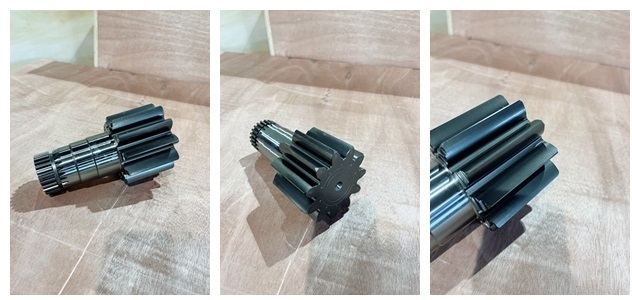

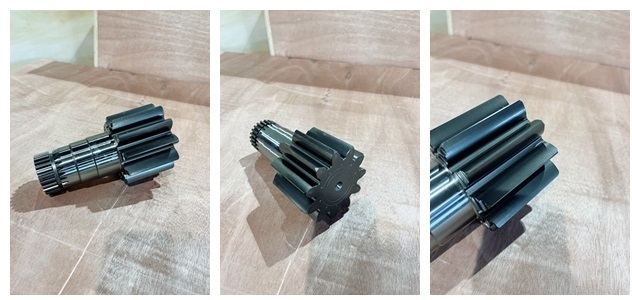

Spur Gear Shaft for Excavator Construction Machinery

Key words:

Excavator gear shaft

Classification:

Product Details

Spur Gear Shaft for Excavator Construction Machinery

Using a spur gear shaft in an excavator involves applying principles similar to those used in robot arms, but with a focus on heavy-duty performance, durability, and the ability to handle significant loads and stresses. Excavators require robust and reliable components due to the demanding nature of their operations.

Spur gears in excavators must be capable of handling high loads, including the stresses associated with digging, lifting, and moving heavy materials. The gear and shaft must be designed to distribute these loads effectively to prevent failure.

- High-Strength Steel: Commonly used for spur gears in excavators due to its excellent strength and wear resistance. Hardened steel gears can withstand the tough conditions and high forces experienced in excavation.

- Surface Treatment: Treatments such as carburizing, nitriding, or induction hardening are often applied to increase surface hardness and improve wear resistance.

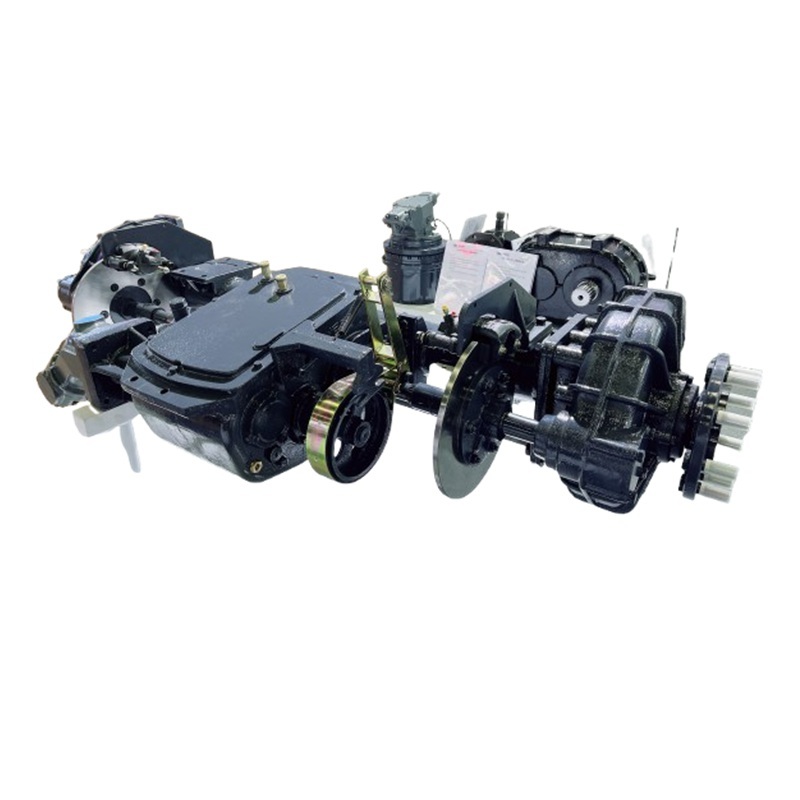

Applications of Spur Gear Shafts in Excavators:

-

Swing Drive Systems:

- Spur gears are used in the swing drive mechanism of an excavator, which controls the rotation of the excavator’s upper structure. The gears must handle the forces associated with stopping, starting, and maintaining the rotational movement under heavy loads.

-

Track Drive Systems:

- In some excavators, spur gears are used in the track drive system, converting motor torque into the force needed to move the machine.

-

Boom and Arm Actuators:

- Spur gear shafts can be part of the actuating mechanisms for the boom, arm, and bucket, controlling their movement and positioning during operation.

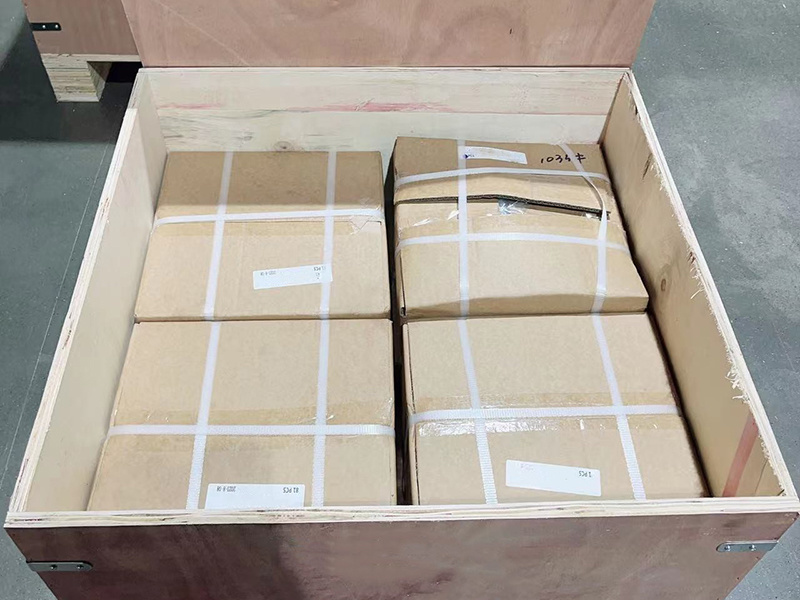

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

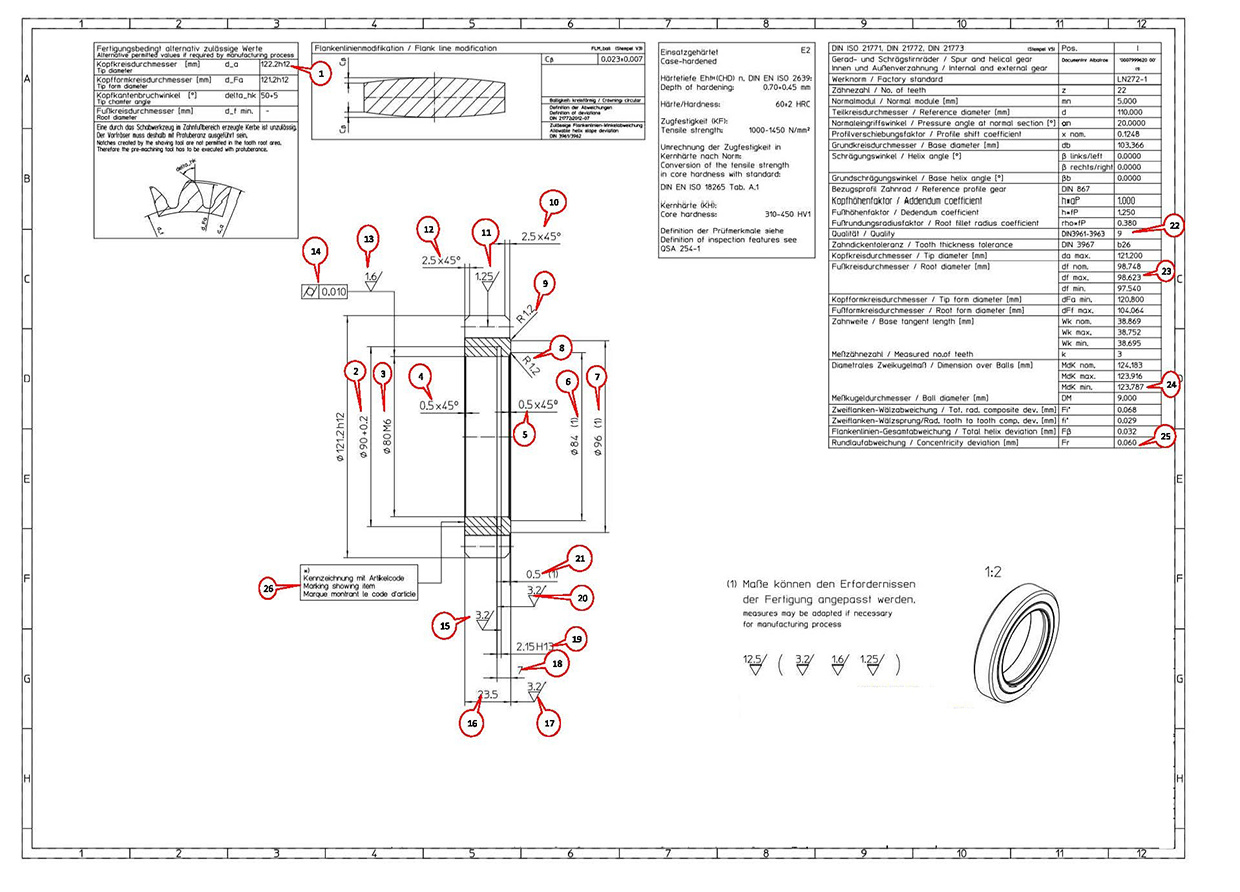

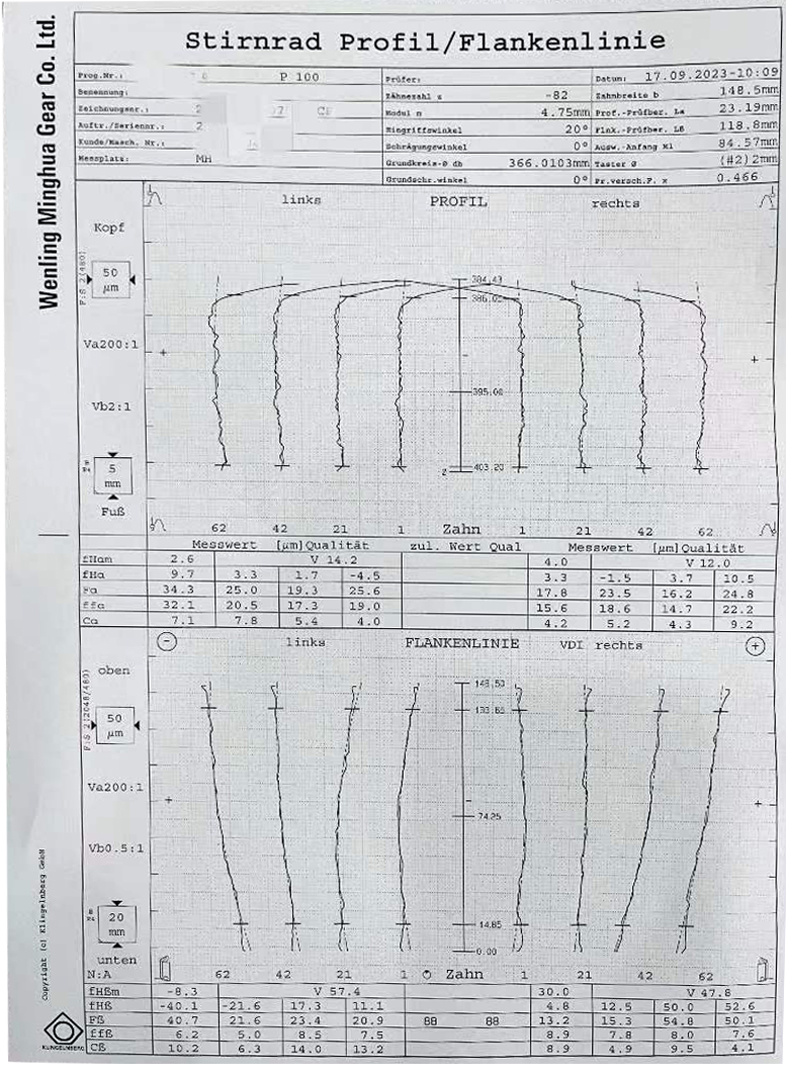

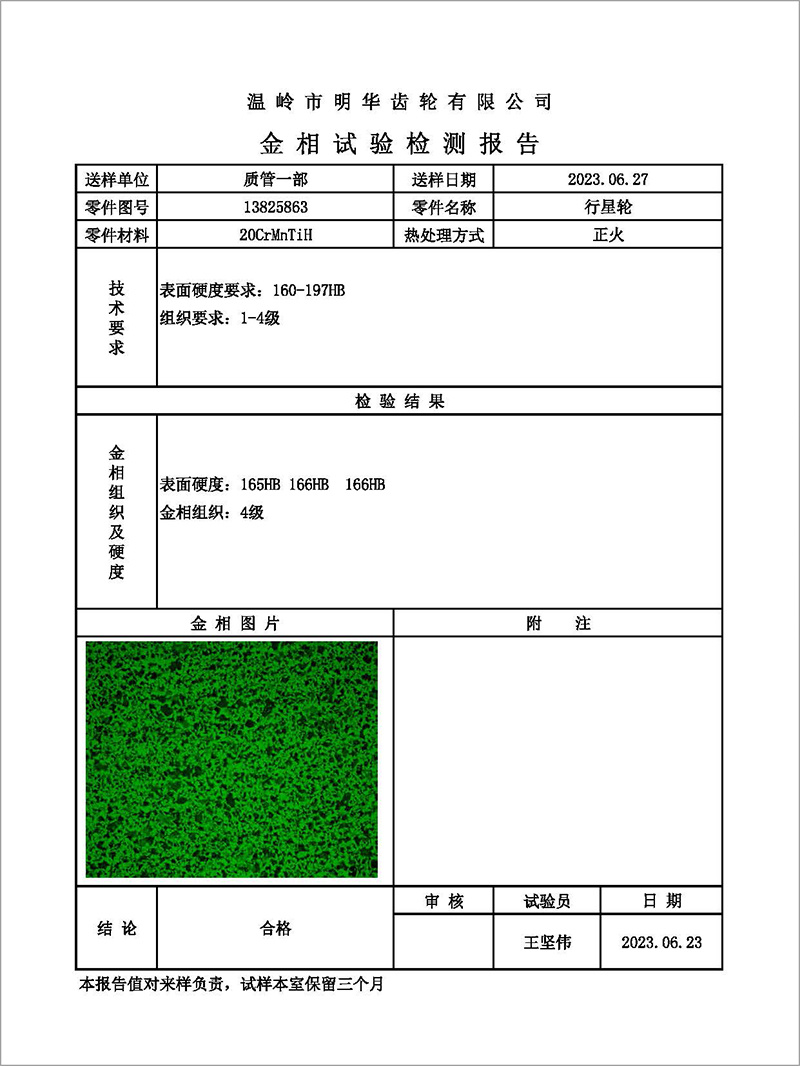

Testing Equipment

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

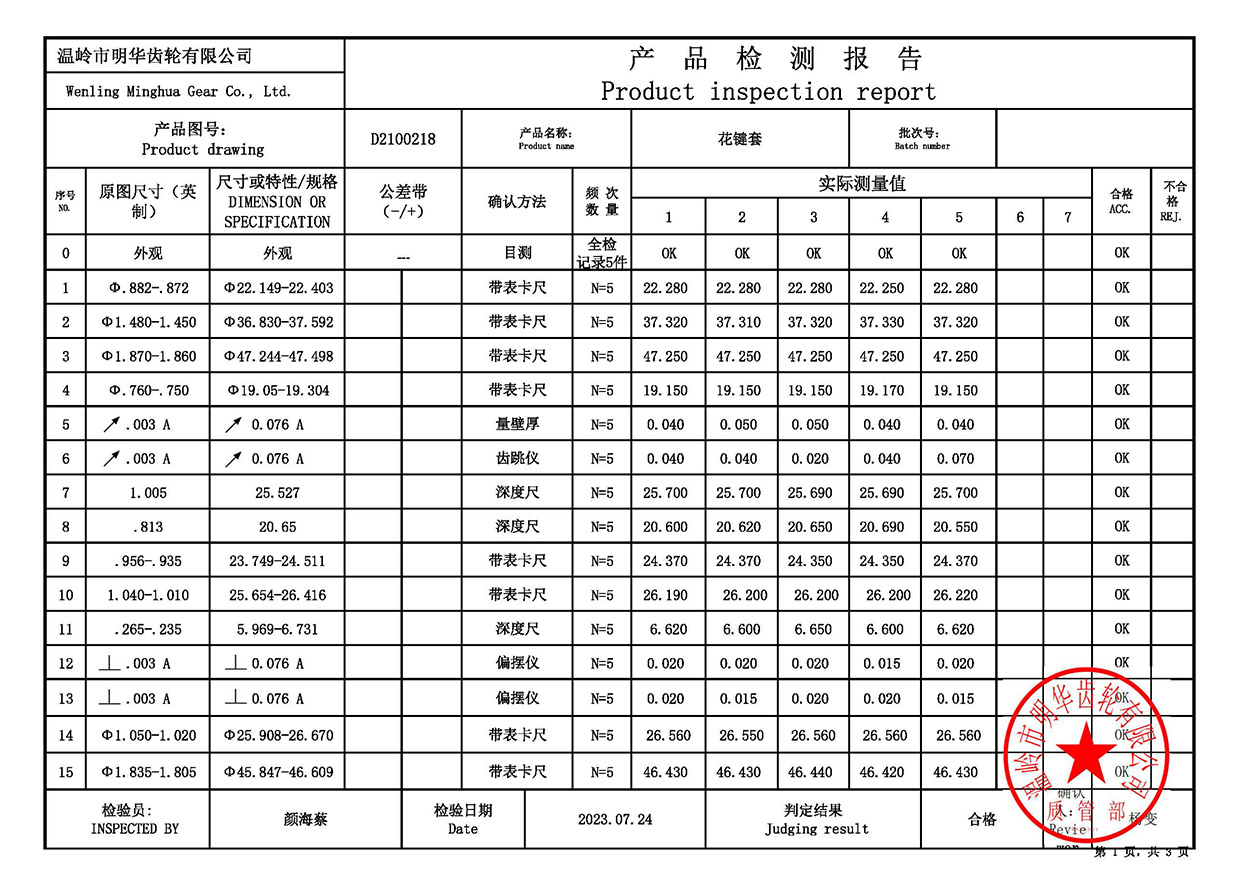

Quality Control

Before every shipping ,we will do following testing and provide whole quality reports for these gears:

1).Bubble drawing

2).Dimension measurement report

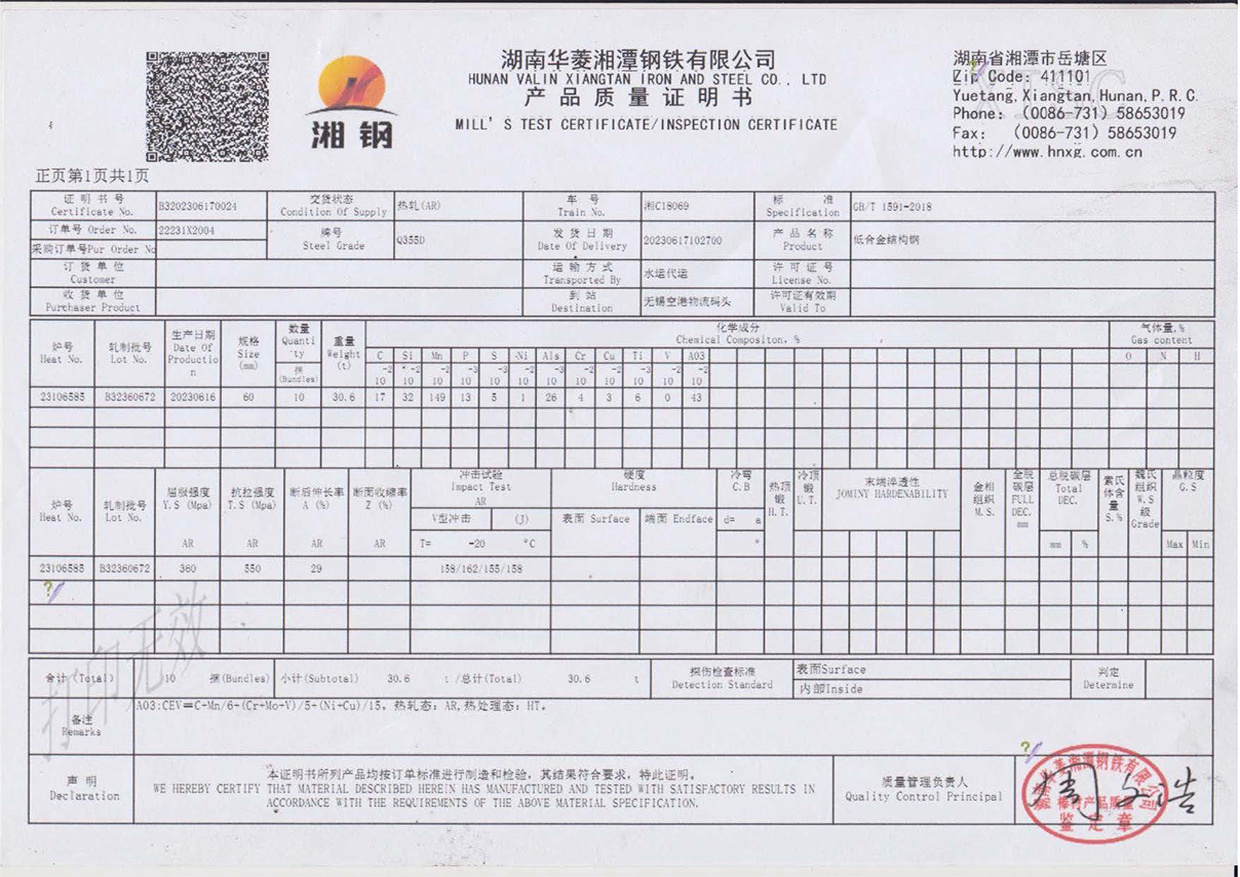

3).Material certification report

4).Heat treatment testing report

5).Accuracy measurement report

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Spur Gear Shaft for Excavator Construction Machinery

Key words:

Excavator gear shaft

Classification:

Product Details

Spur Gear Shaft for Excavator Construction Machinery

Using a spur gear shaft in an excavator involves applying principles similar to those used in robot arms, but with a focus on heavy-duty performance, durability, and the ability to handle significant loads and stresses. Excavators require robust and reliable components due to the demanding nature of their operations.

Spur gears in excavators must be capable of handling high loads, including the stresses associated with digging, lifting, and moving heavy materials. The gear and shaft must be designed to distribute these loads effectively to prevent failure.

- High-Strength Steel: Commonly used for spur gears in excavators due to its excellent strength and wear resistance. Hardened steel gears can withstand the tough conditions and high forces experienced in excavation.

- Surface Treatment: Treatments such as carburizing, nitriding, or induction hardening are often applied to increase surface hardness and improve wear resistance.

Applications of Spur Gear Shafts in Excavators:

-

Swing Drive Systems:

- Spur gears are used in the swing drive mechanism of an excavator, which controls the rotation of the excavator’s upper structure. The gears must handle the forces associated with stopping, starting, and maintaining the rotational movement under heavy loads.

-

Track Drive Systems:

- In some excavators, spur gears are used in the track drive system, converting motor torque into the force needed to move the machine.

-

Boom and Arm Actuators:

- Spur gear shafts can be part of the actuating mechanisms for the boom, arm, and bucket, controlling their movement and positioning during operation.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Quality Control

Before every shipping ,we will do following testing and provide whole quality reports for these gears:

1).Bubble drawing

2).Dimension measurement report

3).Material certification report

4).Heat treatment testing report

5).Accuracy measurement report

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.