Ring Gear for Cranes Swing Drives

Key words:

Gear ring

Classification:

Product Details

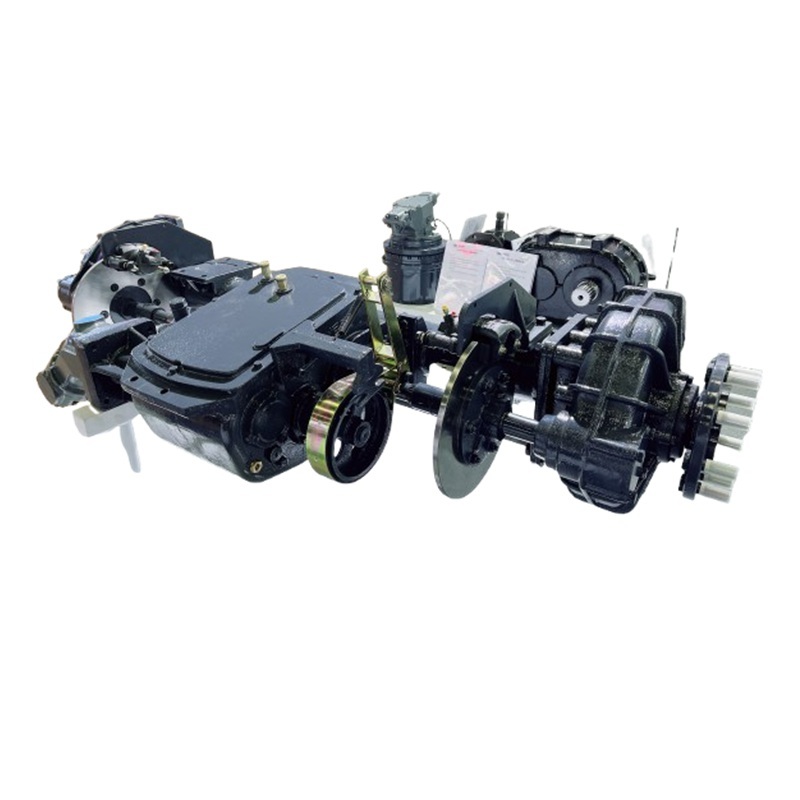

Ring Gear for Cranes Swing Drives

Ring gears, also known as internal gears or annular gears, play a crucial role in construction machinery, where they are used to transmit torque, often in high-load and high-torque environments. Their design and application are tailored to meet the demanding requirements of construction equipment, such as excavators, cranes, and other heavy-duty machines.

Key Applications of Ring Gears in Construction Machinery:

-

Slewing Drives:

- Function: Ring gears are integral to slewing drives, which enable the rotation of the upper structure (superstructure) of machinery like cranes and excavators relative to the undercarriage. This rotational movement is essential for operations such as lifting and moving materials.

- Design: The ring gear in a slewing drive typically meshes with a pinion gear connected to a motor, allowing controlled and powerful rotation. The gear design must accommodate high radial and axial loads.

-

Planetary Gear Systems:

- Function: In planetary gear systems, the ring gear serves as the outer gear that encircles the planet gears. This setup is commonly used in the gearboxes of construction machinery to achieve high torque in a compact design.

- Design: The internal teeth of the ring gear engage with the planet gears, which in turn mesh with a central sun gear. This configuration is particularly effective for applications requiring a high torque-to-weight ratio.

-

Track Drives:

- Function: Some construction machines, such as tracked vehicles (e.g., bulldozers), use ring gears in their track drive systems. These gears help convert rotational power into the movement needed to propel the vehicle.

- Design: The ring gear is usually part of the final drive mechanism, providing the necessary reduction in speed and increase in torque to drive the tracks.

Minghua made Ring Gear for Cranes Swing Drives features.

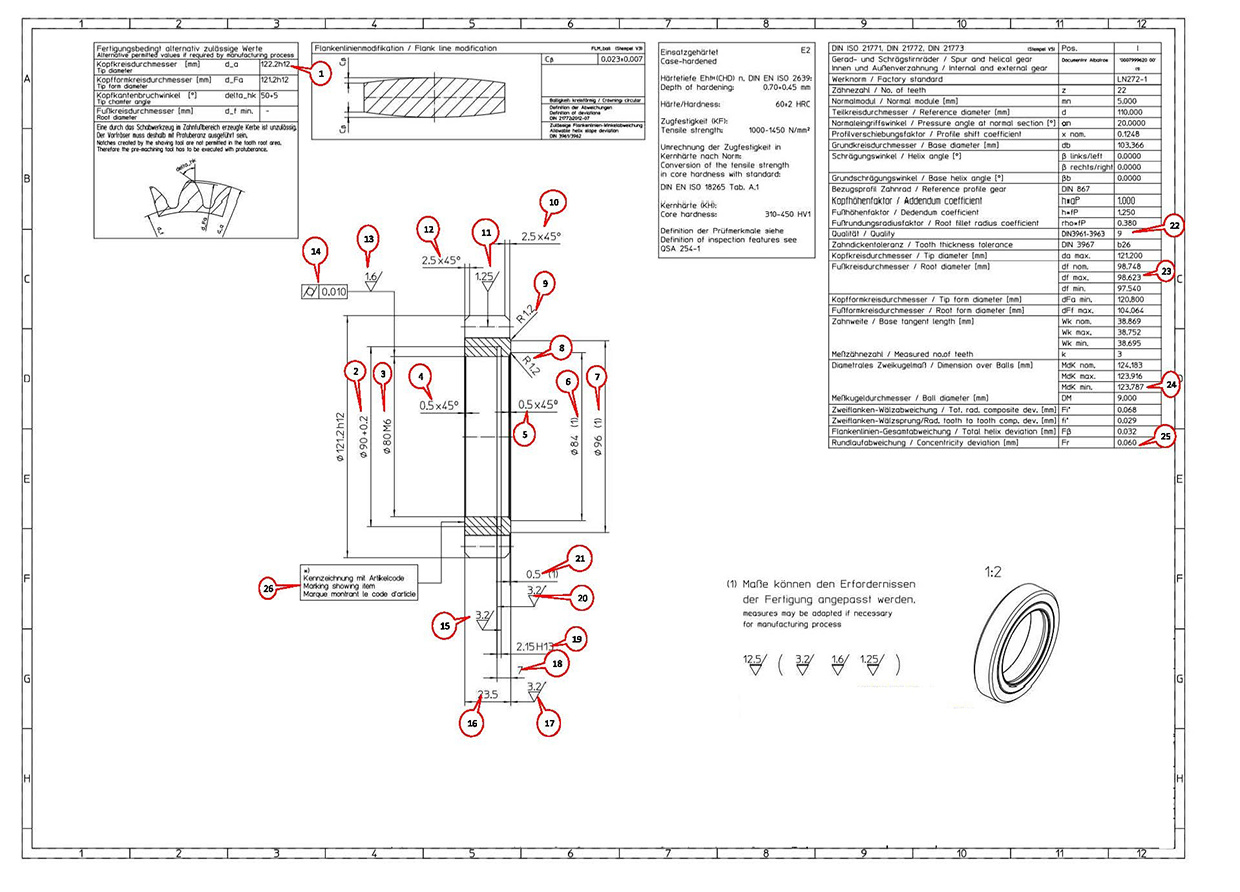

Roll forging, quenching&tempering, rough turning, gear shaping, heat treatment, finishing turning, teeth grinding, inspection.

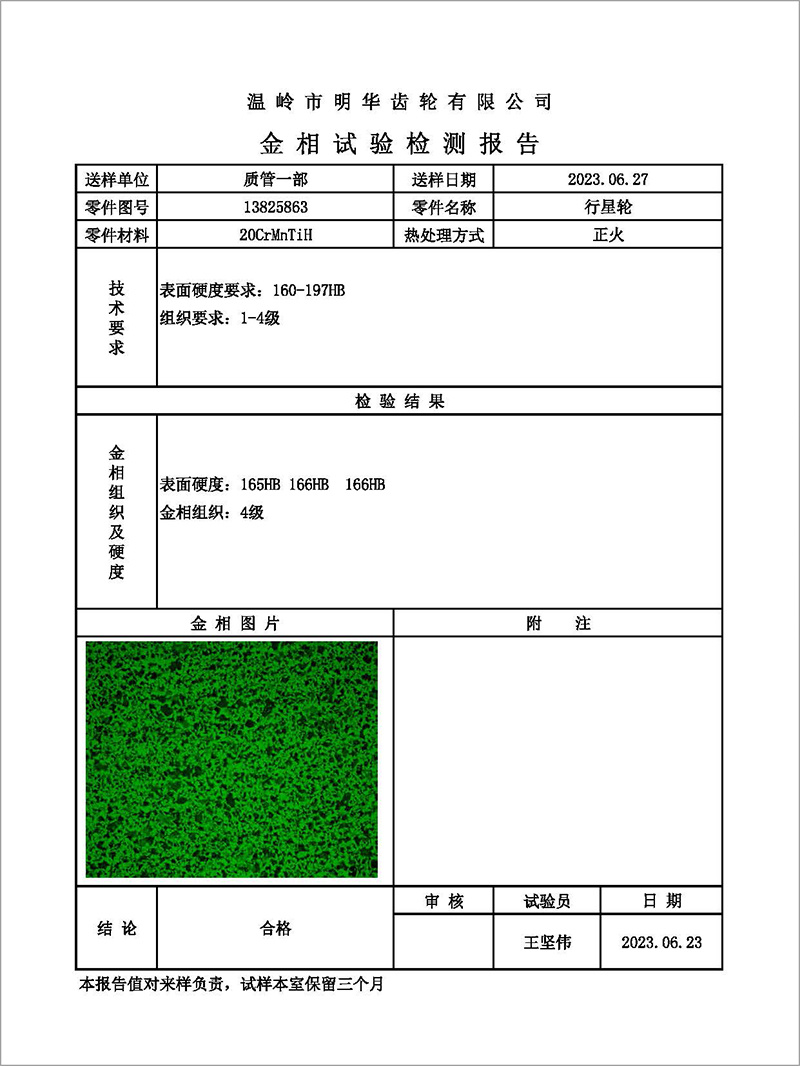

Gear shafts in transmission machinery are usually made by 45 steel in high-quality carbon steel, 40Cr, 42CrMo, 20CrMnTi in alloy steel, 20MnCr5, 20CrMoH,16MnCr5, 18CrNiMo etc.

Heat treatment process available: normalizing, tempering, carburizing, quenching, high frequency, nitridation Generally, it meets the strength requirements of the material, and with excellent wear resistance.

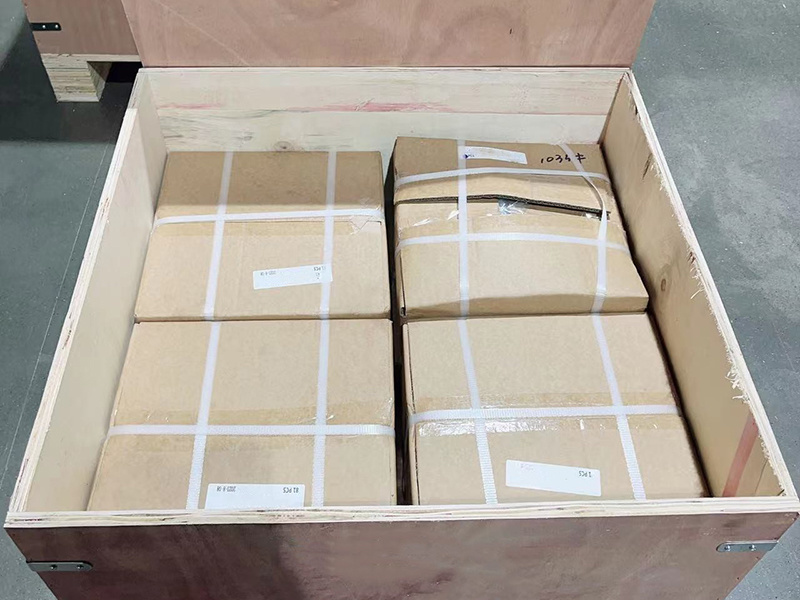

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

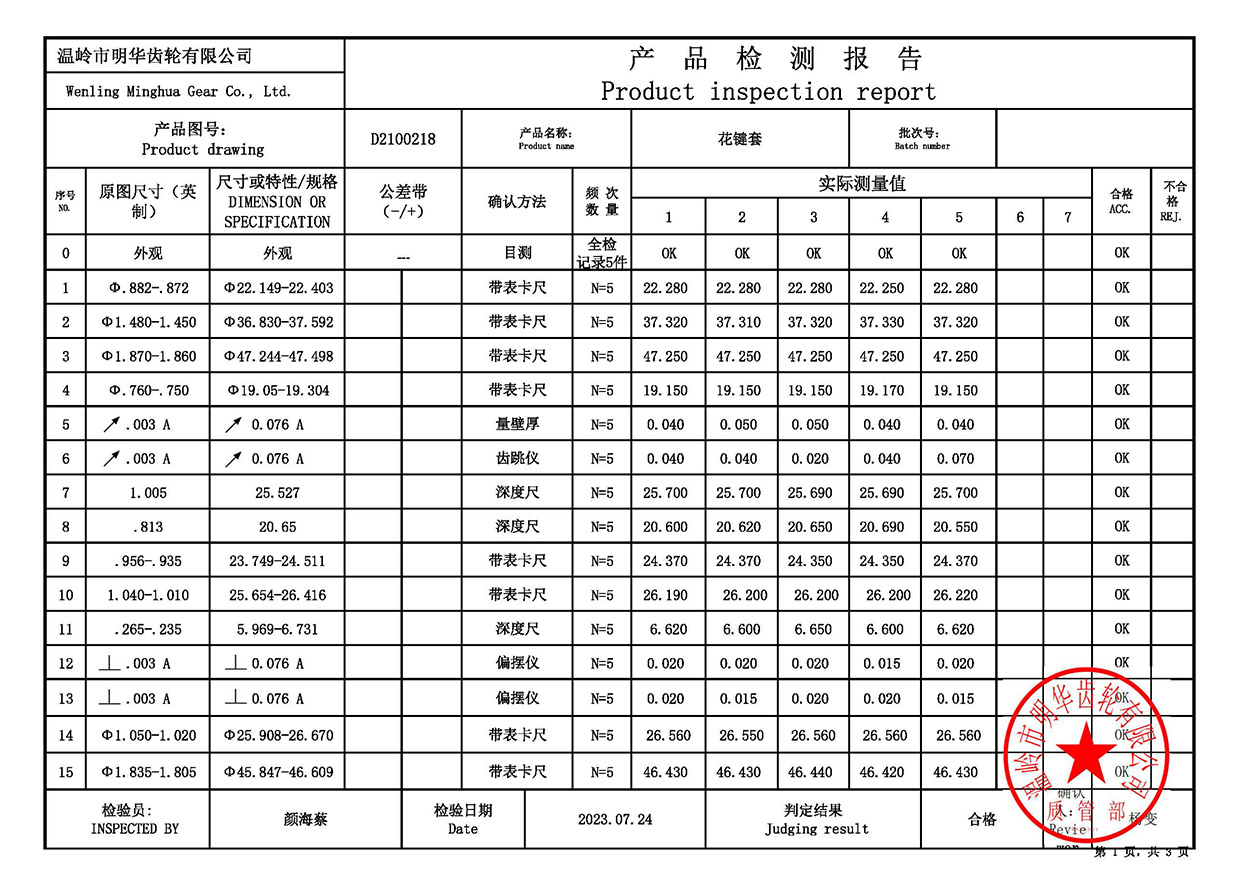

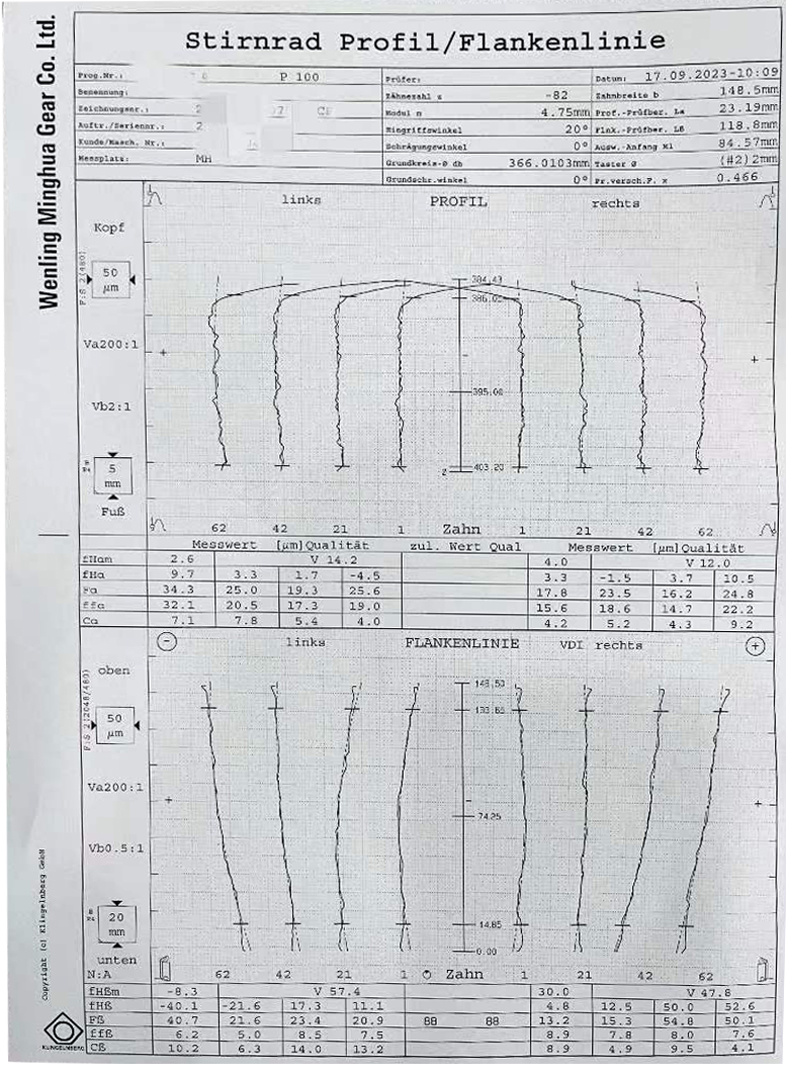

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Quality Control

Before every shipping ,we will do following testing and provide whole quality reports for these gears:

1).Bubble drawing

2).Dimension measurement report

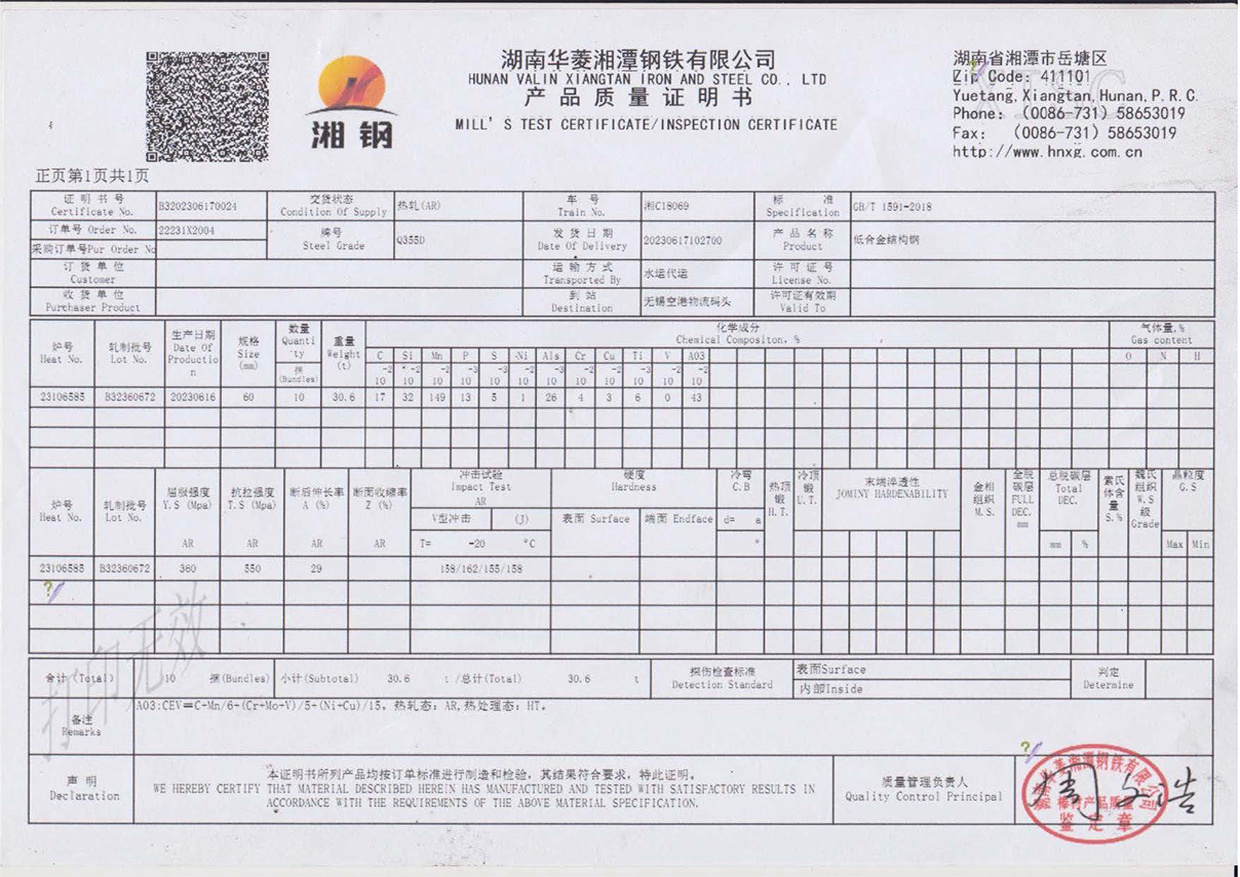

3).Material certification report

4).Heat treatment testing report

5).Accuracy measurement report

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Ring Gear for Cranes Swing Drives

Key words:

Gear ring

Classification:

Product Details

Ring Gear for Cranes Swing Drives

Ring gears, also known as internal gears or annular gears, play a crucial role in construction machinery, where they are used to transmit torque, often in high-load and high-torque environments. Their design and application are tailored to meet the demanding requirements of construction equipment, such as excavators, cranes, and other heavy-duty machines.

Key Applications of Ring Gears in Construction Machinery:

-

Slewing Drives:

- Function: Ring gears are integral to slewing drives, which enable the rotation of the upper structure (superstructure) of machinery like cranes and excavators relative to the undercarriage. This rotational movement is essential for operations such as lifting and moving materials.

- Design: The ring gear in a slewing drive typically meshes with a pinion gear connected to a motor, allowing controlled and powerful rotation. The gear design must accommodate high radial and axial loads.

-

Planetary Gear Systems:

- Function: In planetary gear systems, the ring gear serves as the outer gear that encircles the planet gears. This setup is commonly used in the gearboxes of construction machinery to achieve high torque in a compact design.

- Design: The internal teeth of the ring gear engage with the planet gears, which in turn mesh with a central sun gear. This configuration is particularly effective for applications requiring a high torque-to-weight ratio.

-

Track Drives:

- Function: Some construction machines, such as tracked vehicles (e.g., bulldozers), use ring gears in their track drive systems. These gears help convert rotational power into the movement needed to propel the vehicle.

- Design: The ring gear is usually part of the final drive mechanism, providing the necessary reduction in speed and increase in torque to drive the tracks.

Minghua made Ring Gear for Cranes Swing Drives features.

Roll forging, quenching&tempering, rough turning, gear shaping, heat treatment, finishing turning, teeth grinding, inspection.

Gear shafts in transmission machinery are usually made by 45 steel in high-quality carbon steel, 40Cr, 42CrMo, 20CrMnTi in alloy steel, 20MnCr5, 20CrMoH,16MnCr5, 18CrNiMo etc.

Heat treatment process available: normalizing, tempering, carburizing, quenching, high frequency, nitridation Generally, it meets the strength requirements of the material, and with excellent wear resistance.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Quality Control

Before every shipping ,we will do following testing and provide whole quality reports for these gears:

1).Bubble drawing

2).Dimension measurement report

3).Material certification report

4).Heat treatment testing report

5).Accuracy measurement report

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.