PTO Shaft for Hay Baler

Key words:

PTO shaft

Classification:

Product Details

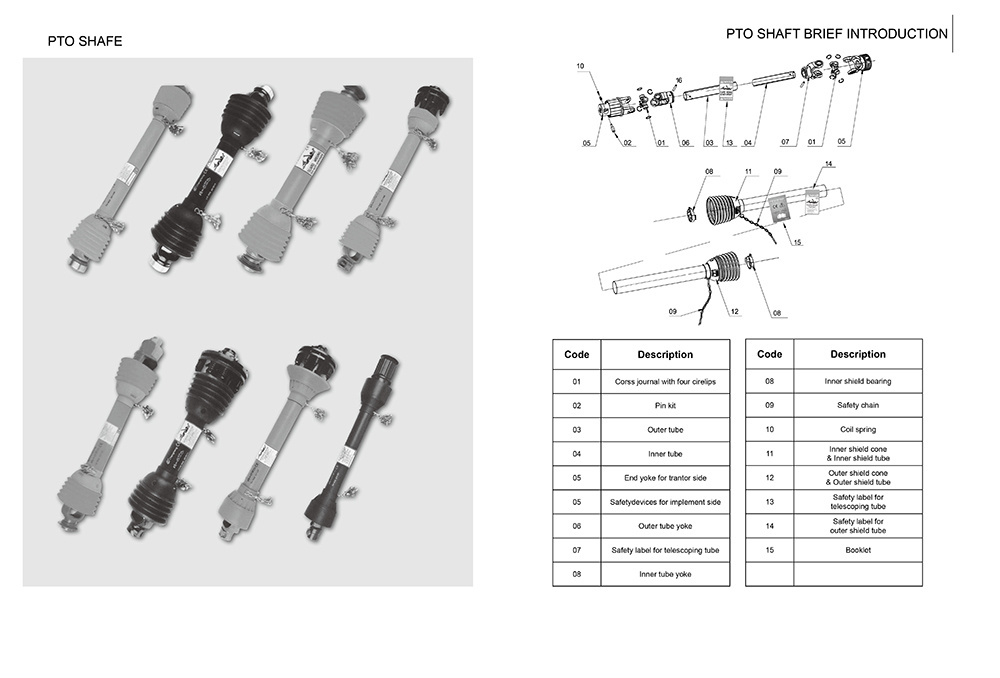

PTO Shaft for Hay Baler

Minghua Gear made PTO shaft for a hay baler is a critical component that connects the tractor's Power Take-Off (PTO) to the baler, transmitting mechanical power from the tractor to the baler’s internal mechanisms. This power enables the baler to operate its various functions, such as gathering hay, compressing it into bales, and tying or wrapping the bales.

Types of PTO Shafts for Hay Balers

-

540 RPM PTO Shaft

- This type is common for most small to medium-sized balers and is typically used on tractors with a 540 RPM PTO system. It is designed for standard baling tasks such as creating small to medium-sized round or square bales.

-

1000 RPM PTO Shaft

- For larger or high-capacity hay balers, a 1000 RPM PTO shaft is used, which provides more power. This higher-speed shaft is typically found on larger tractors and is used for heavy-duty baling operations that involve high-volume or dense bales.

-

Wide-Angle PTO Shaft

- Some balers require a wide-angle PTO shaft, which allows for greater flexibility in movement and alignment. This type of shaft is useful when working in fields with tight turns or uneven terrain, providing more range of motion without causing excessive strain on the PTO components.

Key Components of a PTO Shaft for a Hay Baler

-

Telescoping Shaft

- The PTO shaft typically consists of two telescoping parts (inner and outer tubes) that allow for length adjustments as the tractor moves, ensuring constant power transmission even when working on uneven ground or during tight turns.

-

Universal Joints (U-Joints)

- Located at both ends of the PTO shaft, the U-joints allow the shaft to transmit rotational power while accommodating slight misalignments between the tractor and the baler. This flexibility is necessary for smooth operation, especially on uneven terrain.

-

Yokes

- The yokes are mounted on the ends of the PTO shaft to connect it to both the tractor’s PTO output shaft and the baler’s input shaft. The yokes, along with the U-joints, allow for rotational movement and power transfer.

-

Safety Guard

- The PTO shaft is usually enclosed by a protective guard or safety shield that helps prevent accidental contact with the spinning shaft. This is an important safety feature, as the rotating shaft poses a significant hazard during operation.

-

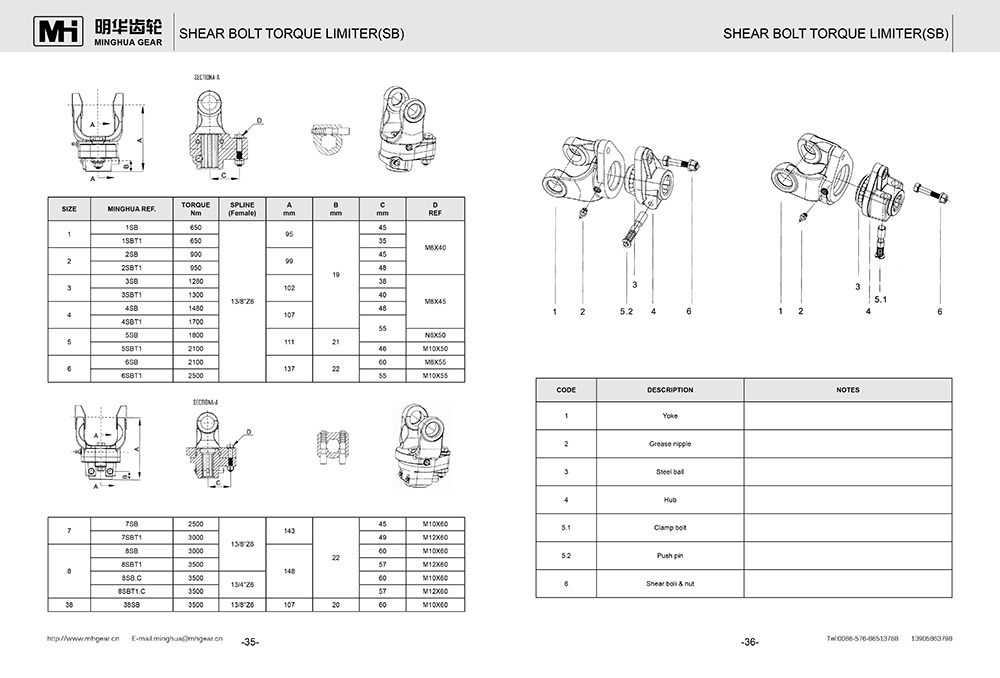

Shear Bolt or Slip Clutch

- Shear Bolt: A shear bolt is a safety feature that protects the PTO shaft, the tractor, and the baler from damage. If the baler encounters an obstruction (such as a large, unbreakable object in the hay), the shear bolt will break, halting the power transfer and preventing damage.

- Slip Clutch: Some PTO shafts are equipped with a slip clutch, which performs a similar function. It allows the PTO to slip or disengage under heavy load, avoiding damage to the shaft or baler in the event of an overload.

-

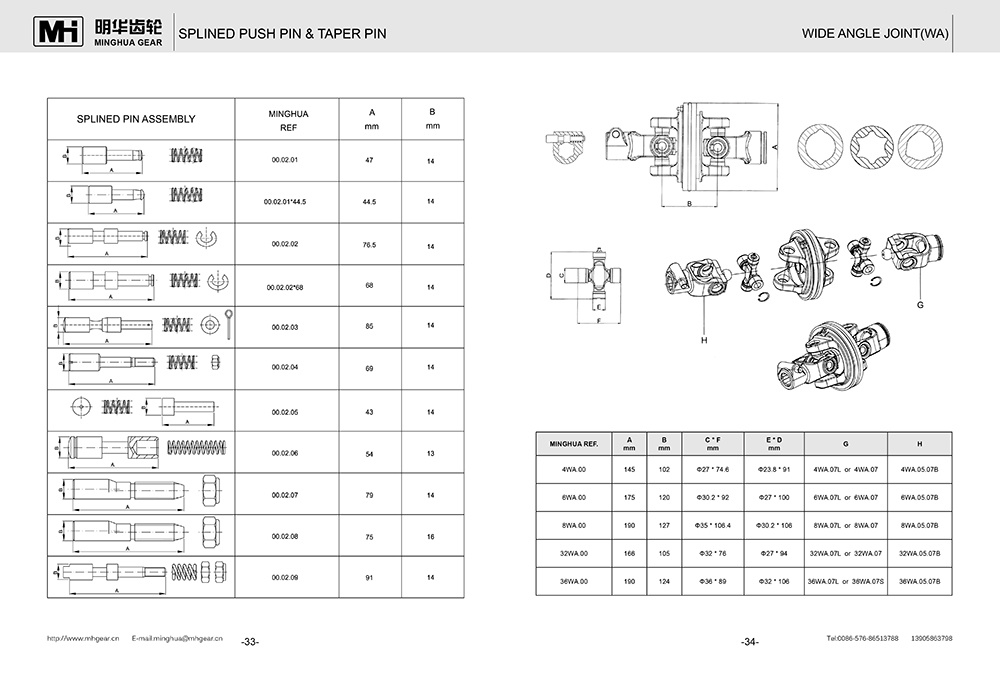

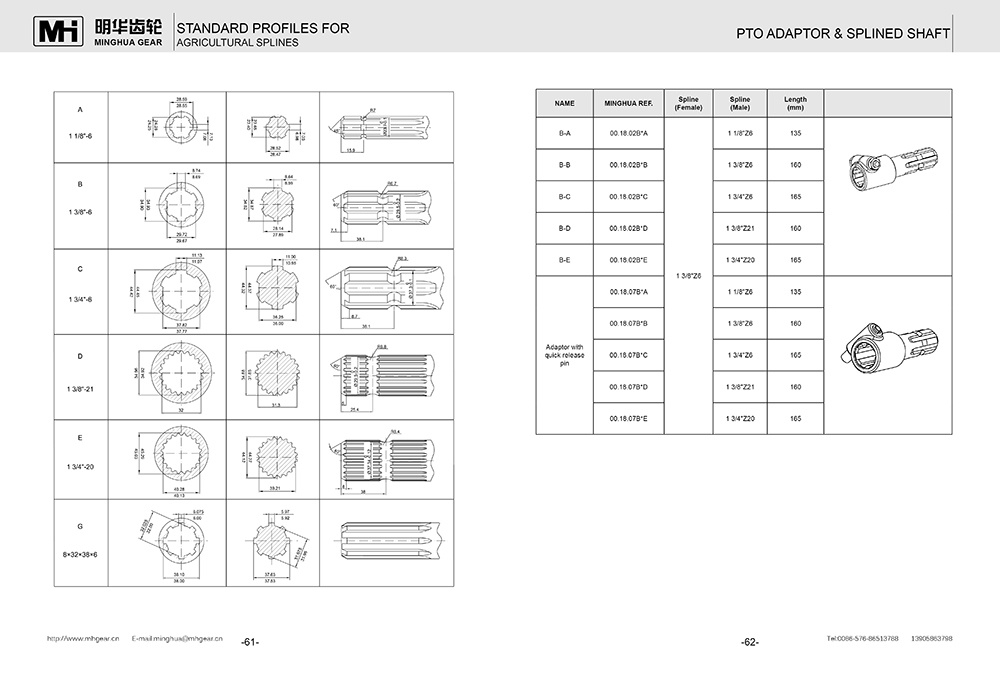

Spline Connection

- The connection between the PTO shaft and the tractor’s PTO output is typically a splined connection, ensuring a firm grip and efficient power transfer. Standard tractors have either a 540 RPM or 1000 RPM PTO spline.

Operation of PTO Shafts in Hay Balers

- Power Transfer: The tractor’s PTO drives the baler’s internal mechanisms, including the pickup reel (which gathers hay), the plunger (which compresses the hay into bales), and the wrapping or tying system.

- Variable Speed: Depending on the type of baler and the density of the hay, the operator may adjust the tractor’s RPMs, ensuring the baler operates at an optimal speed for creating uniform, well-compressed bales.

Safety and Maintenance Tips for PTO Shafts on Hay Balers

-

Regular Inspection: Check the PTO shaft for wear, cracks, or damage before each use. Ensure that the U-joints and yokes are properly lubricated and in good working condition.

-

Proper Length: Ensure the PTO shaft is the correct length for the tractor and baler combination. A shaft that is too long or too short can place excessive strain on the U-joints and other components.

-

Keep Safety Guards in Place: Always operate the baler with the PTO shaft safety guard in place to prevent accidental contact with the rotating shaft.

-

Lubrication: Regularly lubricate the U-joints and telescoping shaft to ensure smooth operation and to extend the life of the PTO shaft.

-

Shear Bolt or Slip Clutch Maintenance: Inspect the shear bolt and replace it if it has broken. If using a slip clutch, check it regularly to ensure it is properly adjusted and functioning.

-

Avoid Sharp Angles: Minimize sharp turns or tight angles between the tractor and baler during operation. Excessive misalignment can lead to U-joint failure or wear.

-

Engage PTO Slowly: When starting the baler, engage the PTO at a low RPM and gradually increase it to operating speed. This helps prevent sudden load on the PTO shaft and baler.

Applications:

Benefits of PTO Shafts in Hay Balers

-

Efficient Power Transfer: PTO shafts provide a reliable and consistent way to transfer power from the tractor to the baler, ensuring efficient operation.

-

Adaptability: With telescoping and wide-angle options, PTO shafts can accommodate various field conditions, such as uneven ground or tight turns, without compromising performance.

-

Safety Features: With shear bolts, slip clutches, and safety guards, PTO shafts are designed to protect both the equipment and the operator from damage or injury in case of a malfunction.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Part description

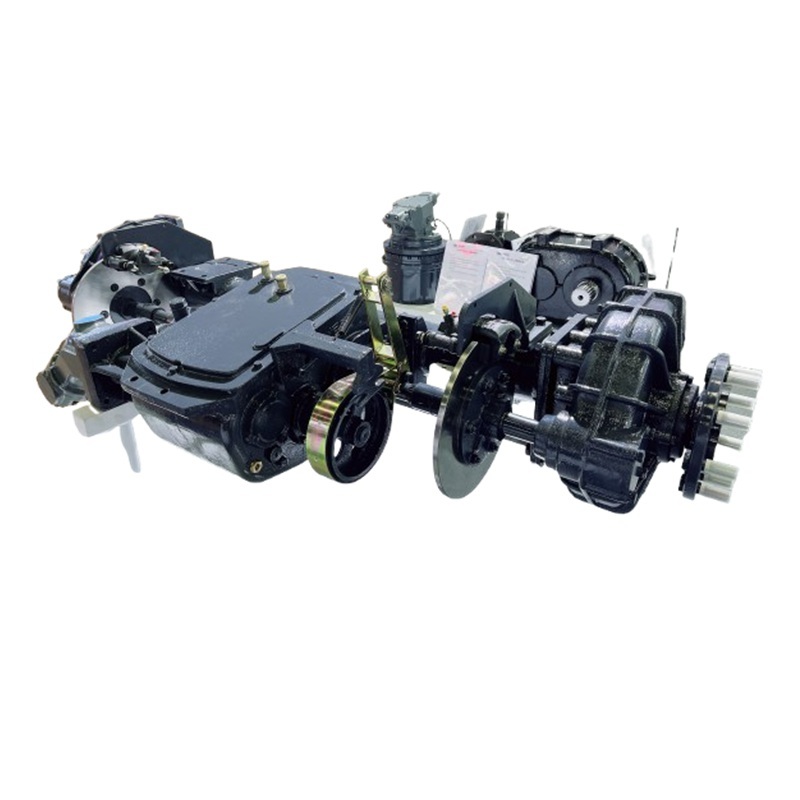

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

PTO Shaft for Hay Baler

Key words:

PTO shaft

Classification:

Product Details

PTO Shaft for Hay Baler

Minghua Gear made PTO shaft for a hay baler is a critical component that connects the tractor's Power Take-Off (PTO) to the baler, transmitting mechanical power from the tractor to the baler’s internal mechanisms. This power enables the baler to operate its various functions, such as gathering hay, compressing it into bales, and tying or wrapping the bales.

Types of PTO Shafts for Hay Balers

-

540 RPM PTO Shaft

- This type is common for most small to medium-sized balers and is typically used on tractors with a 540 RPM PTO system. It is designed for standard baling tasks such as creating small to medium-sized round or square bales.

-

1000 RPM PTO Shaft

- For larger or high-capacity hay balers, a 1000 RPM PTO shaft is used, which provides more power. This higher-speed shaft is typically found on larger tractors and is used for heavy-duty baling operations that involve high-volume or dense bales.

-

Wide-Angle PTO Shaft

- Some balers require a wide-angle PTO shaft, which allows for greater flexibility in movement and alignment. This type of shaft is useful when working in fields with tight turns or uneven terrain, providing more range of motion without causing excessive strain on the PTO components.

Key Components of a PTO Shaft for a Hay Baler

-

Telescoping Shaft

- The PTO shaft typically consists of two telescoping parts (inner and outer tubes) that allow for length adjustments as the tractor moves, ensuring constant power transmission even when working on uneven ground or during tight turns.

-

Universal Joints (U-Joints)

- Located at both ends of the PTO shaft, the U-joints allow the shaft to transmit rotational power while accommodating slight misalignments between the tractor and the baler. This flexibility is necessary for smooth operation, especially on uneven terrain.

-

Yokes

- The yokes are mounted on the ends of the PTO shaft to connect it to both the tractor’s PTO output shaft and the baler’s input shaft. The yokes, along with the U-joints, allow for rotational movement and power transfer.

-

Safety Guard

- The PTO shaft is usually enclosed by a protective guard or safety shield that helps prevent accidental contact with the spinning shaft. This is an important safety feature, as the rotating shaft poses a significant hazard during operation.

-

Shear Bolt or Slip Clutch

- Shear Bolt: A shear bolt is a safety feature that protects the PTO shaft, the tractor, and the baler from damage. If the baler encounters an obstruction (such as a large, unbreakable object in the hay), the shear bolt will break, halting the power transfer and preventing damage.

- Slip Clutch: Some PTO shafts are equipped with a slip clutch, which performs a similar function. It allows the PTO to slip or disengage under heavy load, avoiding damage to the shaft or baler in the event of an overload.

-

Spline Connection

- The connection between the PTO shaft and the tractor’s PTO output is typically a splined connection, ensuring a firm grip and efficient power transfer. Standard tractors have either a 540 RPM or 1000 RPM PTO spline.

Operation of PTO Shafts in Hay Balers

- Power Transfer: The tractor’s PTO drives the baler’s internal mechanisms, including the pickup reel (which gathers hay), the plunger (which compresses the hay into bales), and the wrapping or tying system.

- Variable Speed: Depending on the type of baler and the density of the hay, the operator may adjust the tractor’s RPMs, ensuring the baler operates at an optimal speed for creating uniform, well-compressed bales.

Safety and Maintenance Tips for PTO Shafts on Hay Balers

-

Regular Inspection: Check the PTO shaft for wear, cracks, or damage before each use. Ensure that the U-joints and yokes are properly lubricated and in good working condition.

-

Proper Length: Ensure the PTO shaft is the correct length for the tractor and baler combination. A shaft that is too long or too short can place excessive strain on the U-joints and other components.

-

Keep Safety Guards in Place: Always operate the baler with the PTO shaft safety guard in place to prevent accidental contact with the rotating shaft.

-

Lubrication: Regularly lubricate the U-joints and telescoping shaft to ensure smooth operation and to extend the life of the PTO shaft.

-

Shear Bolt or Slip Clutch Maintenance: Inspect the shear bolt and replace it if it has broken. If using a slip clutch, check it regularly to ensure it is properly adjusted and functioning.

-

Avoid Sharp Angles: Minimize sharp turns or tight angles between the tractor and baler during operation. Excessive misalignment can lead to U-joint failure or wear.

-

Engage PTO Slowly: When starting the baler, engage the PTO at a low RPM and gradually increase it to operating speed. This helps prevent sudden load on the PTO shaft and baler.

Applications:

Benefits of PTO Shafts in Hay Balers

-

Efficient Power Transfer: PTO shafts provide a reliable and consistent way to transfer power from the tractor to the baler, ensuring efficient operation.

-

Adaptability: With telescoping and wide-angle options, PTO shafts can accommodate various field conditions, such as uneven ground or tight turns, without compromising performance.

-

Safety Features: With shear bolts, slip clutches, and safety guards, PTO shafts are designed to protect both the equipment and the operator from damage or injury in case of a malfunction.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Part description

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.