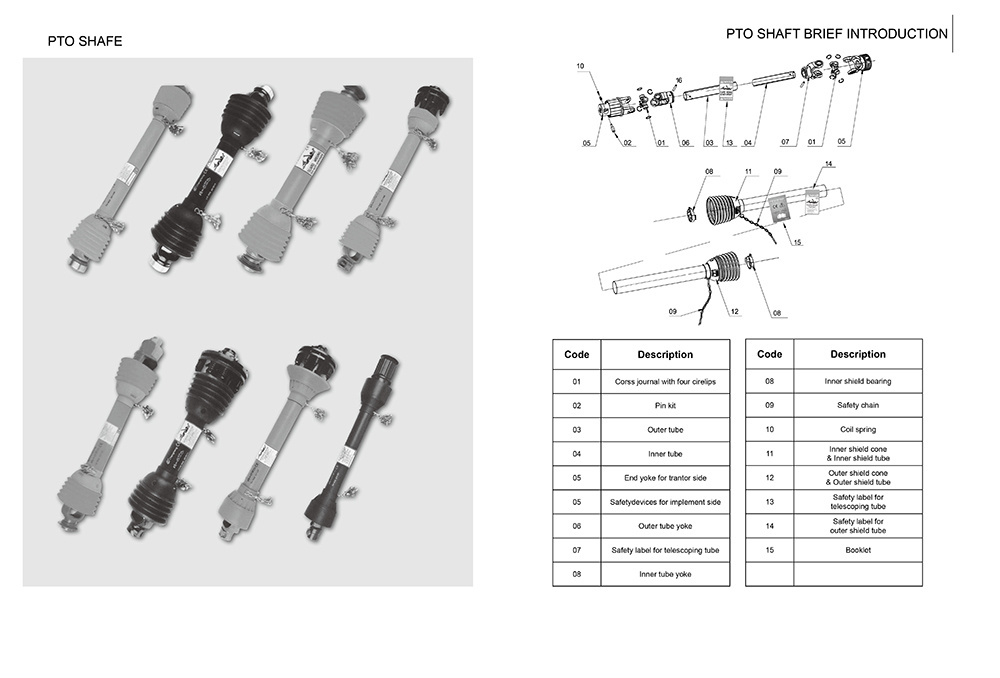

PTO Drive Shaft for Flail Mower Tractor Attachment

Key words:

PTO shaft

Classification:

Product Details

PTO Drive Shaft for Flail Mower Tractor Attachment

Minghua Gear made PTO drive shaft for a flail mower is essential for transferring power from the tractor’s engine to the mower’s cutting mechanism. Here's a detailed breakdown of what to consider when purchasing or maintaining a PTO drive shaft for this type of attachment:

Key Factors to Consider:

-

PTO Shaft Length:

- The shaft must fit properly between the tractor and the flail mower attachment. A shaft that is too long or too short can cause operational issues or damage equipment.

- Many PTO shafts are telescopic, allowing for adjustment to the correct length. Make sure to measure the distance from the tractor’s PTO output to the mower’s gearbox input when both are connected.

-

Power Rating (Horsepower):

- The shaft must be capable of handling the horsepower of the tractor. Mismatched ratings can lead to mechanical failure.

- Ensure the PTO shaft matches the horsepower requirements of the flail mower. For example, for light-duty mowers, a lower-rated shaft may be sufficient, while heavy-duty mowers will need a stronger shaft.

-

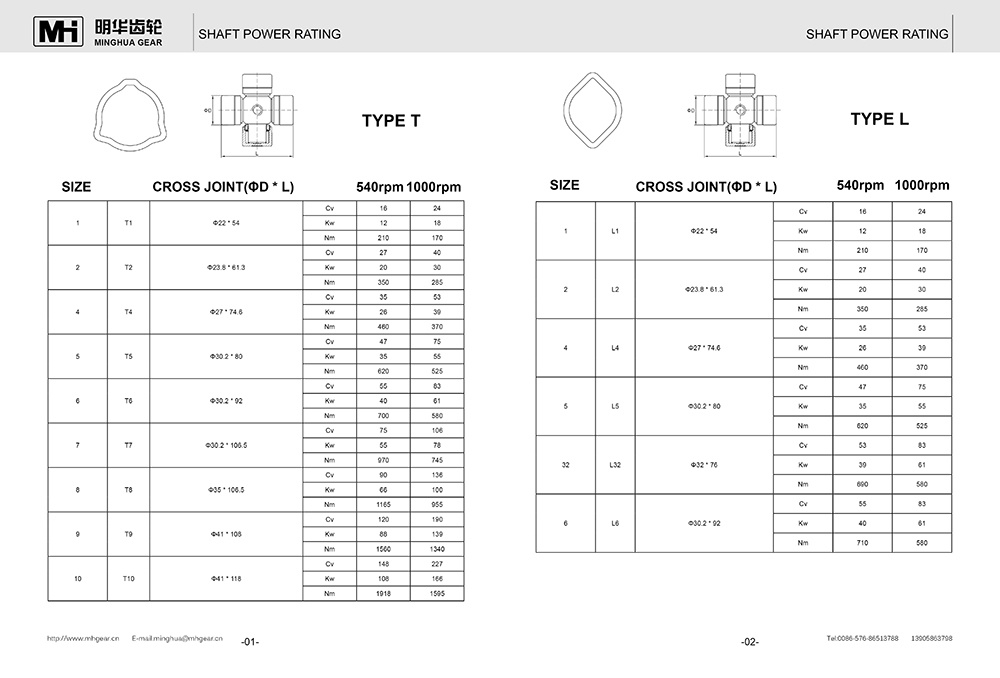

PTO Speed (RPM):

- PTO drive shafts commonly run at either 540 RPM or 1,000 RPM. Ensure your tractor and flail mower both operate at the same speed and that the shaft is designed for it.

- Double-check the mower’s specifications to confirm this.

-

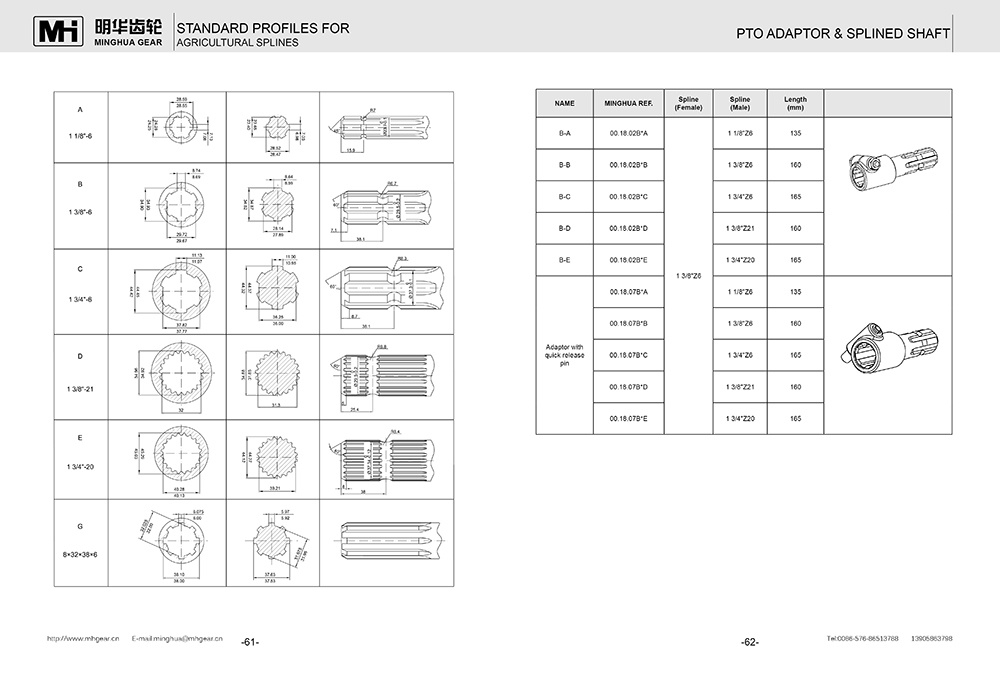

Shaft Size and Series:

- PTO drive shafts come in different series, each designed to handle specific loads. Common sizes include Series 1, Series 4, Series 6, etc.

- A Series 6 shaft, for instance, is suited for more heavy-duty applications, while a Series 4 may be better for light to medium loads.

-

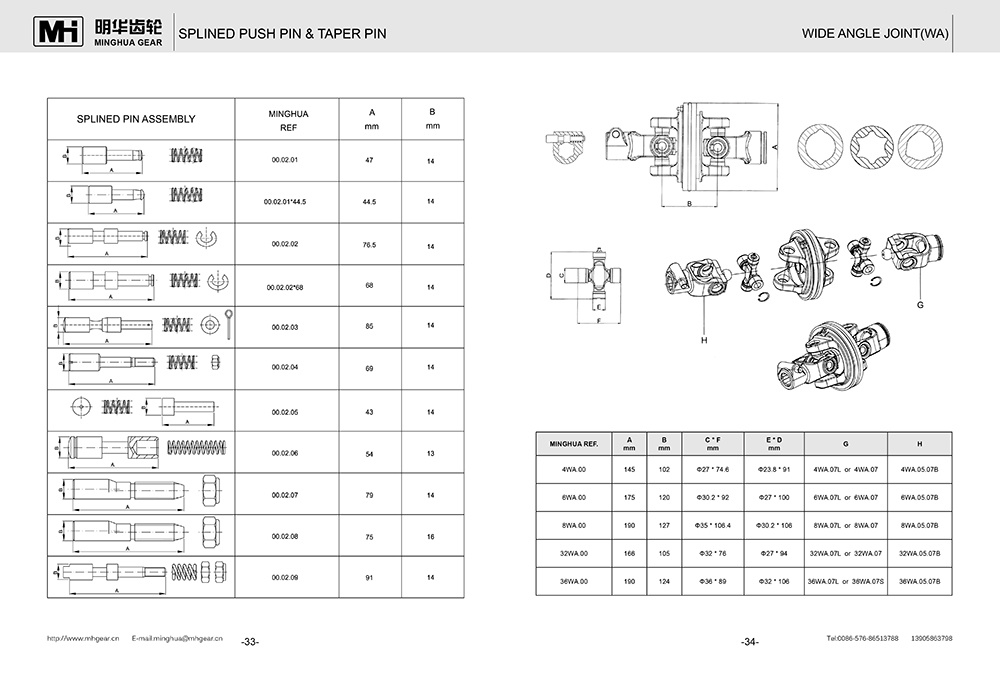

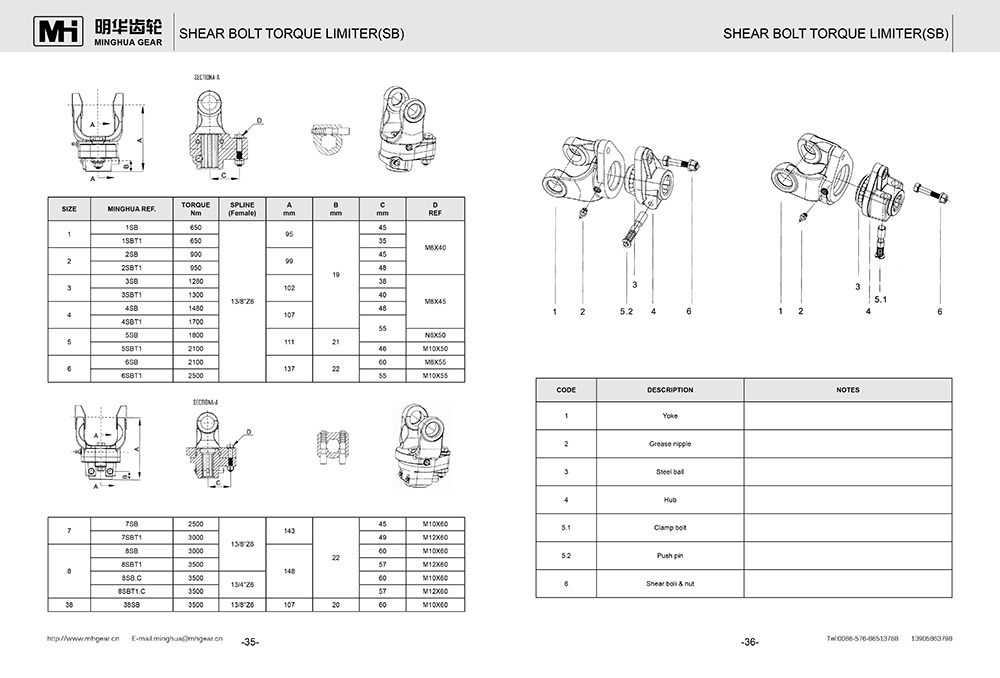

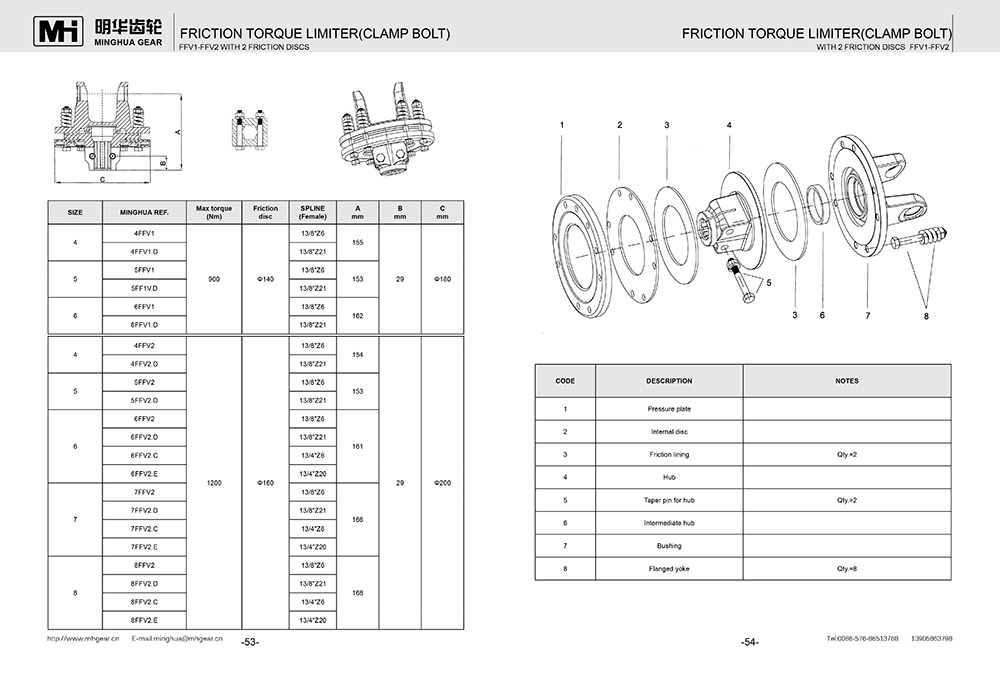

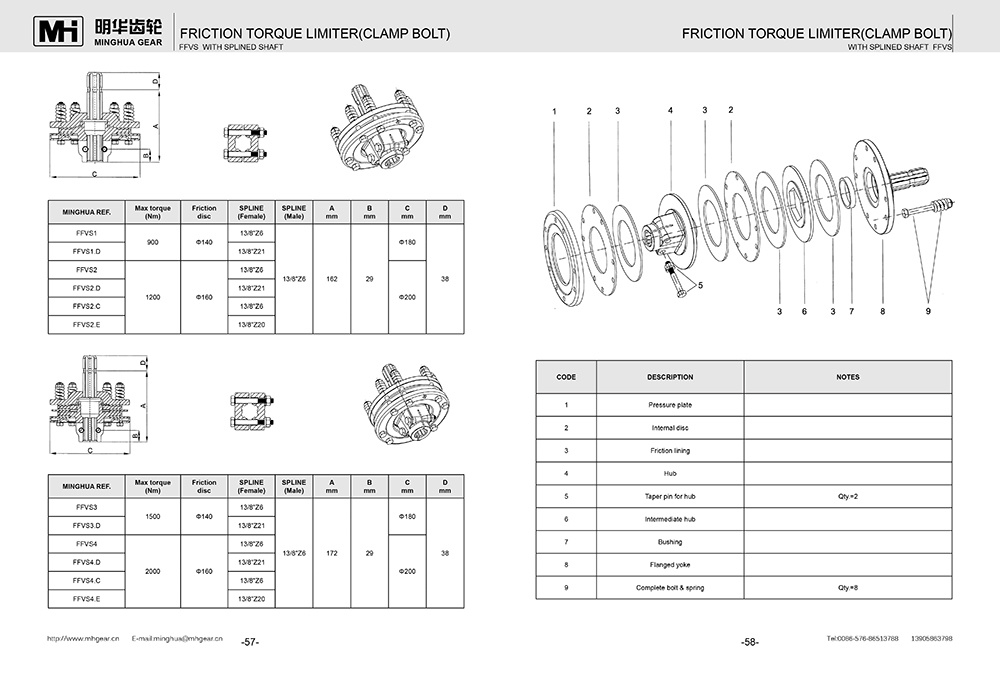

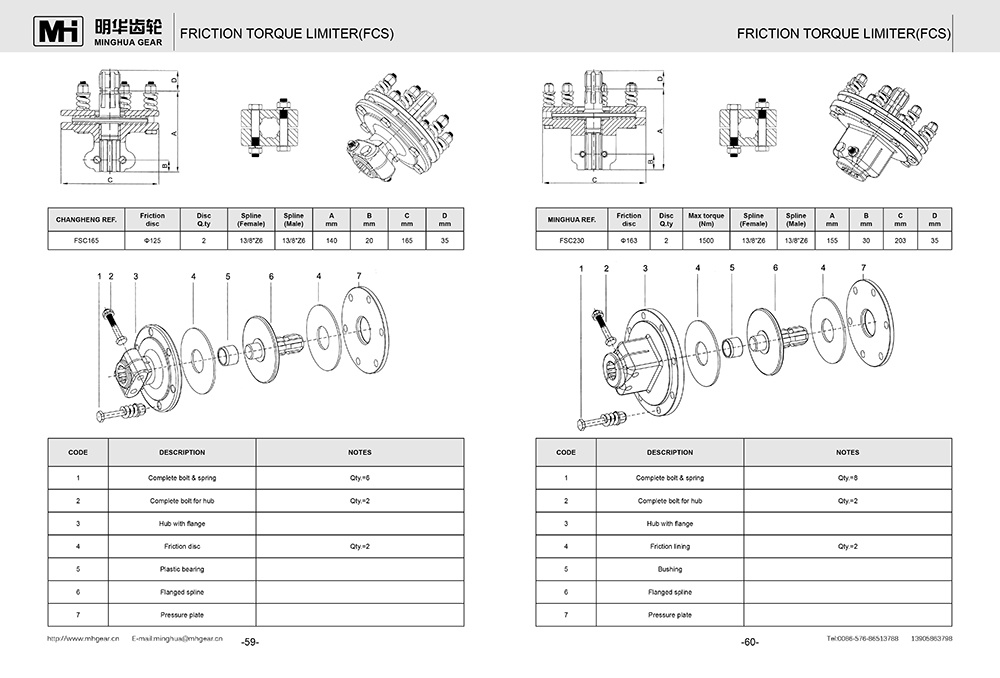

Connection Type (Yokes & Clutches):

- Yoke Type: Check the yoke ends to ensure they match the output on your tractor and the input on the flail mower gearbox. Common connections include smooth bores, splined connections, and quick-connect options.

- Slip Clutches or Shear Bolts: These provide protection by preventing damage to the mower or shaft if the blades encounter something too hard to cut. If your mower requires this, ensure the PTO shaft includes the appropriate protective mechanism.

-

Safety Shields:

- Ensure that the shaft includes safety shields to protect operators from the rotating parts of the PTO. These covers are crucial for safe operation and should be intact.

-

Grease Points and Maintenance:

- Regular lubrication of the universal joints and other moving parts of the PTO shaft is essential for smooth operation and a long lifespan. Check that the PTO shaft you choose has easily accessible grease points.

Applications:

Types of PTO Shafts for Flail Mower

-

540 RPM PTO Shaft

- This type is common for most small to medium-sized balers and is typically used on tractors with a 540 RPM PTO system. It is designed for standard baling tasks such as creating small to medium-sized round or square bales.

-

1000 RPM PTO Shaft

- For larger or high-capacity hay balers, a 1000 RPM PTO shaft is used, which provides more power. This higher-speed shaft is typically found on larger tractors and is used for heavy-duty baling operations that involve high-volume or dense bales.

-

Wide-Angle PTO Shaft

- Some balers require a wide-angle PTO shaft, which allows for greater flexibility in movement and alignment. This type of shaft is useful when working in fields with tight turns or uneven terrain, providing more range of motion without causing excessive strain on the PTO components.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Part description

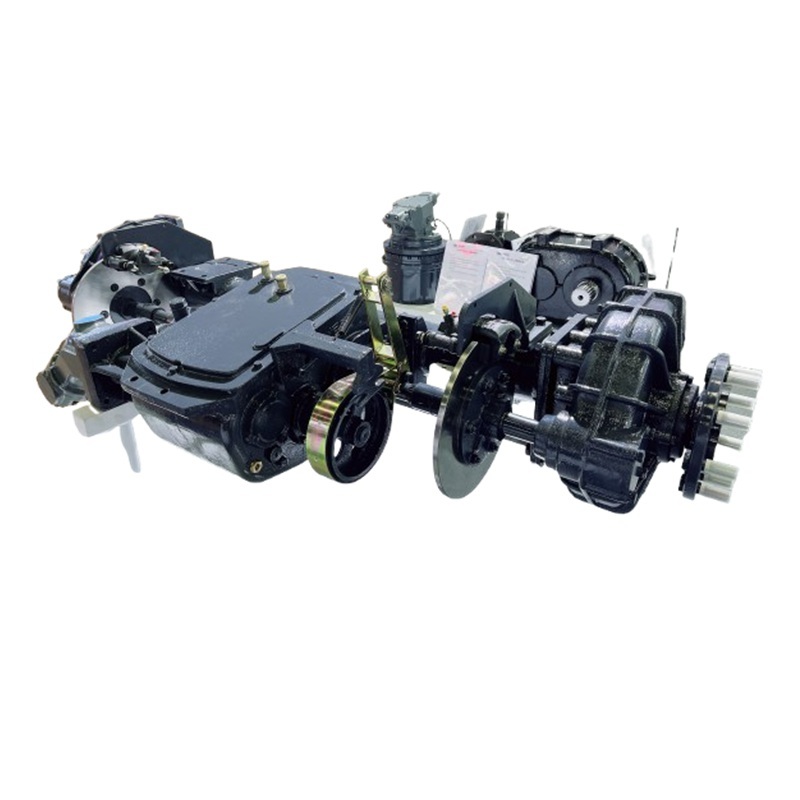

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

PTO Drive Shaft for Flail Mower Tractor Attachment

Key words:

PTO shaft

Classification:

Product Details

PTO Drive Shaft for Flail Mower Tractor Attachment

Minghua Gear made PTO drive shaft for a flail mower is essential for transferring power from the tractor’s engine to the mower’s cutting mechanism. Here's a detailed breakdown of what to consider when purchasing or maintaining a PTO drive shaft for this type of attachment:

Key Factors to Consider:

-

PTO Shaft Length:

- The shaft must fit properly between the tractor and the flail mower attachment. A shaft that is too long or too short can cause operational issues or damage equipment.

- Many PTO shafts are telescopic, allowing for adjustment to the correct length. Make sure to measure the distance from the tractor’s PTO output to the mower’s gearbox input when both are connected.

-

Power Rating (Horsepower):

- The shaft must be capable of handling the horsepower of the tractor. Mismatched ratings can lead to mechanical failure.

- Ensure the PTO shaft matches the horsepower requirements of the flail mower. For example, for light-duty mowers, a lower-rated shaft may be sufficient, while heavy-duty mowers will need a stronger shaft.

-

PTO Speed (RPM):

- PTO drive shafts commonly run at either 540 RPM or 1,000 RPM. Ensure your tractor and flail mower both operate at the same speed and that the shaft is designed for it.

- Double-check the mower’s specifications to confirm this.

-

Shaft Size and Series:

- PTO drive shafts come in different series, each designed to handle specific loads. Common sizes include Series 1, Series 4, Series 6, etc.

- A Series 6 shaft, for instance, is suited for more heavy-duty applications, while a Series 4 may be better for light to medium loads.

-

Connection Type (Yokes & Clutches):

- Yoke Type: Check the yoke ends to ensure they match the output on your tractor and the input on the flail mower gearbox. Common connections include smooth bores, splined connections, and quick-connect options.

- Slip Clutches or Shear Bolts: These provide protection by preventing damage to the mower or shaft if the blades encounter something too hard to cut. If your mower requires this, ensure the PTO shaft includes the appropriate protective mechanism.

-

Safety Shields:

- Ensure that the shaft includes safety shields to protect operators from the rotating parts of the PTO. These covers are crucial for safe operation and should be intact.

-

Grease Points and Maintenance:

- Regular lubrication of the universal joints and other moving parts of the PTO shaft is essential for smooth operation and a long lifespan. Check that the PTO shaft you choose has easily accessible grease points.

Applications:

Types of PTO Shafts for Flail Mower

-

540 RPM PTO Shaft

- This type is common for most small to medium-sized balers and is typically used on tractors with a 540 RPM PTO system. It is designed for standard baling tasks such as creating small to medium-sized round or square bales.

-

1000 RPM PTO Shaft

- For larger or high-capacity hay balers, a 1000 RPM PTO shaft is used, which provides more power. This higher-speed shaft is typically found on larger tractors and is used for heavy-duty baling operations that involve high-volume or dense bales.

-

Wide-Angle PTO Shaft

- Some balers require a wide-angle PTO shaft, which allows for greater flexibility in movement and alignment. This type of shaft is useful when working in fields with tight turns or uneven terrain, providing more range of motion without causing excessive strain on the PTO components.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Part description

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.