Pump Motor Cover

Key words:

Product Center

Oil pump housing

Classification:

Product Details

Casting, quenching, rough turning, finishing turning, bore drilling, tempering, inspection.

Pump housing used in hydraulic machinery are usually made by QT350, QT400, QT600, QT800 etc.

Heat treatment process available: quenching, tempering Generally, it meets the strength requirements of the material, and with excellent wear resistance.

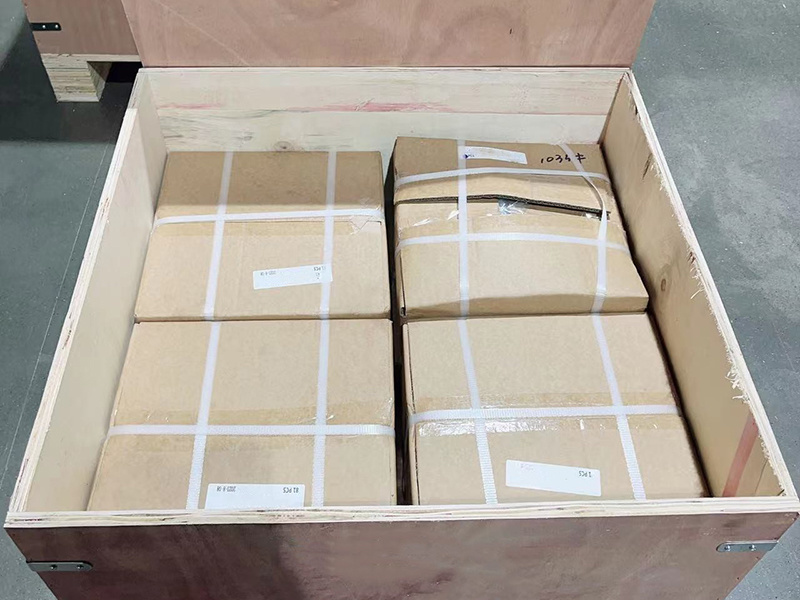

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

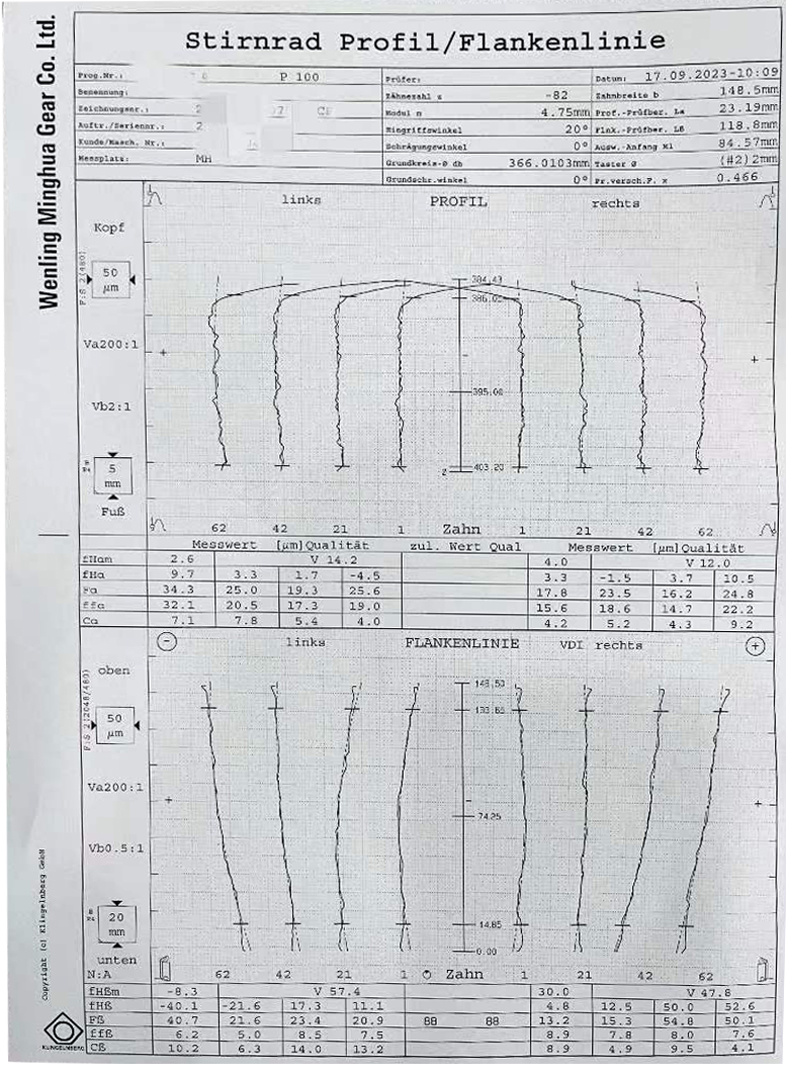

Full process inspection and testing.

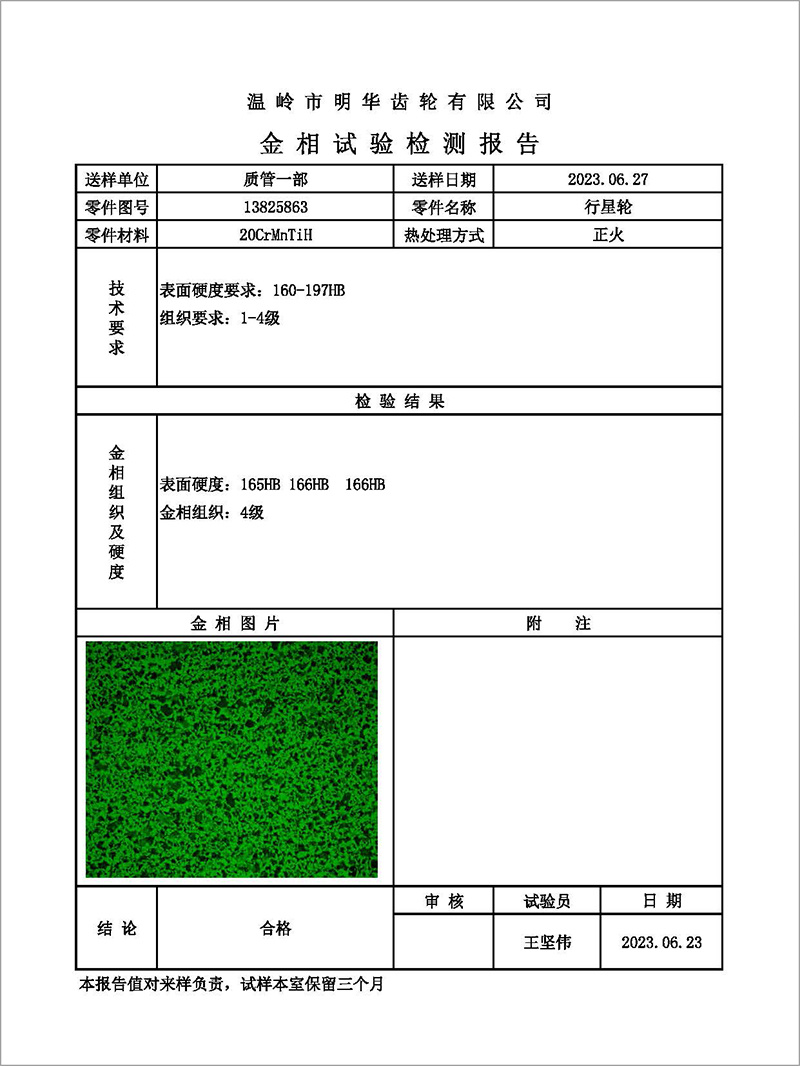

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Quality Control

Before every shipping ,we will do following testing and provide whole quality reports for these gears:

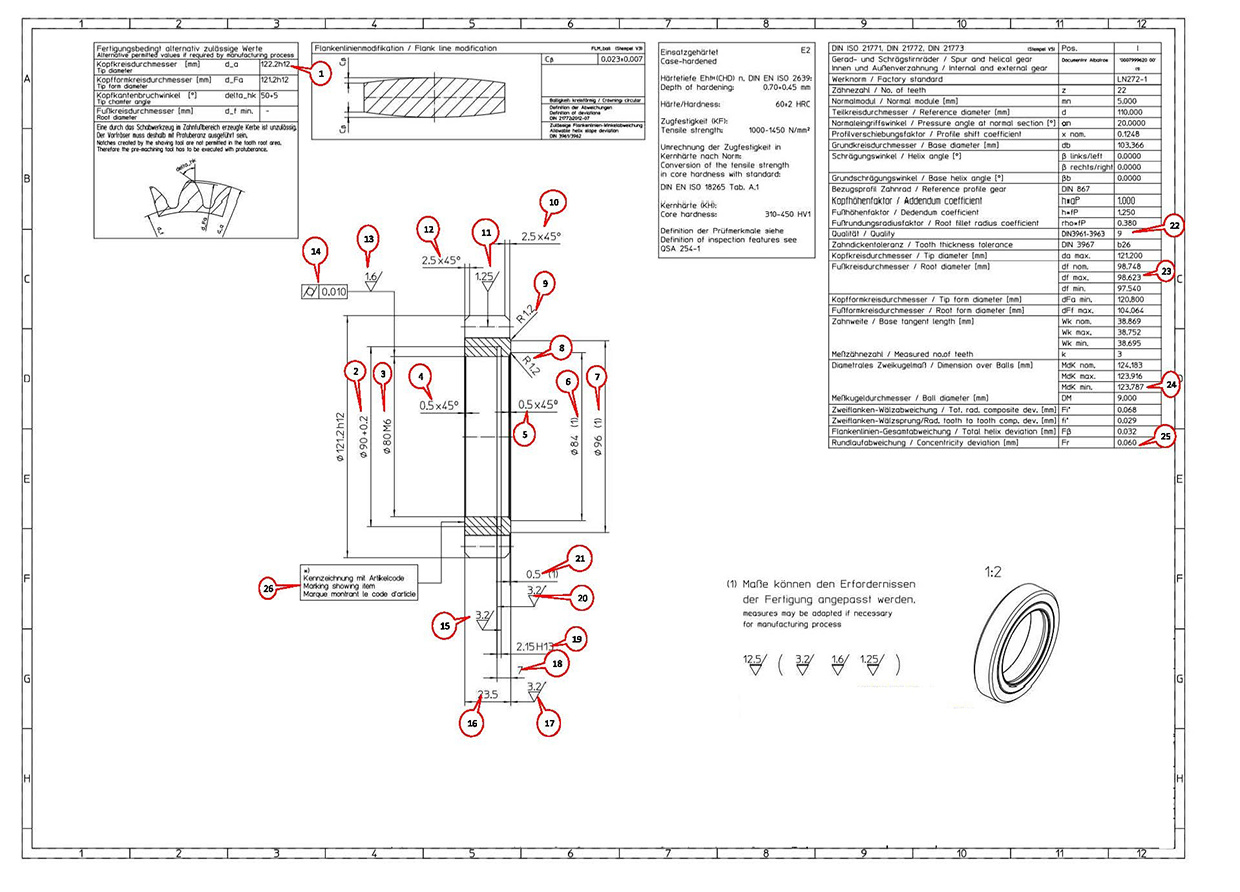

1).Bubble drawing

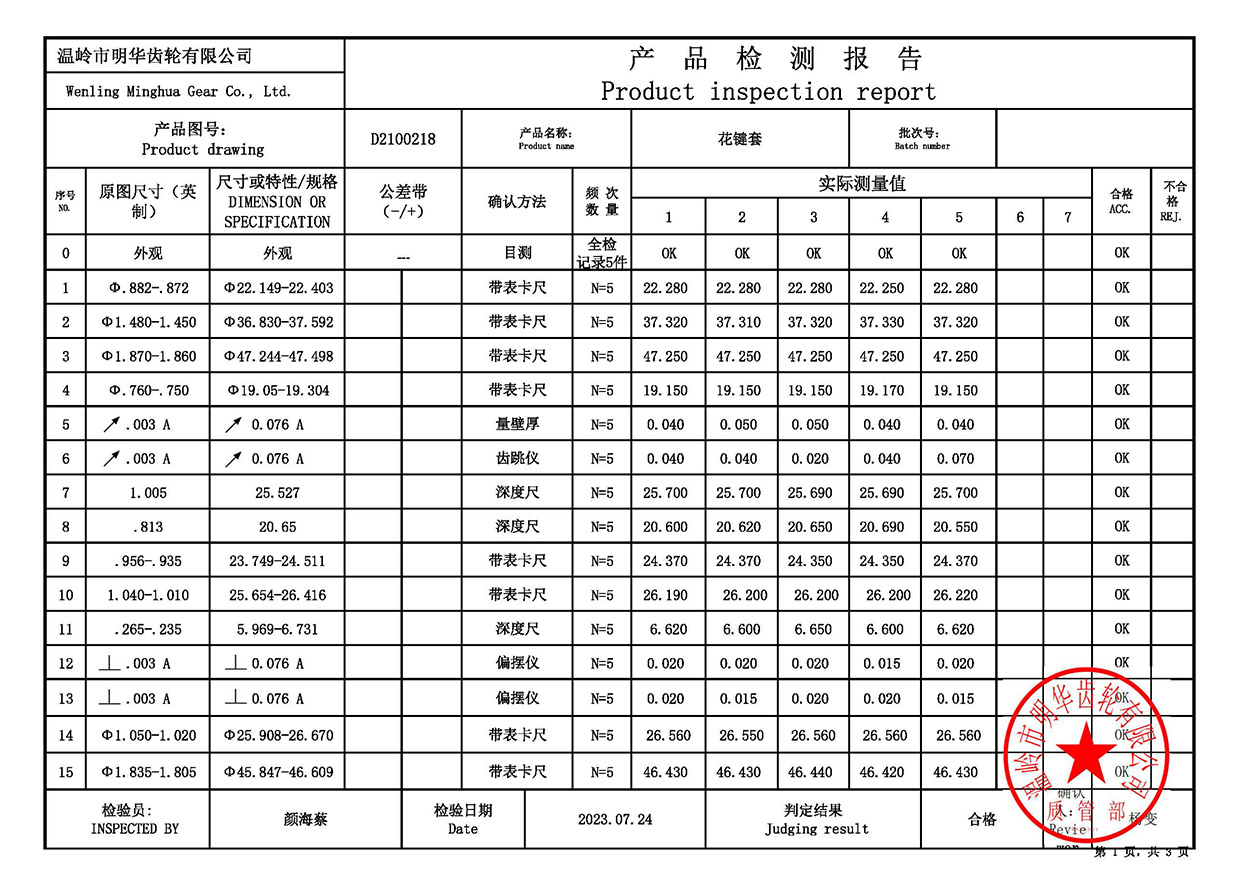

2).Dimension measurement report

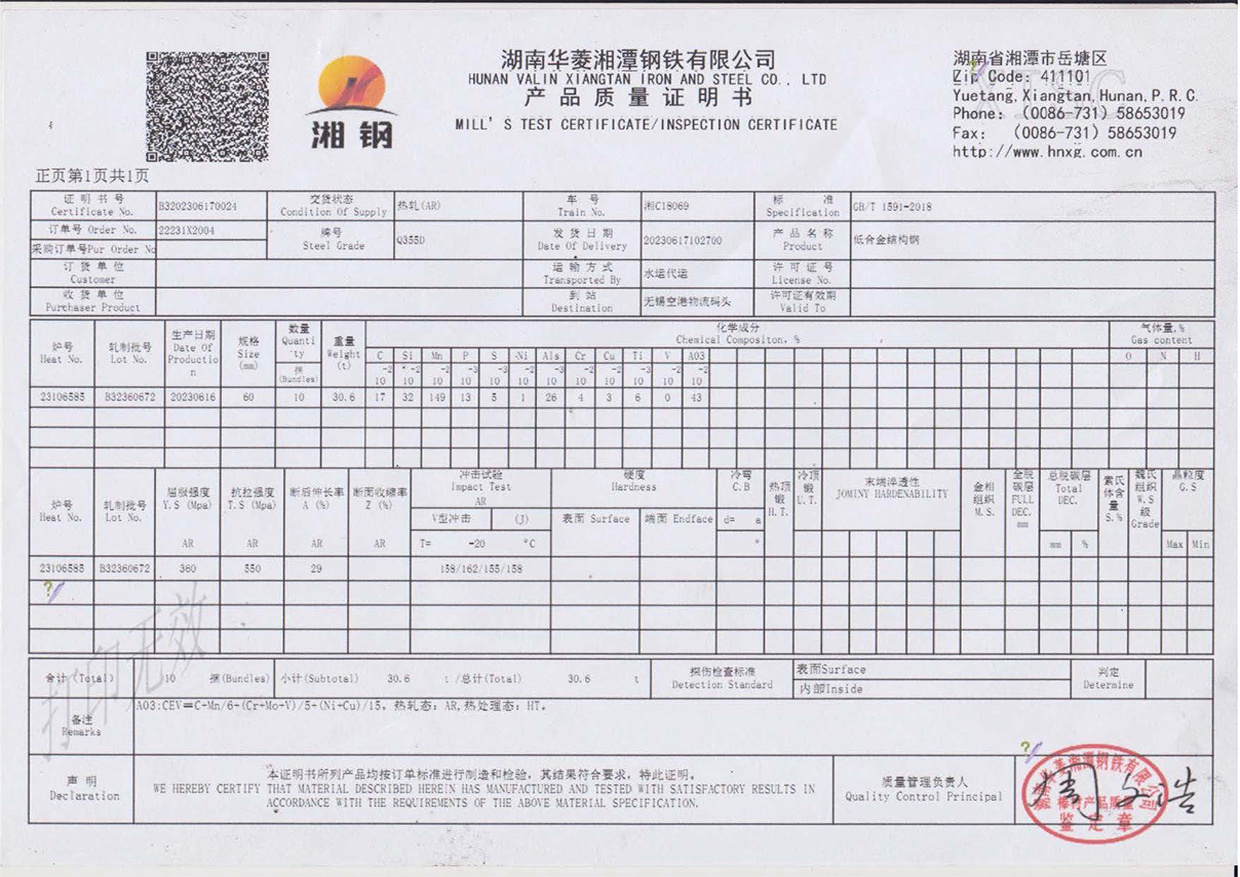

3).Material certification report

4).Heat treatment testing report

5).Accuracy measurement report

Production Strength

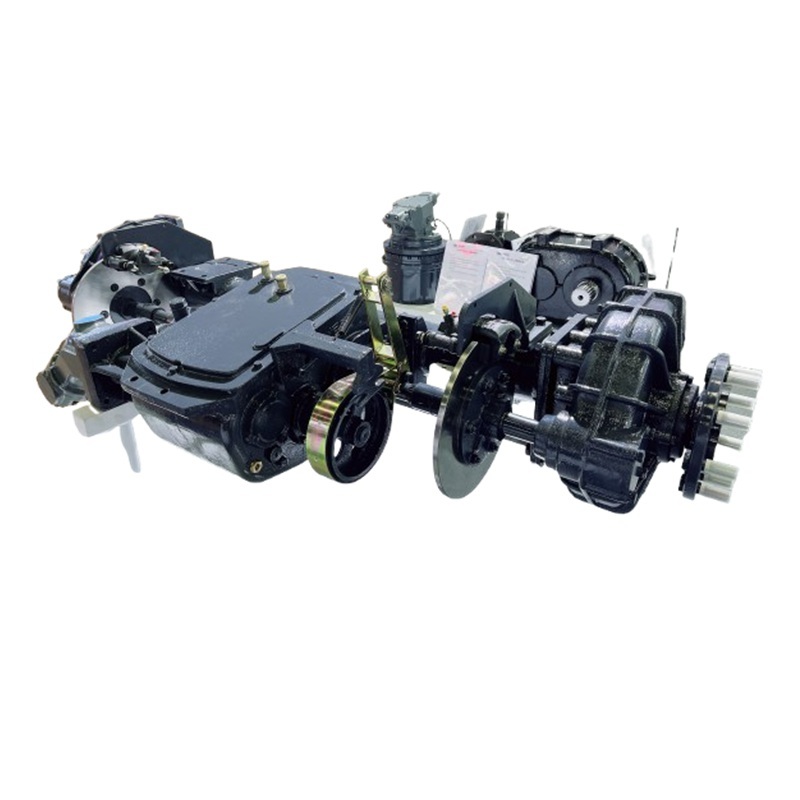

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Pump Motor Cover

Key words:

Product Center

Oil pump housing

Classification:

Product Details

Casting, quenching, rough turning, finishing turning, bore drilling, tempering, inspection.

Pump housing used in hydraulic machinery are usually made by QT350, QT400, QT600, QT800 etc.

Heat treatment process available: quenching, tempering Generally, it meets the strength requirements of the material, and with excellent wear resistance.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Quality Control

Before every shipping ,we will do following testing and provide whole quality reports for these gears:

1).Bubble drawing

2).Dimension measurement report

3).Material certification report

4).Heat treatment testing report

5).Accuracy measurement report

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.