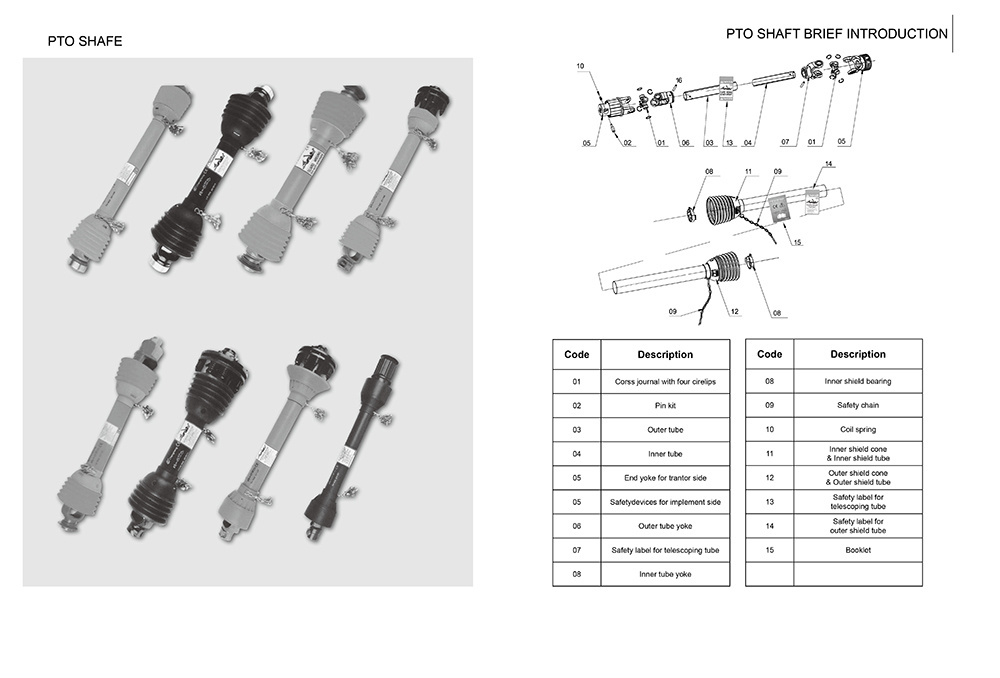

Tractor PTO Shaft Drive Shaft with 1 3/8 Spline Yoke

Key words:

PTO shaft

Classification:

Product Details

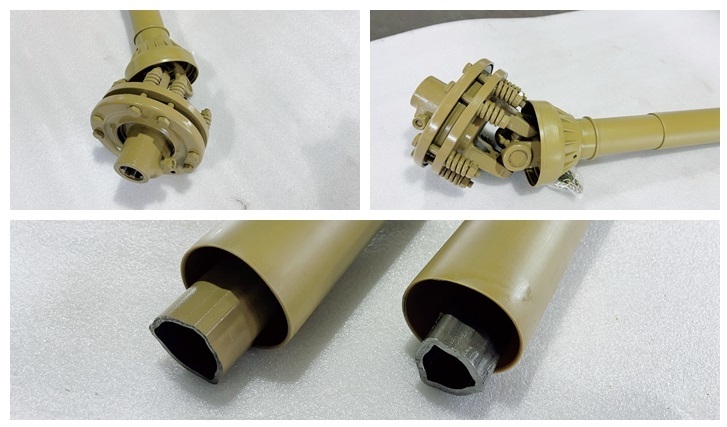

Tractor PTO Shaft Drive Shaft with 1 3/8 Spline Yoke

Minghua gear made tractor PTO drive shaft is a mechanical component used to transfer power from a tractor to an implement or machinery, such as mowers, balers, spreaders, and augers. The PTO (Power Take-Off) system allows tractors to operate attachments by transmitting engine power through the drive shaft, which then powers the attached equipment.

Here are some key components and considerations for selecting a PTO shaft for a rotary harrow:

Key Components of a Tractor PTO Drive Shaft

-

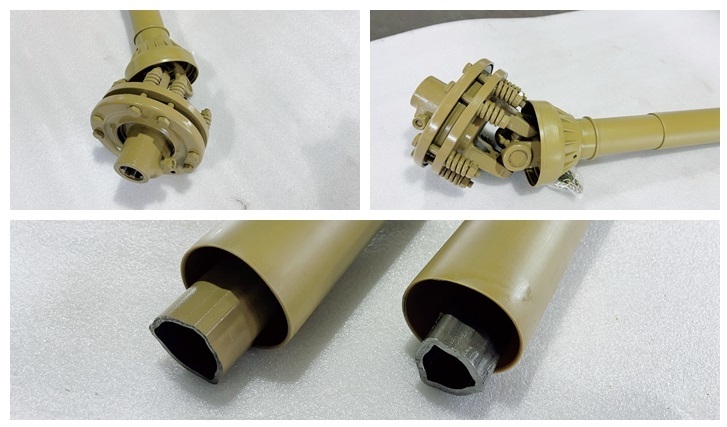

Shaft

- The core component of the PTO system, responsible for transferring torque from the tractor to the attached implement. The shaft consists of two parts: the inner and outer tubes, which can slide in and out to adjust to different working lengths.

-

Universal Joints (U-joints)

- Located at both ends of the shaft, these joints allow the shaft to transmit power at different angles. They are designed to maintain smooth rotational motion despite the misalignment between the tractor and implement.

-

Yokes

- Yokes are attached to both ends of the PTO shaft. One yoke connects to the tractor's PTO stub shaft, and the other connects to the implement's input shaft. The yokes allow the shaft to rotate and transmit power efficiently.

-

Safety Shield or Guard

- A protective plastic or metal shield surrounds the rotating shaft to prevent accidental contact with the spinning components. Safety shields reduce the risk of injury during operation.

-

Shear Bolt or Slip Clutch

- These are safety features designed to prevent overloading the implement. A shear bolt will break when excessive torque is applied, stopping the shaft and preventing damage. A slip clutch performs a similar function but uses friction to disengage the shaft under excessive load.

-

Quick Disconnect Coupler

- A feature that allows for quick attachment or removal of the PTO shaft from the tractor or implement without the need for tools, improving convenience and ease of use.

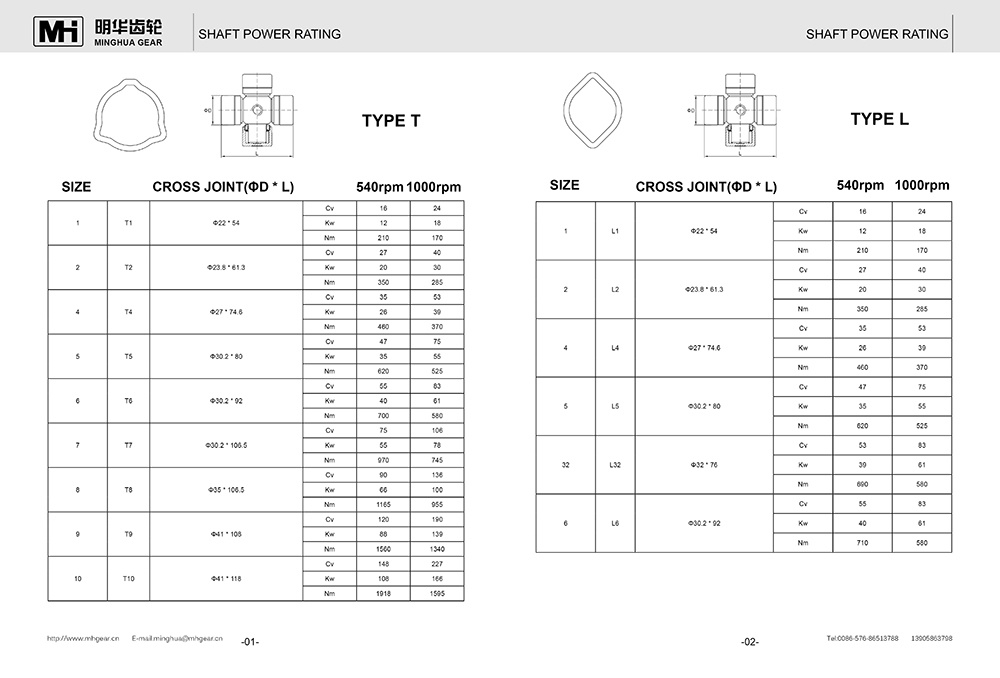

Types of PTO Drive Shafts

-

540 RPM PTO Shaft

- This is the most common type used on smaller tractors and implements. It operates at a rotational speed of 540 RPM, suitable for many standard agricultural attachments like mowers and balers.

-

1000 RPM PTO Shaft

- This is used on larger tractors and more demanding implements that require greater power transmission. The higher rotational speed (1000 RPM) is used for heavy-duty applications like large balers, forage harvesters, and some tillage equipment.

-

Dual-Speed PTO

- Some tractors are equipped with a dual-speed PTO, allowing the operator to switch between 540 RPM and 1000 RPM depending on the type of implement being used

Safety Precautions for PTO Shafts

- Always keep the safety shields in place: This reduces the risk of entanglement and severe injury.

- Turn off the tractor before attaching or detaching the PTO shaft.

- Avoid wearing loose clothing when working near PTO shafts to prevent accidental entanglement.

- Regularly inspect the PTO shaft, U-joints, and yokes for wear and tear, and ensure proper lubrication.

PTO shaft apply in agricultural Equipment

- Rotary Mowers: Connects the tractor's PTO to the mower, powering the cutting blades.

- Rotary Tillers: Transfers power to till the soil, preparing it for planting.

- Balers: Powers the mechanism that compacts and ties bales of hay or straw.

- Spreaders: Used in manure or fertilizer spreaders to drive the spreading mechanism.

- Post Hole Diggers: Powers the auger to dig holes for fence posts or planting.

- Grain Augers: Transfers power to move grain from trucks or bins into storage.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

PTO Shaft Description

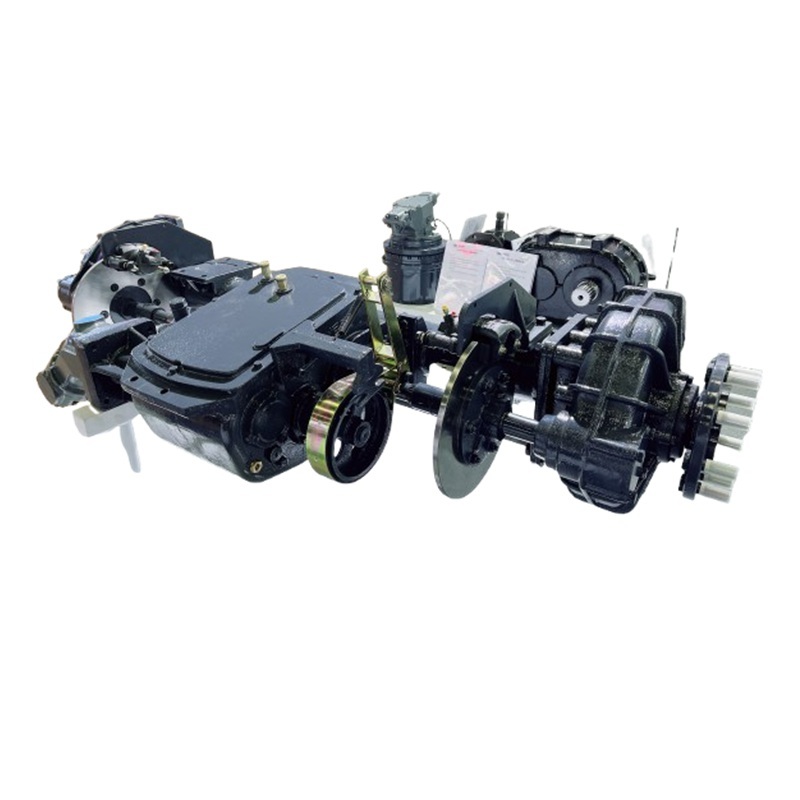

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

Previous

Tractor PTO Shaft Drive Shaft with 1 3/8 Spline Yoke

Key words:

PTO shaft

Classification:

Product Details

Tractor PTO Shaft Drive Shaft with 1 3/8 Spline Yoke

Minghua gear made tractor PTO drive shaft is a mechanical component used to transfer power from a tractor to an implement or machinery, such as mowers, balers, spreaders, and augers. The PTO (Power Take-Off) system allows tractors to operate attachments by transmitting engine power through the drive shaft, which then powers the attached equipment.

Here are some key components and considerations for selecting a PTO shaft for a rotary harrow:

Key Components of a Tractor PTO Drive Shaft

-

Shaft

- The core component of the PTO system, responsible for transferring torque from the tractor to the attached implement. The shaft consists of two parts: the inner and outer tubes, which can slide in and out to adjust to different working lengths.

-

Universal Joints (U-joints)

- Located at both ends of the shaft, these joints allow the shaft to transmit power at different angles. They are designed to maintain smooth rotational motion despite the misalignment between the tractor and implement.

-

Yokes

- Yokes are attached to both ends of the PTO shaft. One yoke connects to the tractor's PTO stub shaft, and the other connects to the implement's input shaft. The yokes allow the shaft to rotate and transmit power efficiently.

-

Safety Shield or Guard

- A protective plastic or metal shield surrounds the rotating shaft to prevent accidental contact with the spinning components. Safety shields reduce the risk of injury during operation.

-

Shear Bolt or Slip Clutch

- These are safety features designed to prevent overloading the implement. A shear bolt will break when excessive torque is applied, stopping the shaft and preventing damage. A slip clutch performs a similar function but uses friction to disengage the shaft under excessive load.

-

Quick Disconnect Coupler

- A feature that allows for quick attachment or removal of the PTO shaft from the tractor or implement without the need for tools, improving convenience and ease of use.

Types of PTO Drive Shafts

-

540 RPM PTO Shaft

- This is the most common type used on smaller tractors and implements. It operates at a rotational speed of 540 RPM, suitable for many standard agricultural attachments like mowers and balers.

-

1000 RPM PTO Shaft

- This is used on larger tractors and more demanding implements that require greater power transmission. The higher rotational speed (1000 RPM) is used for heavy-duty applications like large balers, forage harvesters, and some tillage equipment.

-

Dual-Speed PTO

- Some tractors are equipped with a dual-speed PTO, allowing the operator to switch between 540 RPM and 1000 RPM depending on the type of implement being used

Safety Precautions for PTO Shafts

- Always keep the safety shields in place: This reduces the risk of entanglement and severe injury.

- Turn off the tractor before attaching or detaching the PTO shaft.

- Avoid wearing loose clothing when working near PTO shafts to prevent accidental entanglement.

- Regularly inspect the PTO shaft, U-joints, and yokes for wear and tear, and ensure proper lubrication.

PTO shaft apply in agricultural Equipment

- Rotary Mowers: Connects the tractor's PTO to the mower, powering the cutting blades.

- Rotary Tillers: Transfers power to till the soil, preparing it for planting.

- Balers: Powers the mechanism that compacts and ties bales of hay or straw.

- Spreaders: Used in manure or fertilizer spreaders to drive the spreading mechanism.

- Post Hole Diggers: Powers the auger to dig holes for fence posts or planting.

- Grain Augers: Transfers power to move grain from trucks or bins into storage.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

PTO Shaft Description

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.