Aluminum Gearbox for Corn Header Harvester

Key words:

Gearboxes

Classification:

Product Details

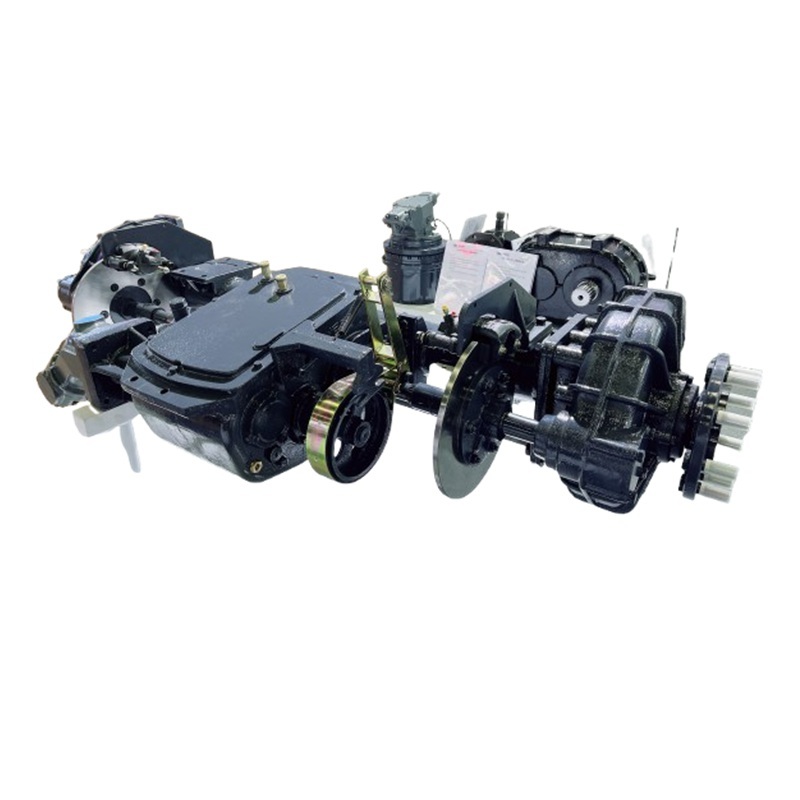

Aluminum Gearbox for Corn Header Harvester

An aluminum corn header gearbox is a crucial component in agricultural machinery, specifically in corn harvesters.

This type of gearbox is responsible for driving the row units that harvest the corn.

Key words :

Corn header gearboxes

- Agricultural gearboxes for corn headers

- Combine harvester gearbox

- Corn harvester drivetrain components

- Precision gearbox for corn headers

- Rotary gearboxes for agricultural machinery

- Durable corn header PTO gearbox

- Replacement gearboxes for corn headers

Applications:

- **Row Units**: These gearboxes are typically used to drive the row units on corn headers, which are responsible for picking and transporting corn stalks to the processing area of the harvester.

- **Combine Harvesters**: Compatible with various models of combine harvesters, these gearboxes help in efficient harvesting by ensuring smooth and reliable operation of the header.

- Corn header gearbox manufacturers

- Agricultural gearbox supplier

- Wholesale gearbox for agricultural equipment

- OEM corn header gearboxes

- Custom gearbox manufacturing for harvesters

- Affordable gearbox for corn harvesters

- Gearbox supplier for farming equipment

Packaging

Plastic sleeve covered on shaft.

Thick foam plate separate avoid collide.

Thick foam bag cover whole export plywood crate box.

Strength packing belt covered the crate box.

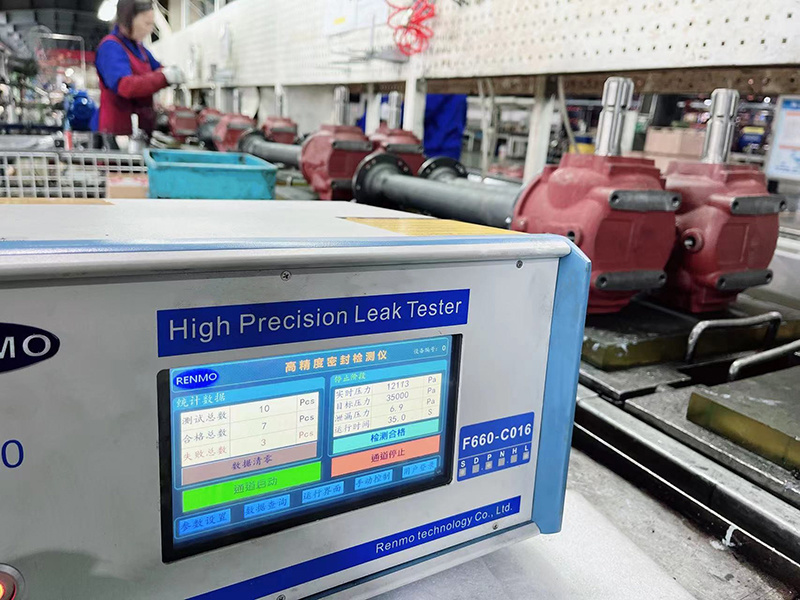

Testing Equipment

Full process inspection and testing.

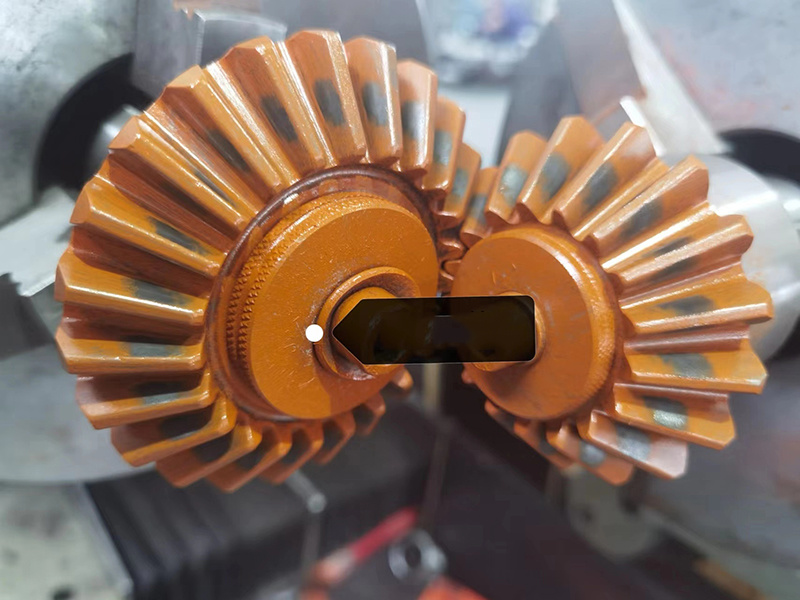

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

Aluminum Gearbox for Corn Header Harvester

Key words:

Gearboxes

Classification:

Product Details

Aluminum Gearbox for Corn Header Harvester

An aluminum corn header gearbox is a crucial component in agricultural machinery, specifically in corn harvesters.

This type of gearbox is responsible for driving the row units that harvest the corn.

Key words :

Corn header gearboxes

- Agricultural gearboxes for corn headers

- Combine harvester gearbox

- Corn harvester drivetrain components

- Precision gearbox for corn headers

- Rotary gearboxes for agricultural machinery

- Durable corn header PTO gearbox

- Replacement gearboxes for corn headers

Applications:

- **Row Units**: These gearboxes are typically used to drive the row units on corn headers, which are responsible for picking and transporting corn stalks to the processing area of the harvester.

- **Combine Harvesters**: Compatible with various models of combine harvesters, these gearboxes help in efficient harvesting by ensuring smooth and reliable operation of the header.

- Corn header gearbox manufacturers

- Agricultural gearbox supplier

- Wholesale gearbox for agricultural equipment

- OEM corn header gearboxes

- Custom gearbox manufacturing for harvesters

- Affordable gearbox for corn harvesters

- Gearbox supplier for farming equipment

Packaging

Plastic sleeve covered on shaft.

Thick foam plate separate avoid collide.

Thick foam bag cover whole export plywood crate box.

Strength packing belt covered the crate box.

Testing Equipment

Full process inspection and testing.

Include gear teeth contact pattern testing, CMM inspection, Metallographic analysis and testing,torque testing, Gearbox oil leakage testing, Gearbox noise testing, Paint adhesion testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.