Helical Gear for New Energy Passenger Vehicle Drive

Key words:

Heavy duty truck gear shaft

Classification:

Product Details

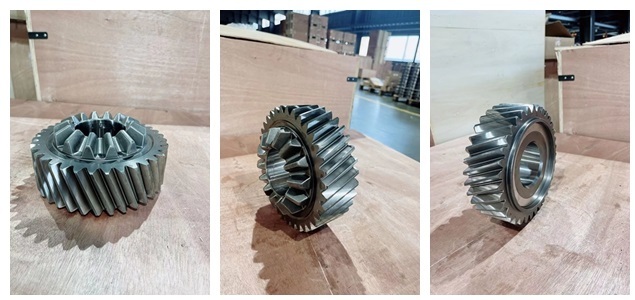

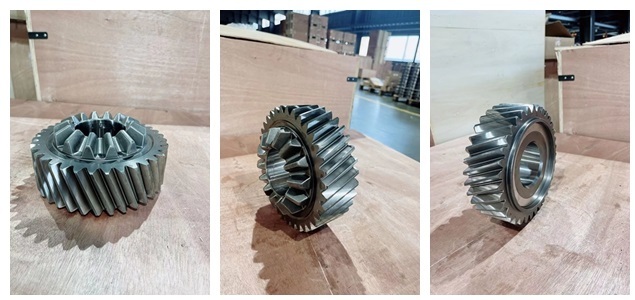

Helical Gear for New Energy Passenger Vehicle Drive

Helical gears are increasingly important in the drive systems of new energy passenger vehicles, such as electric vehicles (EVs) and hybrid vehicles. These gears are favored for their efficiency, quiet operation, and ability to handle high loads, which are crucial for the performance and comfort of modern vehicles.

-

Smooth and Quiet Operation:

- Helical gears have angled teeth, which engage gradually rather than all at once. This results in smoother transmission of power and significantly reduces noise and vibration. For electric vehicles, where the absence of an internal combustion engine makes gear noise more noticeable, this is a critical advantage.

-

High Load Capacity:

- The design of helical gears allows multiple teeth to be in contact simultaneously, which distributes the load more evenly across the gear. This increases the gear's load-carrying capacity, making it suitable for the high torque demands of electric vehicle drivetrains.

Minghua gear made Helical Gear for New Energy Passenger Vehicle Drive.

Precision forging, quenching&tempering, rough turning, hobbing, heat treatment, finishing turning, teeth grinding, inspection.

Gear shafts material usually use 42CrMoS4, 20MnCr5, 20CrMoH,16MnCr5, 18CrNiMo7-6 etc.

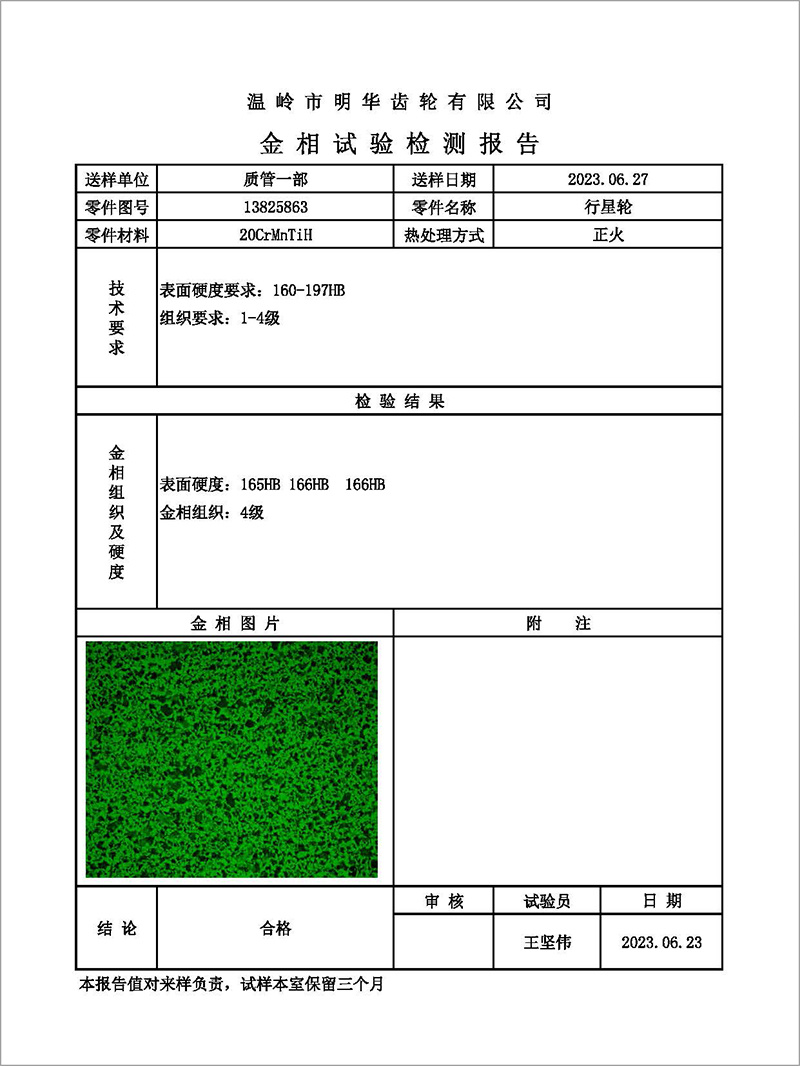

Heat treatment process available: normalizing, tempering, carburizing, quenching, high frequency, nitridation Generally, it meets the strength requirements of the material, and with excellent wear resistance.

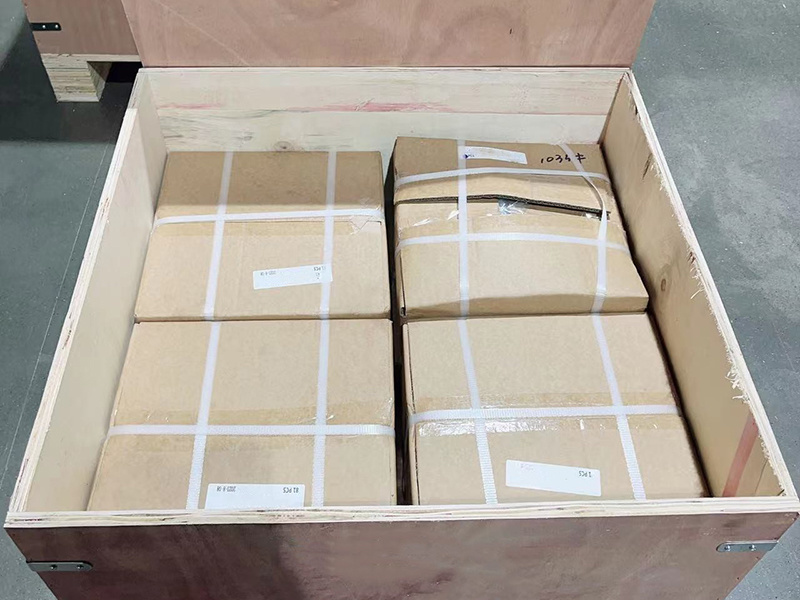

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

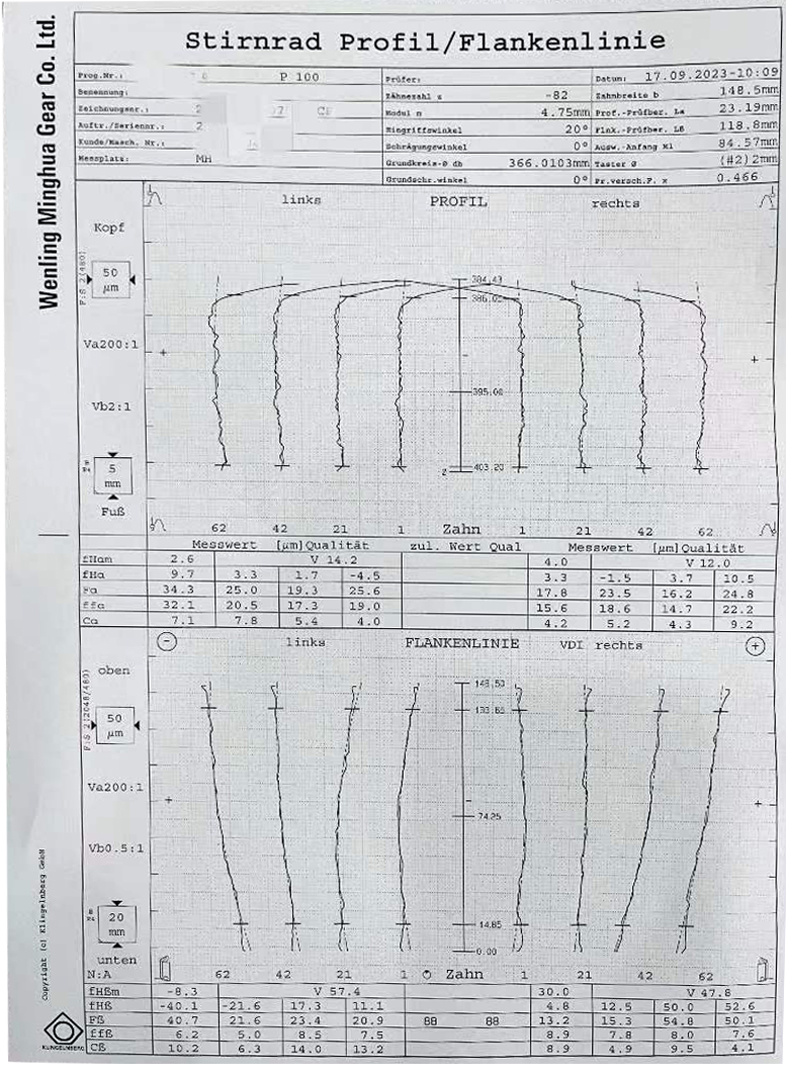

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Quality Control

Before every shipping ,we will do following testing and provide whole quality reports for these gears:

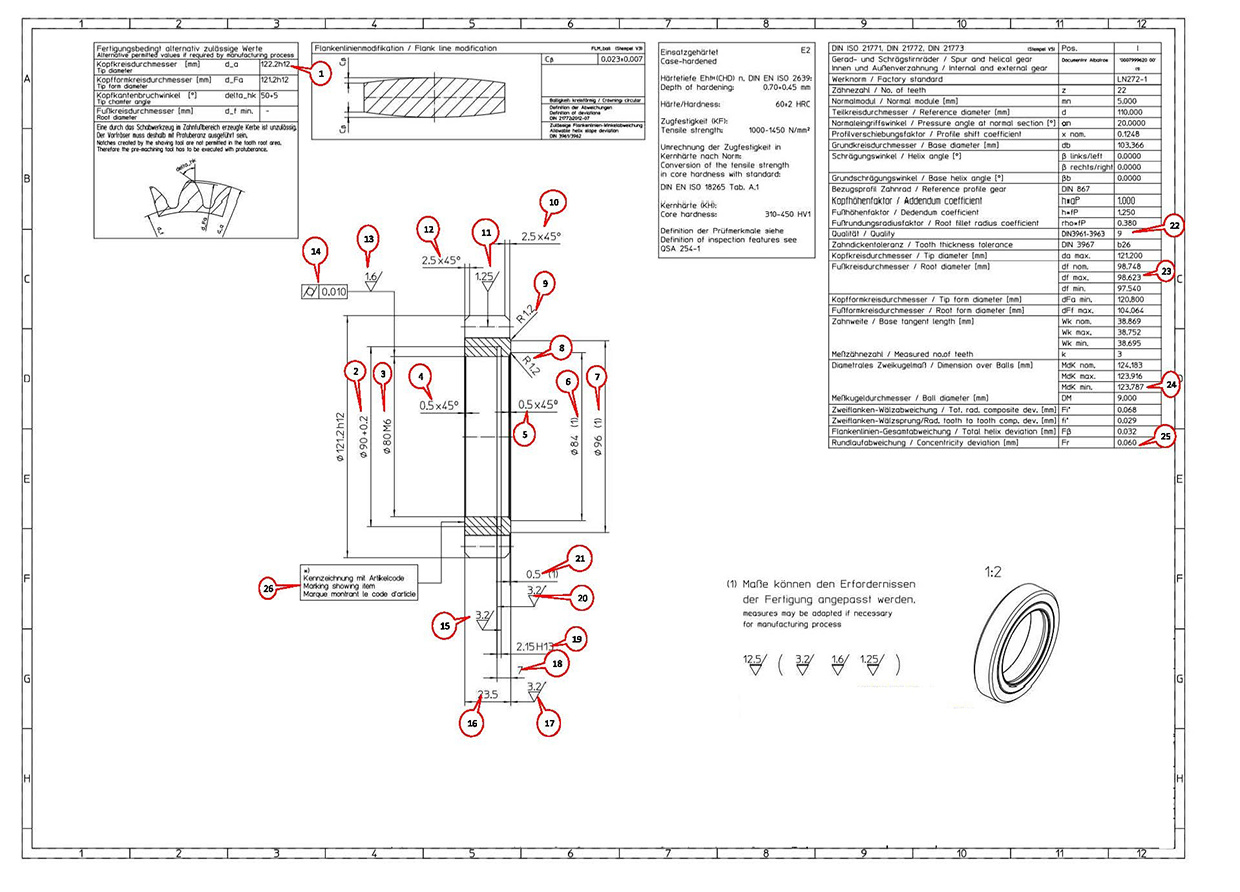

1).Bubble drawing

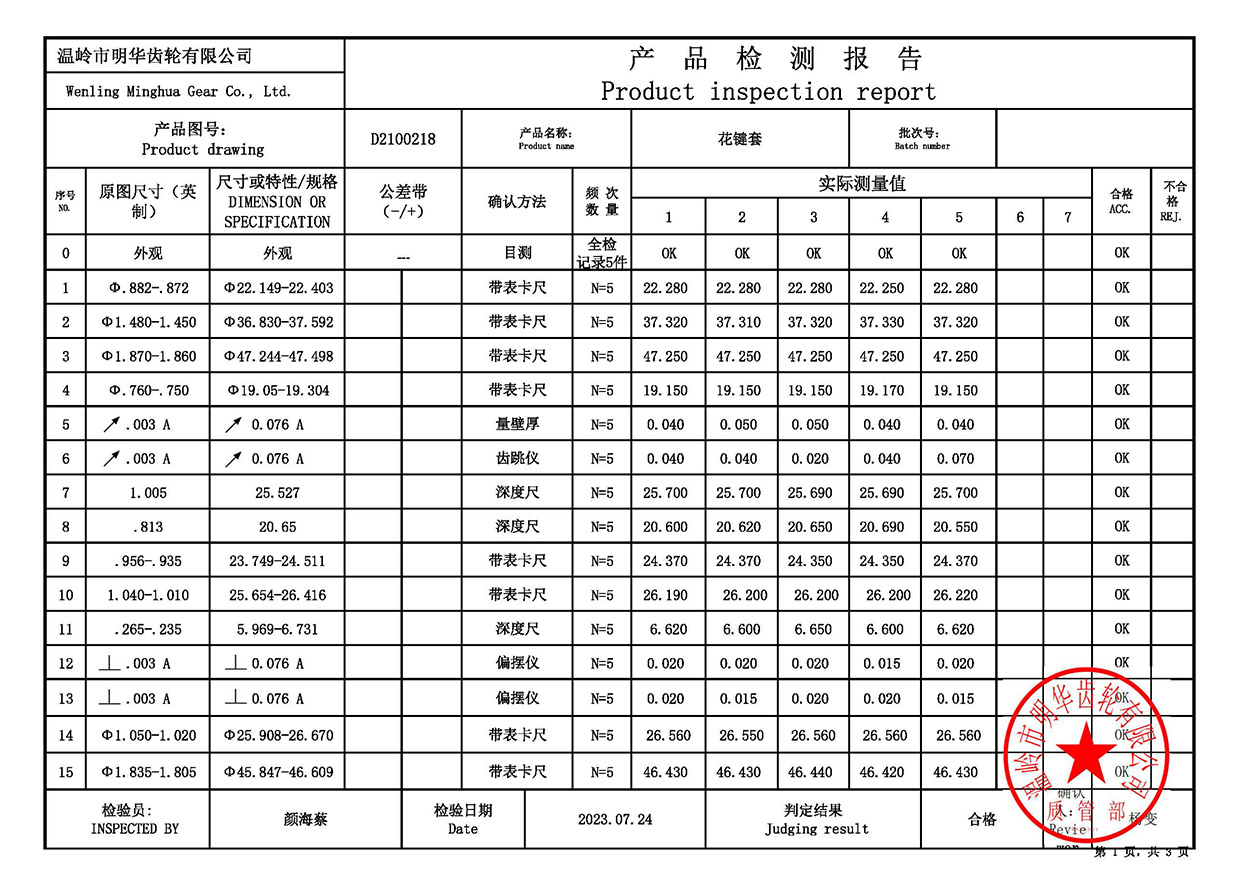

2).Dimension measurement report

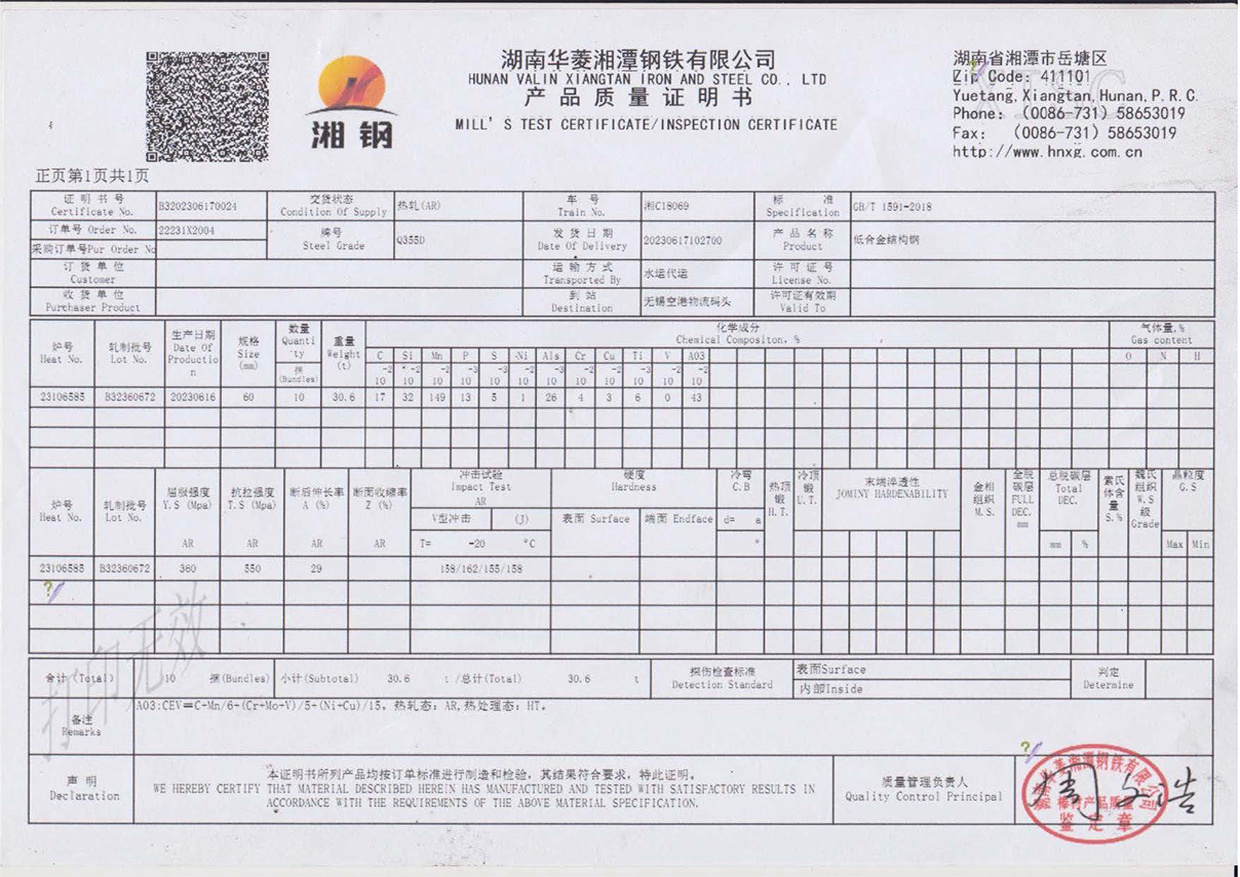

3).Material certification report

4).Heat treatment testing report

5).Accuracy measurement report

Production Strength

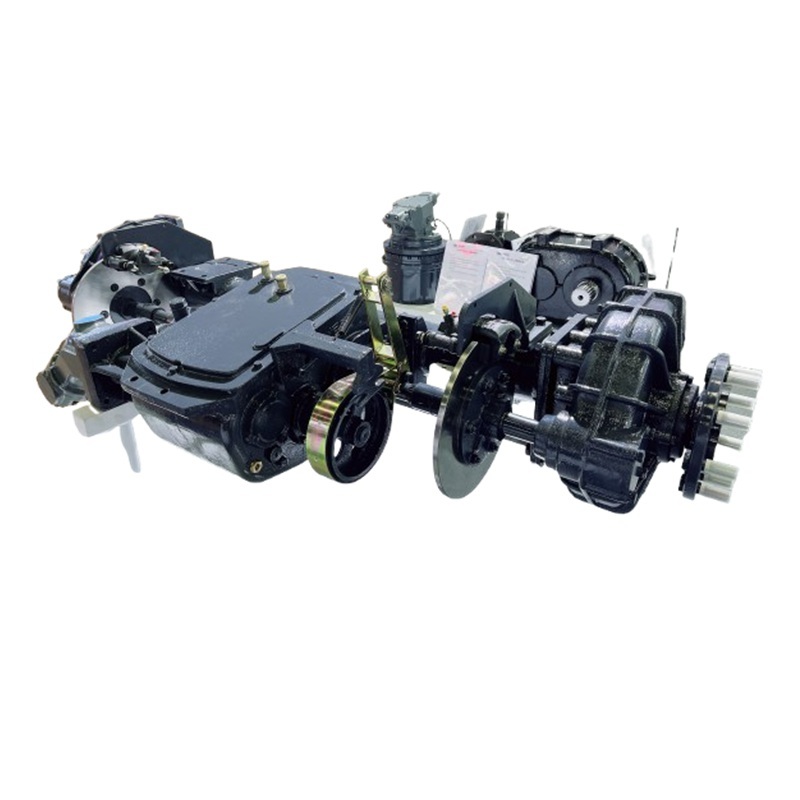

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Helical Gear for New Energy Passenger Vehicle Drive

Key words:

Heavy duty truck gear shaft

Classification:

Product Details

Helical Gear for New Energy Passenger Vehicle Drive

Helical gears are increasingly important in the drive systems of new energy passenger vehicles, such as electric vehicles (EVs) and hybrid vehicles. These gears are favored for their efficiency, quiet operation, and ability to handle high loads, which are crucial for the performance and comfort of modern vehicles.

-

Smooth and Quiet Operation:

- Helical gears have angled teeth, which engage gradually rather than all at once. This results in smoother transmission of power and significantly reduces noise and vibration. For electric vehicles, where the absence of an internal combustion engine makes gear noise more noticeable, this is a critical advantage.

-

High Load Capacity:

- The design of helical gears allows multiple teeth to be in contact simultaneously, which distributes the load more evenly across the gear. This increases the gear's load-carrying capacity, making it suitable for the high torque demands of electric vehicle drivetrains.

Minghua gear made Helical Gear for New Energy Passenger Vehicle Drive.

Precision forging, quenching&tempering, rough turning, hobbing, heat treatment, finishing turning, teeth grinding, inspection.

Gear shafts material usually use 42CrMoS4, 20MnCr5, 20CrMoH,16MnCr5, 18CrNiMo7-6 etc.

Heat treatment process available: normalizing, tempering, carburizing, quenching, high frequency, nitridation Generally, it meets the strength requirements of the material, and with excellent wear resistance.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Quality Control

Before every shipping ,we will do following testing and provide whole quality reports for these gears:

1).Bubble drawing

2).Dimension measurement report

3).Material certification report

4).Heat treatment testing report

5).Accuracy measurement report

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.