Drive Head Gearbox for Post Hole Digger

Key words:

Gearboxes

Classification:

Product Details

Drive Head Gearbox for Post Hole Digger

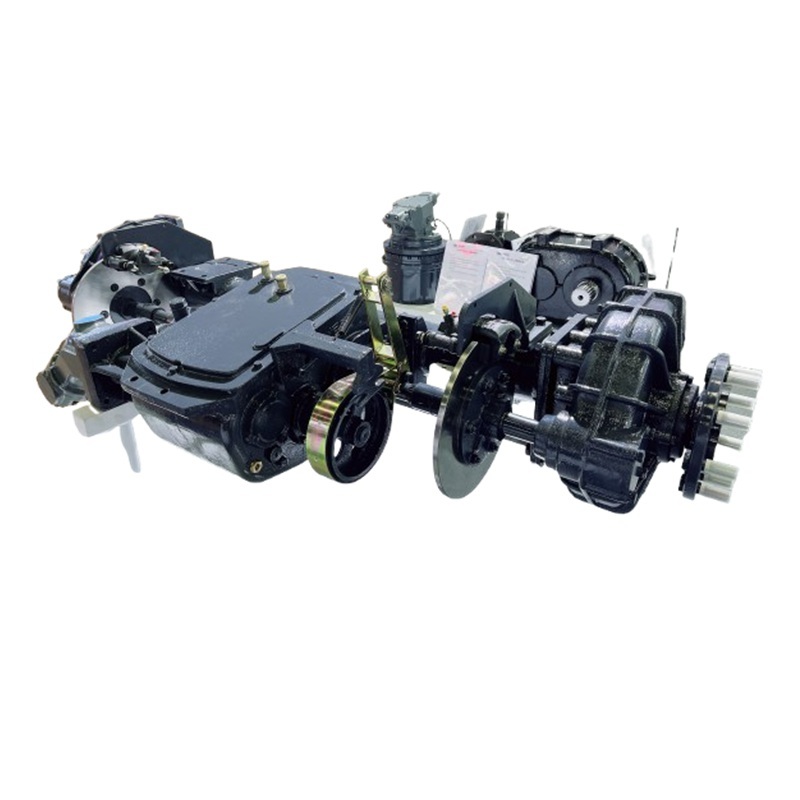

A Drive Head Gearbox for a Post Hole Digger is a crucial component that transmits power from a tractor's PTO (Power Take-Off) to the auger, allowing it to dig efficiently. Here’s a breakdown of the key characteristics and features of such a gearbox:

Key Features of a Drive Head Gearbox for a Post Hole Digger:

-

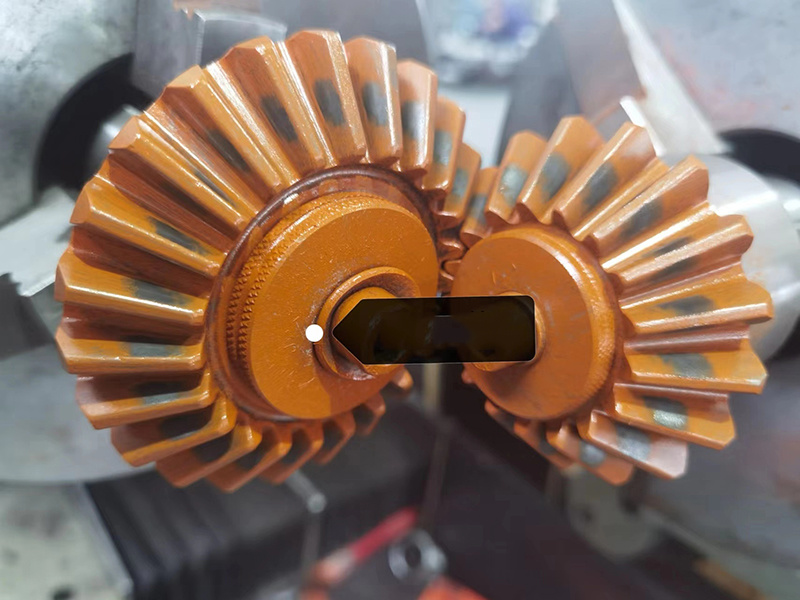

High Torque Output:

- The gearbox is designed to convert the high-speed, low-torque input from the PTO into low-speed, high-torque output, ideal for digging through soil, clay, or rock.

-

Gear Ratio:

- Gear ratios commonly used in post hole diggers are around 3:1 or 4:1, which reduces the input speed while increasing the output torque to power the auger effectively.

-

Heavy-Duty Construction:

- The housing is typically made from cast iron or steel, ensuring it can withstand the stress of digging in tough soil conditions.

- The internal gears are usually made of hardened steel for durability and to resist wear over time.

-

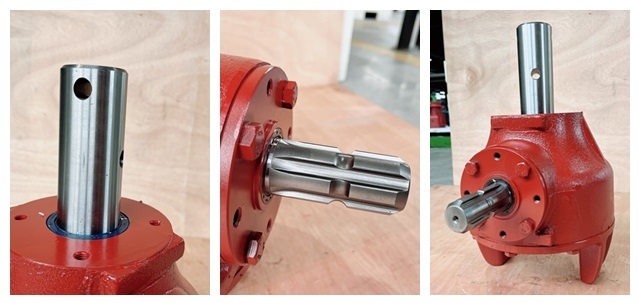

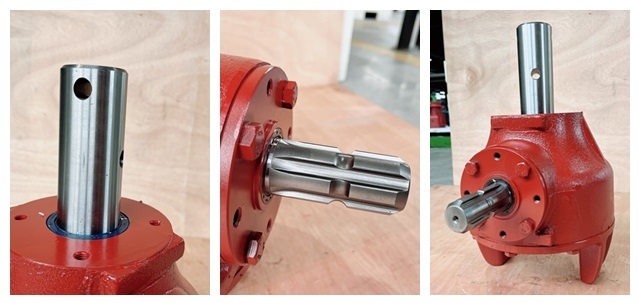

Input Shaft:

- The input shaft connects directly to the PTO shaft of the tractor, usually rated for standard PTO speeds of 540 RPM.

- Some models may also support 1000 RPM PTO shafts, depending on the size and type of post hole digger.

-

Output Shaft:

- The output shaft connects to the auger and is responsible for transmitting rotational force. It typically features a standardized size to match various augers.

- The output shaft is often reinforced to handle the heavy torque required for breaking ground.

-

Mounting Configuration:

- Most drive head gearboxes are equipped with standard mounting flanges and can be easily fitted onto a wide range of post hole digger frames.

- Some designs are built with quick-attach systems for easy swapping of gearboxes or augers.

-

Lubrication and Sealing:

- Gearboxes often have oil bath lubrication to keep internal gears running smoothly.

- High-quality seals protect against dust, dirt, and moisture to prevent internal damage during operation.

-

Keywords:

Post hole digger gearbox-

- PTO gearbox for post hole diggers

- Gearbox for auger attachments

- Agricultural gearboxes for post hole diggers

- Durable post hole digger gearbox

- High-performance auger gearbox

- Post hole digger PTO drive gearbox

- Heavy-duty gearbox for auger machines

-

Applications:

- - Agricultural PTO gearbox for auger drilling

- - Gearboxes for soil drilling equipment

-

- Auger drive gearboxes for post hole diggers

- Precision gearbox for earth augers

- Drivetrain solutions for post hole diggers

- Compact and efficient gearboxes for augers

- Maintenance-free gearboxes for drilling equipment

Minghua Gear or similar manufacturers might offer gearboxes that match these specifications for post hole diggers. Would you like to explore specific models or technical details for your project?

Packaging

Plastic sleeve covered on shaft.

Thick foam plate separate avoid collide.

Thick foam bag cover whole export plywood crate box.

Strength packing belt covered the crate box.

Testing Equipment

Full process inspection and testing.

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Drive Head Gearbox for Post Hole Digger

Key words:

Gearboxes

Classification:

Product Details

Drive Head Gearbox for Post Hole Digger

A Drive Head Gearbox for a Post Hole Digger is a crucial component that transmits power from a tractor's PTO (Power Take-Off) to the auger, allowing it to dig efficiently. Here’s a breakdown of the key characteristics and features of such a gearbox:

Key Features of a Drive Head Gearbox for a Post Hole Digger:

-

High Torque Output:

- The gearbox is designed to convert the high-speed, low-torque input from the PTO into low-speed, high-torque output, ideal for digging through soil, clay, or rock.

-

Gear Ratio:

- Gear ratios commonly used in post hole diggers are around 3:1 or 4:1, which reduces the input speed while increasing the output torque to power the auger effectively.

-

Heavy-Duty Construction:

- The housing is typically made from cast iron or steel, ensuring it can withstand the stress of digging in tough soil conditions.

- The internal gears are usually made of hardened steel for durability and to resist wear over time.

-

Input Shaft:

- The input shaft connects directly to the PTO shaft of the tractor, usually rated for standard PTO speeds of 540 RPM.

- Some models may also support 1000 RPM PTO shafts, depending on the size and type of post hole digger.

-

Output Shaft:

- The output shaft connects to the auger and is responsible for transmitting rotational force. It typically features a standardized size to match various augers.

- The output shaft is often reinforced to handle the heavy torque required for breaking ground.

-

Mounting Configuration:

- Most drive head gearboxes are equipped with standard mounting flanges and can be easily fitted onto a wide range of post hole digger frames.

- Some designs are built with quick-attach systems for easy swapping of gearboxes or augers.

-

Lubrication and Sealing:

- Gearboxes often have oil bath lubrication to keep internal gears running smoothly.

- High-quality seals protect against dust, dirt, and moisture to prevent internal damage during operation.

-

Keywords:

Post hole digger gearbox-

- PTO gearbox for post hole diggers

- Gearbox for auger attachments

- Agricultural gearboxes for post hole diggers

- Durable post hole digger gearbox

- High-performance auger gearbox

- Post hole digger PTO drive gearbox

- Heavy-duty gearbox for auger machines

-

Applications:

- - Agricultural PTO gearbox for auger drilling

- - Gearboxes for soil drilling equipment

-

- Auger drive gearboxes for post hole diggers

- Precision gearbox for earth augers

- Drivetrain solutions for post hole diggers

- Compact and efficient gearboxes for augers

- Maintenance-free gearboxes for drilling equipment

Minghua Gear or similar manufacturers might offer gearboxes that match these specifications for post hole diggers. Would you like to explore specific models or technical details for your project?

Packaging

Plastic sleeve covered on shaft.

Thick foam plate separate avoid collide.

Thick foam bag cover whole export plywood crate box.

Strength packing belt covered the crate box.

Testing Equipment

Full process inspection and testing.

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.