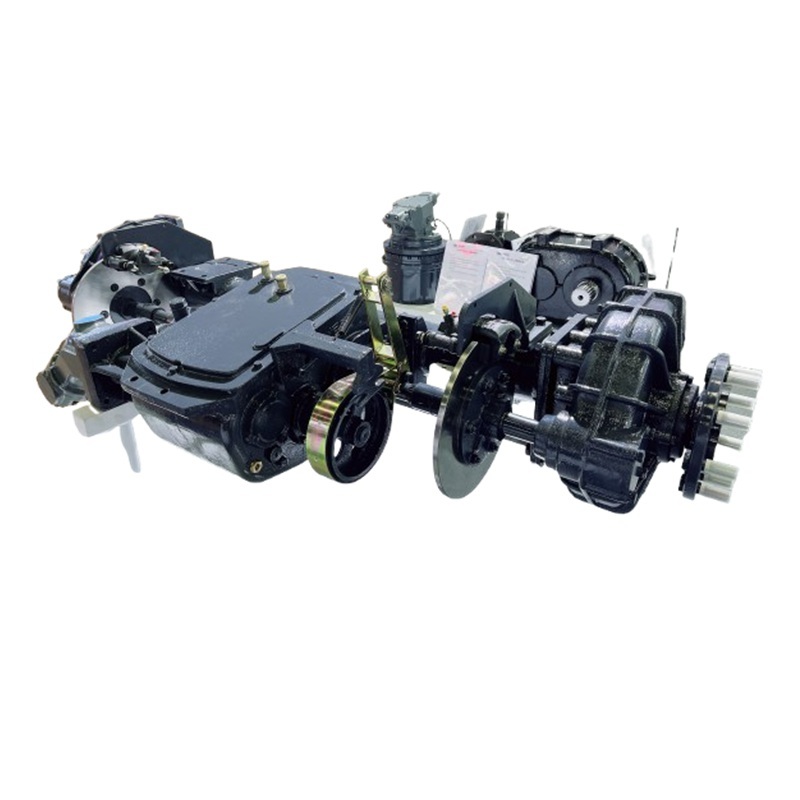

Excavator Travel Device Hydraulic Planetary Gearbox

Key words:

Planetary reducer

Classification:

Product Details

Special Features:

1. Compact, space-saving, two or three stage planetary gear design

2. Firm brand high performance bearings

3. Simple mounting, easy oil change

4. Highly precise gears, low-noise running

Application Conditions:

The gearboxes have been designed for use at ambient temperatures ranging between -20°Ê and + 40°Ê.

Environmental influence such as salt water, salty air, sand, dust, overpressure, heavy vibrations, extreme shocks and ambient temperature, aggressive media and the like will impede the function of the product.

To enable a safe design of the winch drive such conditions must be reported to the factory.

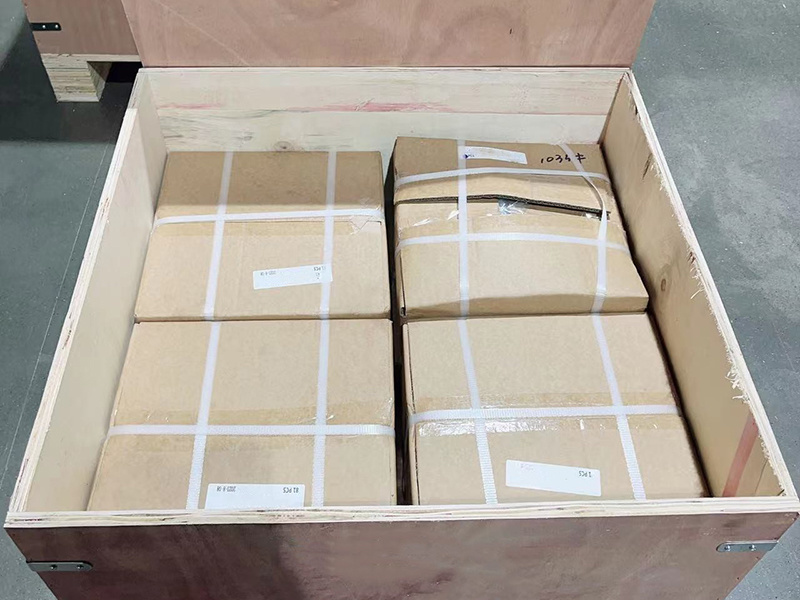

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Excavator Travel Device Hydraulic Planetary Gearbox

Key words:

Planetary reducer

Classification:

Product Details

Special Features:

1. Compact, space-saving, two or three stage planetary gear design

2. Firm brand high performance bearings

3. Simple mounting, easy oil change

4. Highly precise gears, low-noise running

Application Conditions:

The gearboxes have been designed for use at ambient temperatures ranging between -20°Ê and + 40°Ê.

Environmental influence such as salt water, salty air, sand, dust, overpressure, heavy vibrations, extreme shocks and ambient temperature, aggressive media and the like will impede the function of the product.

To enable a safe design of the winch drive such conditions must be reported to the factory.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.