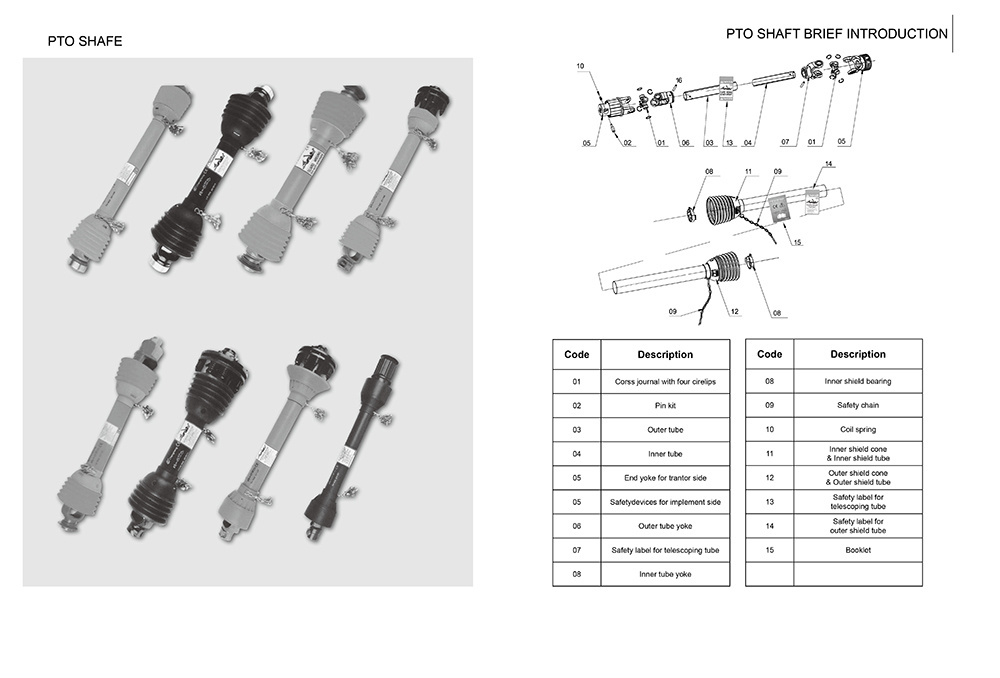

PTO Drive Shaft for Fertilizer Spreader

Key words:

PTO shaft

Classification:

Product Details

PTO Drive Shaft for Fertilizer Spreader

Minghua gear made PTO (Power Take-Off) drive shaft for a fertilizer spreader is a critical component that connects the tractor to the spreader, allowing the tractor's engine to power the spreader's mechanisms. The shaft transmits rotational power from the tractor's PTO output to the spreader, enabling the distribution of fertilizer across fields.

Here are the key components and considerations for a PTO drive shaft used in a fertilizer spreader:

Key Components:

- Shaft Tubes: These are typically telescopic, allowing for length adjustment to fit different tractor-to-spreader distances.

- Universal Joints (U-Joints): Located at each end of the shaft, these joints allow the drive shaft to transmit power even when the tractor and spreader are not perfectly aligned.

- Yokes: These connect the U-joints to the tractor and the spreader, ensuring a solid and secure attachment.

- Safety Guards: Most PTO shafts come with a protective cover or guard that prevents accidental contact with the rotating shaft, improving safety.

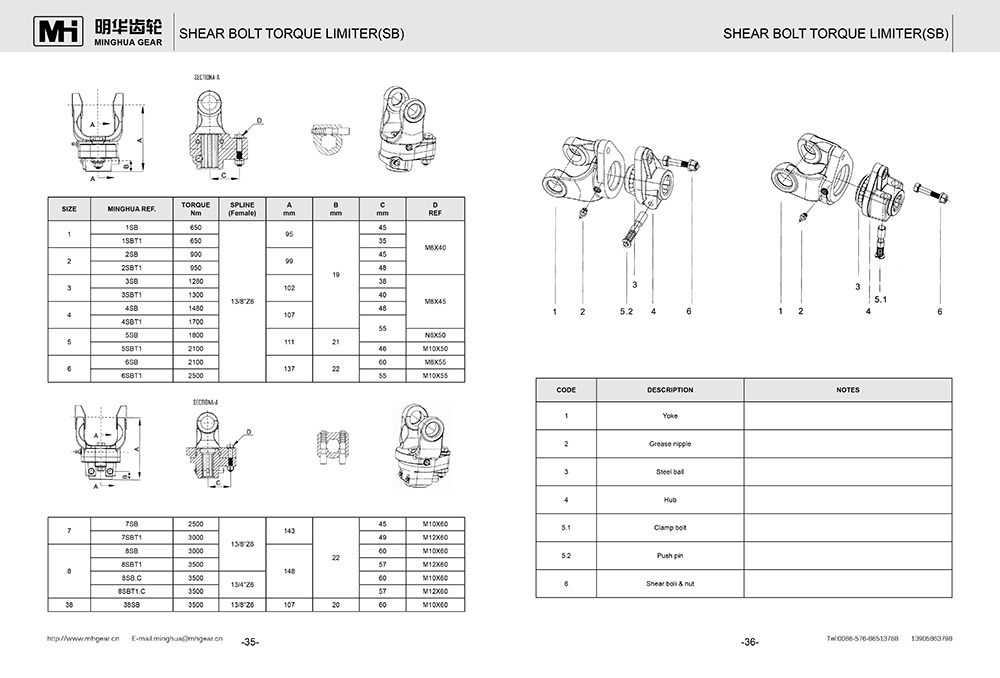

- Clutch/Overrunning Mechanism: Some shafts include a clutch or an overrunning device to protect the spreader from sudden stops or overloads.

-

Considerations for Selecting a PTO Shaft:

- Length: It must be the right length for your tractor and spreader combination. A shaft that’s too short or too long can cause operational problems.

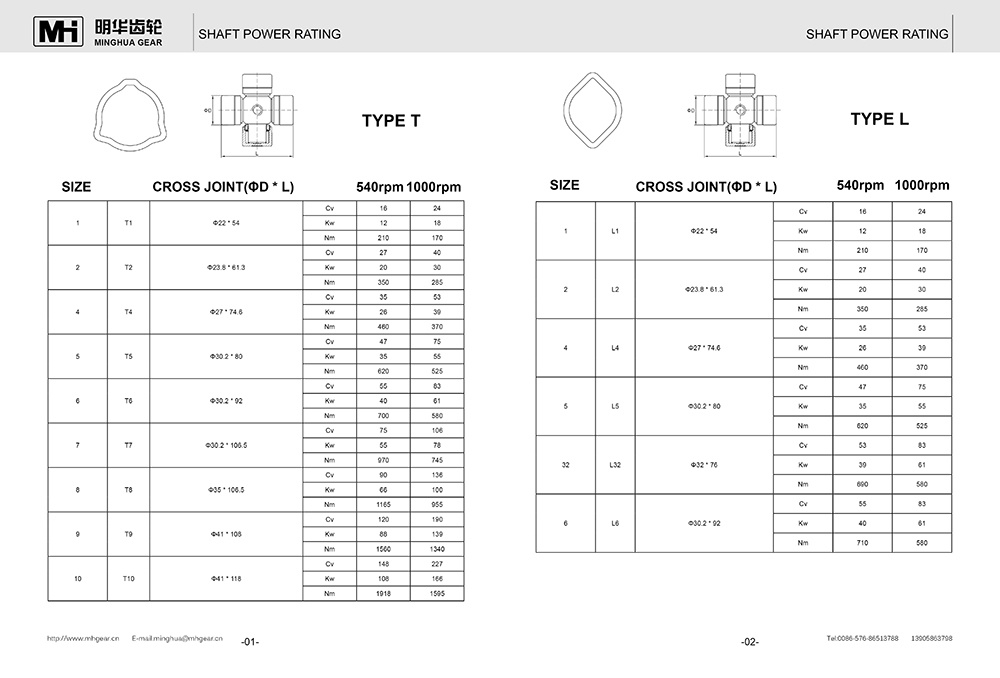

- Power Rating: Ensure the shaft is rated for the horsepower and torque that your tractor generates to avoid excessive wear or failure.

- Safety Features: Look for models with robust safety shields to reduce the risk of accidents during operation.

- Shear Pin or Slip Clutch: These features protect your spreader in case of an overload by preventing damage to the driveline or implement.

-

Applications:

Types of PTO Shafts for Fertilizer Spreader

-

540 RPM PTO Shaft

- This type is common for most small to medium-sized balers and is typically used on tractors with a 540 RPM PTO system. It is designed for standard baling tasks such as creating small to medium-sized round or square bales.

-

1000 RPM PTO Shaft

- For larger or high-capacity hay balers, a 1000 RPM PTO shaft is used, which provides more power. This higher-speed shaft is typically found on larger tractors and is used for heavy-duty baling operations that involve high-volume or dense bales.

-

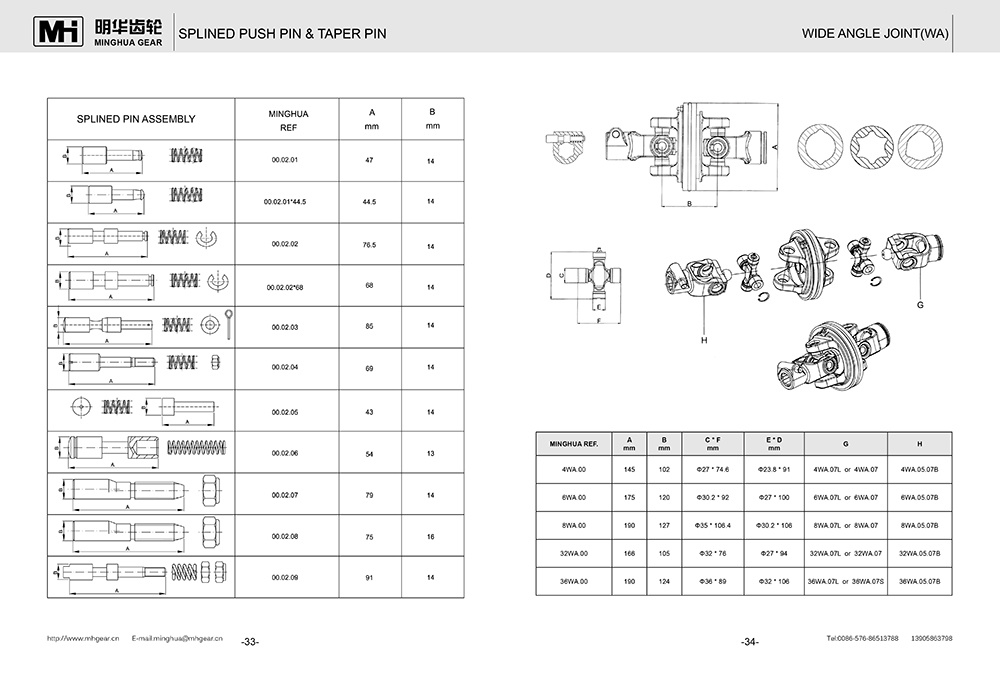

Wide-Angle PTO Shaft

- Some balers require a wide-angle PTO shaft, which allows for greater flexibility in movement and alignment. This type of shaft is useful when working in fields with tight turns or uneven terrain, providing more range of motion without causing excessive strain on the PTO components.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

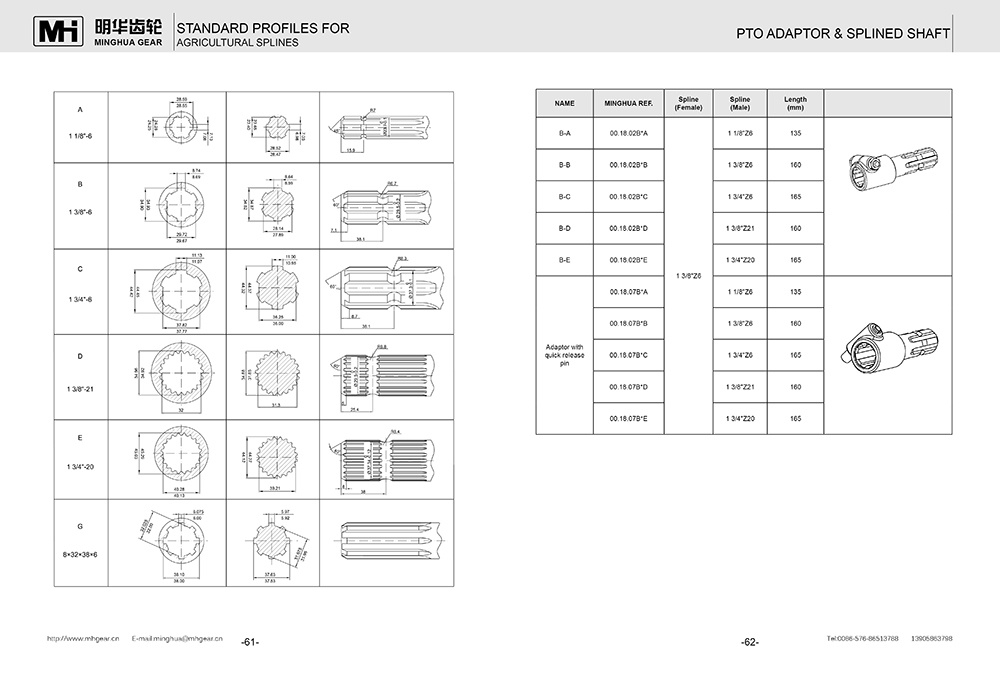

Part description

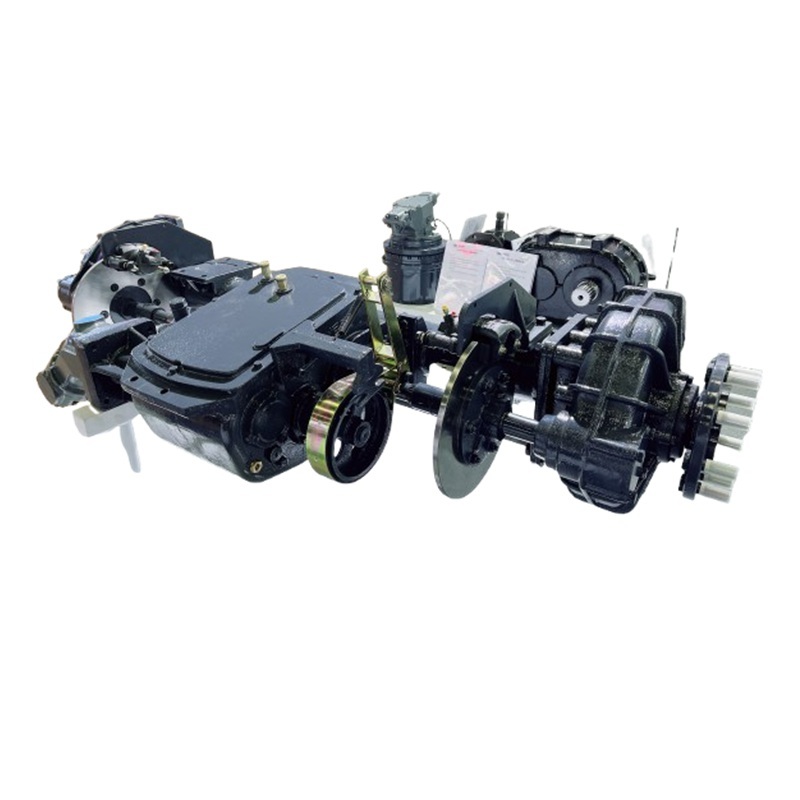

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

PTO Drive Shaft for Fertilizer Spreader

Key words:

PTO shaft

Classification:

Product Details

PTO Drive Shaft for Fertilizer Spreader

Minghua gear made PTO (Power Take-Off) drive shaft for a fertilizer spreader is a critical component that connects the tractor to the spreader, allowing the tractor's engine to power the spreader's mechanisms. The shaft transmits rotational power from the tractor's PTO output to the spreader, enabling the distribution of fertilizer across fields.

Here are the key components and considerations for a PTO drive shaft used in a fertilizer spreader:

Key Components:

- Shaft Tubes: These are typically telescopic, allowing for length adjustment to fit different tractor-to-spreader distances.

- Universal Joints (U-Joints): Located at each end of the shaft, these joints allow the drive shaft to transmit power even when the tractor and spreader are not perfectly aligned.

- Yokes: These connect the U-joints to the tractor and the spreader, ensuring a solid and secure attachment.

- Safety Guards: Most PTO shafts come with a protective cover or guard that prevents accidental contact with the rotating shaft, improving safety.

- Clutch/Overrunning Mechanism: Some shafts include a clutch or an overrunning device to protect the spreader from sudden stops or overloads.

-

Considerations for Selecting a PTO Shaft:

- Length: It must be the right length for your tractor and spreader combination. A shaft that’s too short or too long can cause operational problems.

- Power Rating: Ensure the shaft is rated for the horsepower and torque that your tractor generates to avoid excessive wear or failure.

- Safety Features: Look for models with robust safety shields to reduce the risk of accidents during operation.

- Shear Pin or Slip Clutch: These features protect your spreader in case of an overload by preventing damage to the driveline or implement.

-

Applications:

Types of PTO Shafts for Fertilizer Spreader

-

540 RPM PTO Shaft

- This type is common for most small to medium-sized balers and is typically used on tractors with a 540 RPM PTO system. It is designed for standard baling tasks such as creating small to medium-sized round or square bales.

-

1000 RPM PTO Shaft

- For larger or high-capacity hay balers, a 1000 RPM PTO shaft is used, which provides more power. This higher-speed shaft is typically found on larger tractors and is used for heavy-duty baling operations that involve high-volume or dense bales.

-

Wide-Angle PTO Shaft

- Some balers require a wide-angle PTO shaft, which allows for greater flexibility in movement and alignment. This type of shaft is useful when working in fields with tight turns or uneven terrain, providing more range of motion without causing excessive strain on the PTO components.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Part description

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.