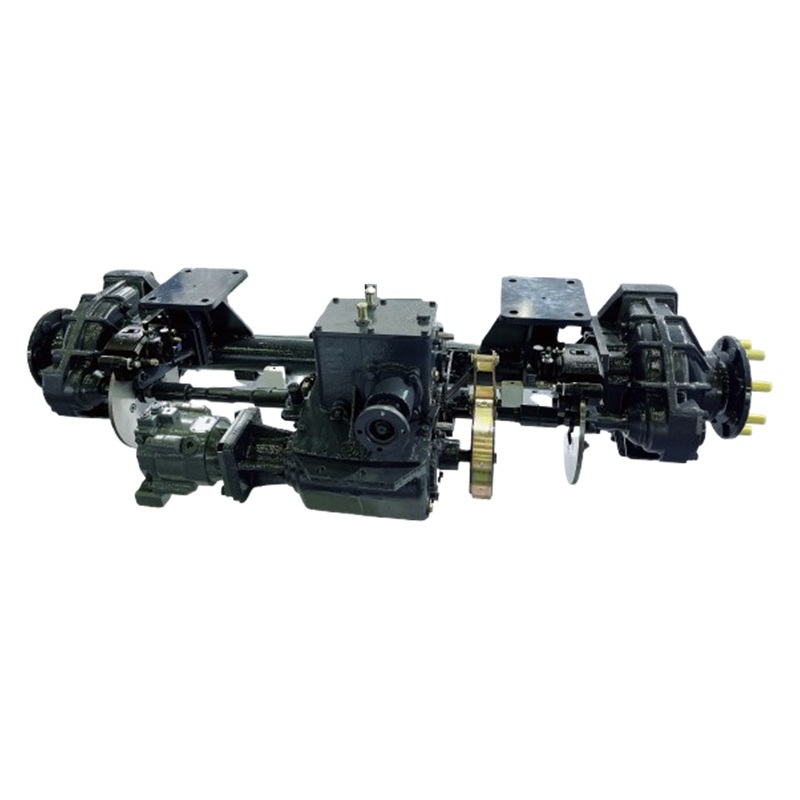

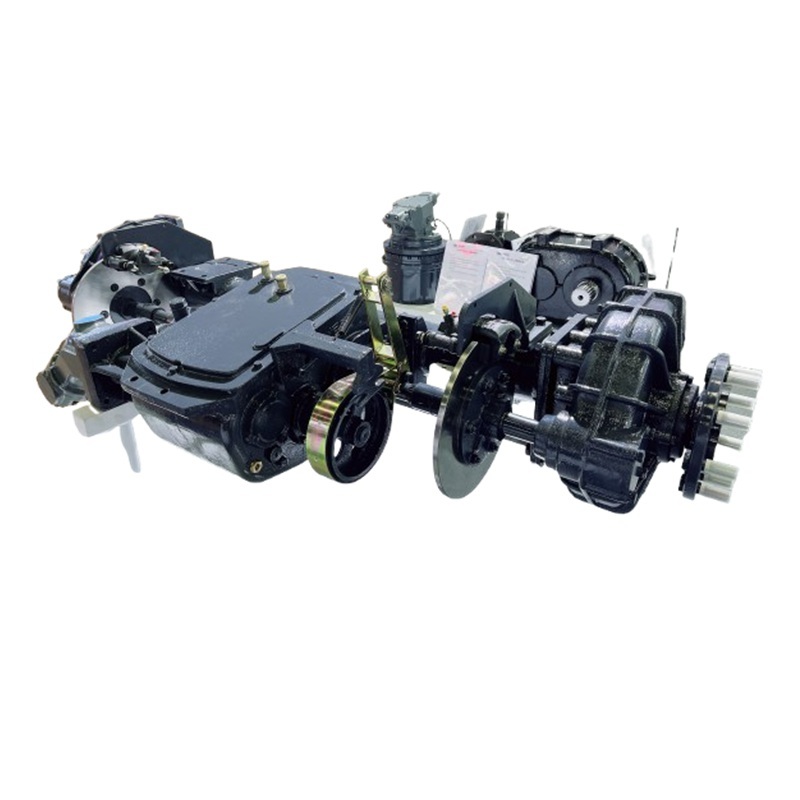

Rear Axle for Combine Harvester

The MHS7.0SXJ Drive Axle for Corn Harvesters is likely designed to meet the specific demands of agricultural machinery. Such drive axles are built to withstand heavy loads, rugged field conditions, and ensure efficient transfer of power to the harvester’s wheels or tracks.

Key Features (Typical for this category):

- High Load Capacity: Capable of handling the weight of a fully loaded corn harvester.

- Durable Materials: Constructed from high-strength steel or alloys to endure challenging agricultural environments.

- Optimized Gear Ratios: Ensures efficient power delivery for various field conditions.

- Hydraulic Integration: Often includes provisions for hydraulic systems to support steering or differential locking.

- Maintenance-Friendly Design: Features like sealed bearings and easily accessible service points to minimize downtime.

|

Whole machine matching: The front axle can carry 7 tons, and the whole machine can carry 10 tons |

|||

|

Two speed ratio |

|||

|

Transmission speed ratio |

Low shift gear ratio |

High shift gear ratio |

|

|

|

10.563 |

4.404 |

|

|

Edge reduction ratio |

6.09 |

|

|

|

4 drive ratio |

0.30460074 |

|

|

|

Three speed ratio |

|||

|

Transmission speed ratio |

Shift 1 gear ratio |

Shift 2 gear ratio |

Shift 3 gear ratio |

|

|

22.644 |

8.549 |

3.169 |

|

Edge reduction ratio |

6.09 |

|

|

|

4 drive ratio |

0.30460074 |

|

|

Applications:

- Designed for use in modern corn harvesters, helping improve field performance and operational reliability.

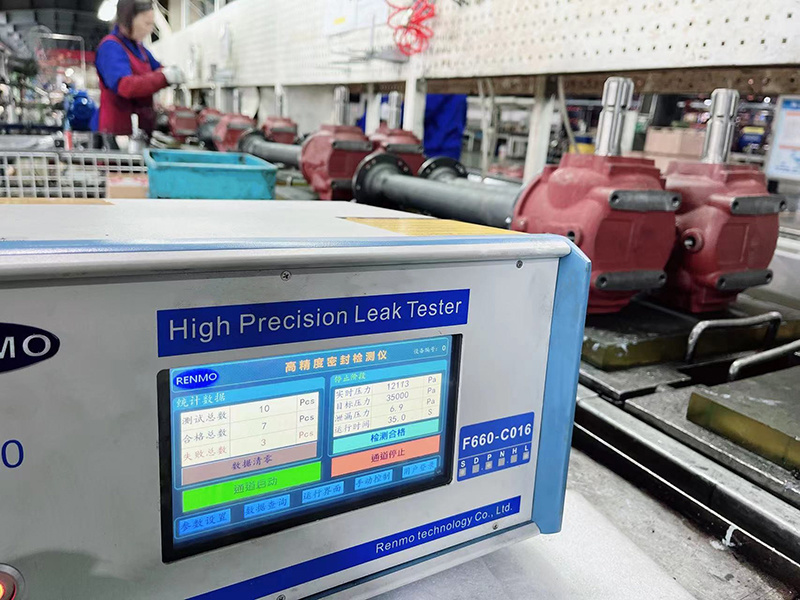

Testing Equipment

Full process inspection and testing.

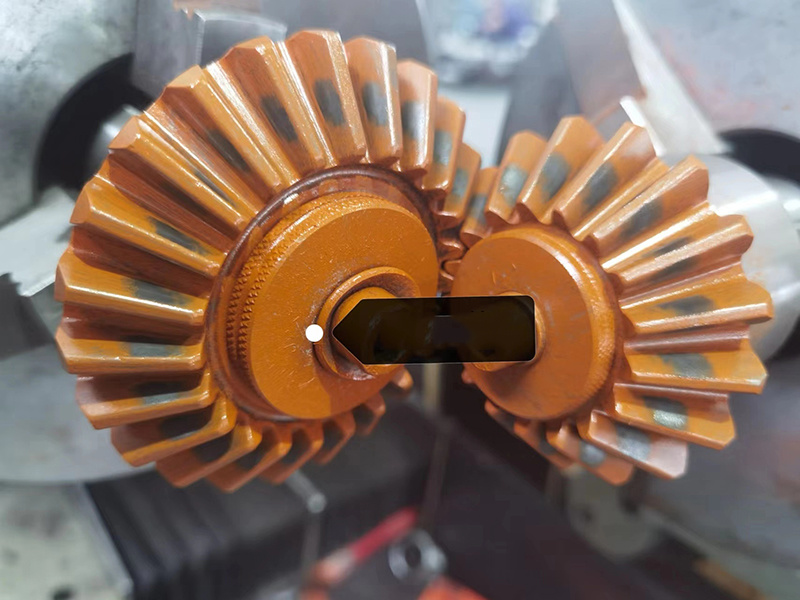

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

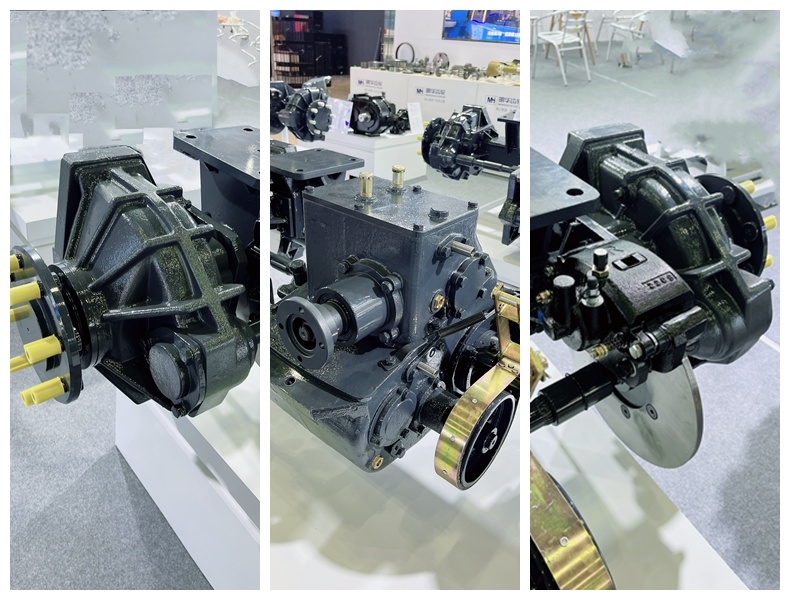

Rear Axle for Combine Harvester

Key words:

Drive gearbox axle

Classification:

Product Details

Rear Axle for Combine Harvester

The MHS7.0SXJ Drive Axle for Corn Harvesters is likely designed to meet the specific demands of agricultural machinery. Such drive axles are built to withstand heavy loads, rugged field conditions, and ensure efficient transfer of power to the harvester’s wheels or tracks.

Key Features (Typical for this category):

- High Load Capacity: Capable of handling the weight of a fully loaded corn harvester.

- Durable Materials: Constructed from high-strength steel or alloys to endure challenging agricultural environments.

- Optimized Gear Ratios: Ensures efficient power delivery for various field conditions.

- Hydraulic Integration: Often includes provisions for hydraulic systems to support steering or differential locking.

- Maintenance-Friendly Design: Features like sealed bearings and easily accessible service points to minimize downtime.

|

Whole machine matching: The front axle can carry 7 tons, and the whole machine can carry 10 tons |

|||

|

Two speed ratio |

|||

|

Transmission speed ratio |

Low shift gear ratio |

High shift gear ratio |

|

|

|

10.563 |

4.404 |

|

|

Edge reduction ratio |

6.09 |

|

|

|

4 drive ratio |

0.30460074 |

|

|

|

Three speed ratio |

|||

|

Transmission speed ratio |

Shift 1 gear ratio |

Shift 2 gear ratio |

Shift 3 gear ratio |

|

|

22.644 |

8.549 |

3.169 |

|

Edge reduction ratio |

6.09 |

|

|

|

4 drive ratio |

0.30460074 |

|

|

Applications:

- Designed for use in modern corn harvesters, helping improve field performance and operational reliability.

Testing Equipment

Full process inspection and testing.

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.