Right Angle Gearbox for Rotary Mower Agriculture Machinery

Key words:

Gearboxes

Classification:

Product Details

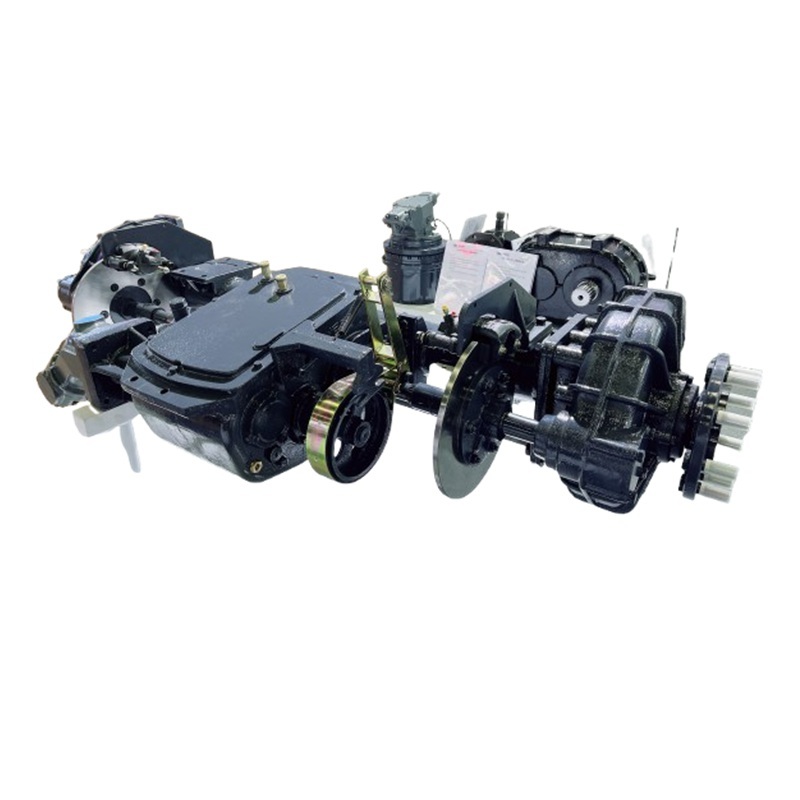

Right Angle Gearbox for Rotary Mower Agriculture Machinery

Gearbox housing build by material QT400 or QT450 ductile iron.

Gearbox shaft material use 40Cr or related steel.

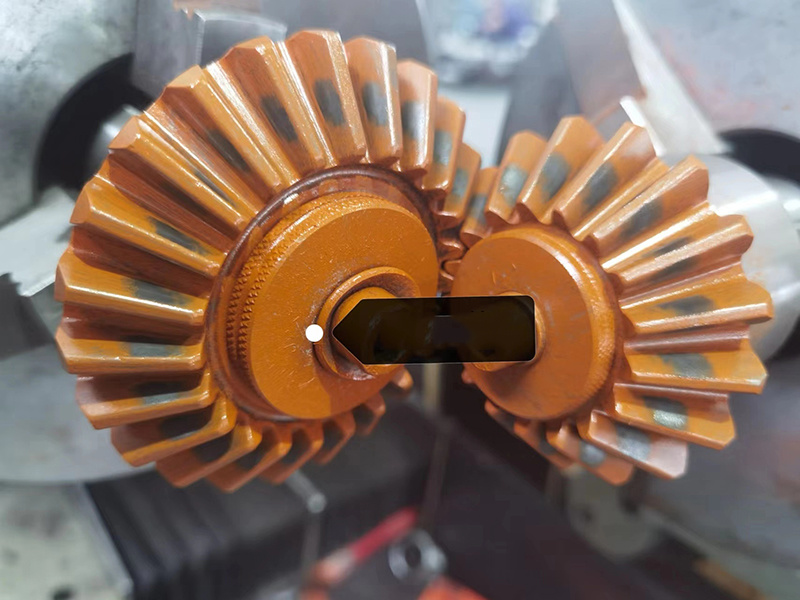

Gearbox gear material use 8620H or 20CrMnTi steel.

Heat treatment process available: normalizing, carburizing, quenching,

Generally, it meets the strength requirements of the material, and with excellent wear resistance.

Gearbox ratio is 1:1.93

Input spline shaft with cone base aequilate spline output shaft.

Applications,

Packaging

Plastic sleeve covered on shaft.

Thick foam plate separate avoid collide.

Thick foam bag cover whole export plywood crate box.

Strength packing belt covered the crate box.

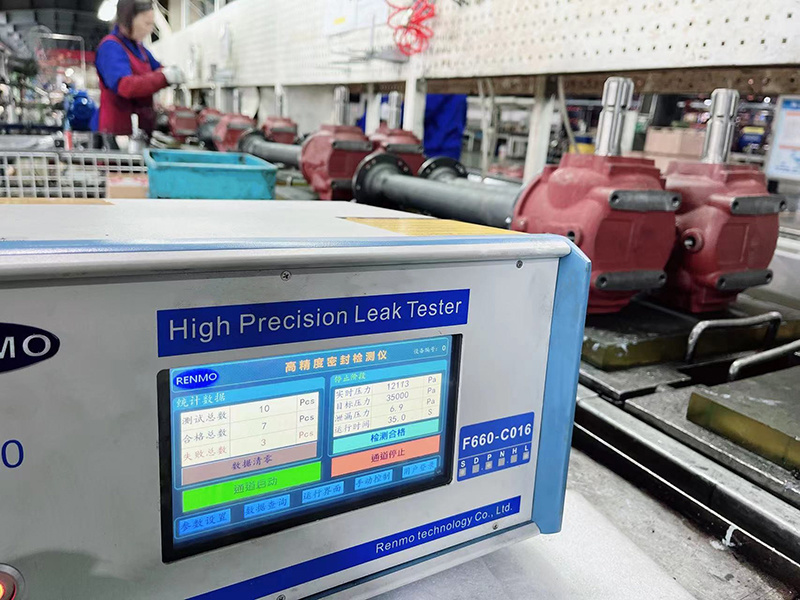

Testing Equipment

Full process inspection and testing.

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

Product video

Production Strength

Minghua gear is good at full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

1. What types of gearboxes do you manufacture?

We specialize in:

- Right-angle gearboxes for rotary cutters

- PTO drive gearboxes for finish mowers

- Aluminum gearboxes for fertilizer spreaders

- Cast iron gearboxes for post hole digger

- Aluminum or casting gearbox for corn headers.

We also offer customization options to suit specific requirements.

2. What materials are used in your gearboxes?

We use high-quality materials, such as:

- Cast iron and steel for durability in heavy-duty gearboxes.

- Lightweight yet robust aluminum for corrosion resistance in fertilizer spreaders.

3. Can you provide customized gearboxes?

Yes, we offer tailored solutions based on your specifications, including shaft design, gear ratios, and mounting configurations.

4. What’s the annual capacity of gearbox manufacturing?

We can manufacture 200000pcs gearbox per year.

5. Do you perform quality testing on your gearboxes?

Absolutely. We had our own testing lab with Brown&Sharp CMM, Zeiss CMM, Klingelnberg Gear inspection center…etc.

All gearboxes will perform related testing after each process, including metallographic test, noise test, backlash test, leakage proof test, vibration test ensure all data meets drawing requirement.

For more questions, contact with us today!

Right Angle Gearbox for Rotary Mower Agriculture Machinery

Key words:

Gearboxes

Classification:

Product Details

Right Angle Gearbox for Rotary Mower Agriculture Machinery

Gearbox housing build by material QT400 or QT450 ductile iron.

Gearbox shaft material use 40Cr or related steel.

Gearbox gear material use 8620H or 20CrMnTi steel.

Heat treatment process available: normalizing, carburizing, quenching,

Generally, it meets the strength requirements of the material, and with excellent wear resistance.

Gearbox ratio is 1:1.93

Input spline shaft with cone base aequilate spline output shaft.

Applications,

Packaging

Plastic sleeve covered on shaft.

Thick foam plate separate avoid collide.

Thick foam bag cover whole export plywood crate box.

Strength packing belt covered the crate box.

Testing Equipment

Full process inspection and testing.

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

Product video

Production Strength

Minghua gear is good at full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

1. What types of gearboxes do you manufacture?

We specialize in:

- Right-angle gearboxes for rotary cutters

- PTO drive gearboxes for finish mowers

- Aluminum gearboxes for fertilizer spreaders

- Cast iron gearboxes for post hole digger

- Aluminum or casting gearbox for corn headers.

We also offer customization options to suit specific requirements.

2. What materials are used in your gearboxes?

We use high-quality materials, such as:

- Cast iron and steel for durability in heavy-duty gearboxes.

- Lightweight yet robust aluminum for corrosion resistance in fertilizer spreaders.

3. Can you provide customized gearboxes?

Yes, we offer tailored solutions based on your specifications, including shaft design, gear ratios, and mounting configurations.

4. What’s the annual capacity of gearbox manufacturing?

We can manufacture 200000pcs gearbox per year.

5. Do you perform quality testing on your gearboxes?

Absolutely. We had our own testing lab with Brown&Sharp CMM, Zeiss CMM, Klingelnberg Gear inspection center…etc.

All gearboxes will perform related testing after each process, including metallographic test, noise test, backlash test, leakage proof test, vibration test ensure all data meets drawing requirement.

For more questions, contact with us today!

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.