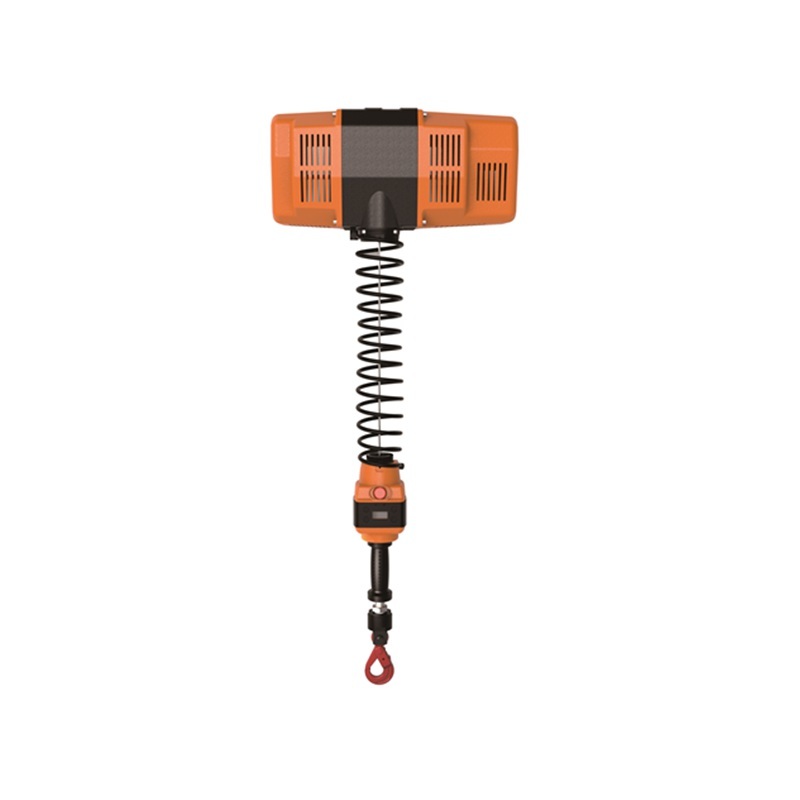

Intelligent Hoist for Industrial Factory Use

Key words:

Other products

Classification:

Product Details

Intelligent Hoist for Industrial Factory Use

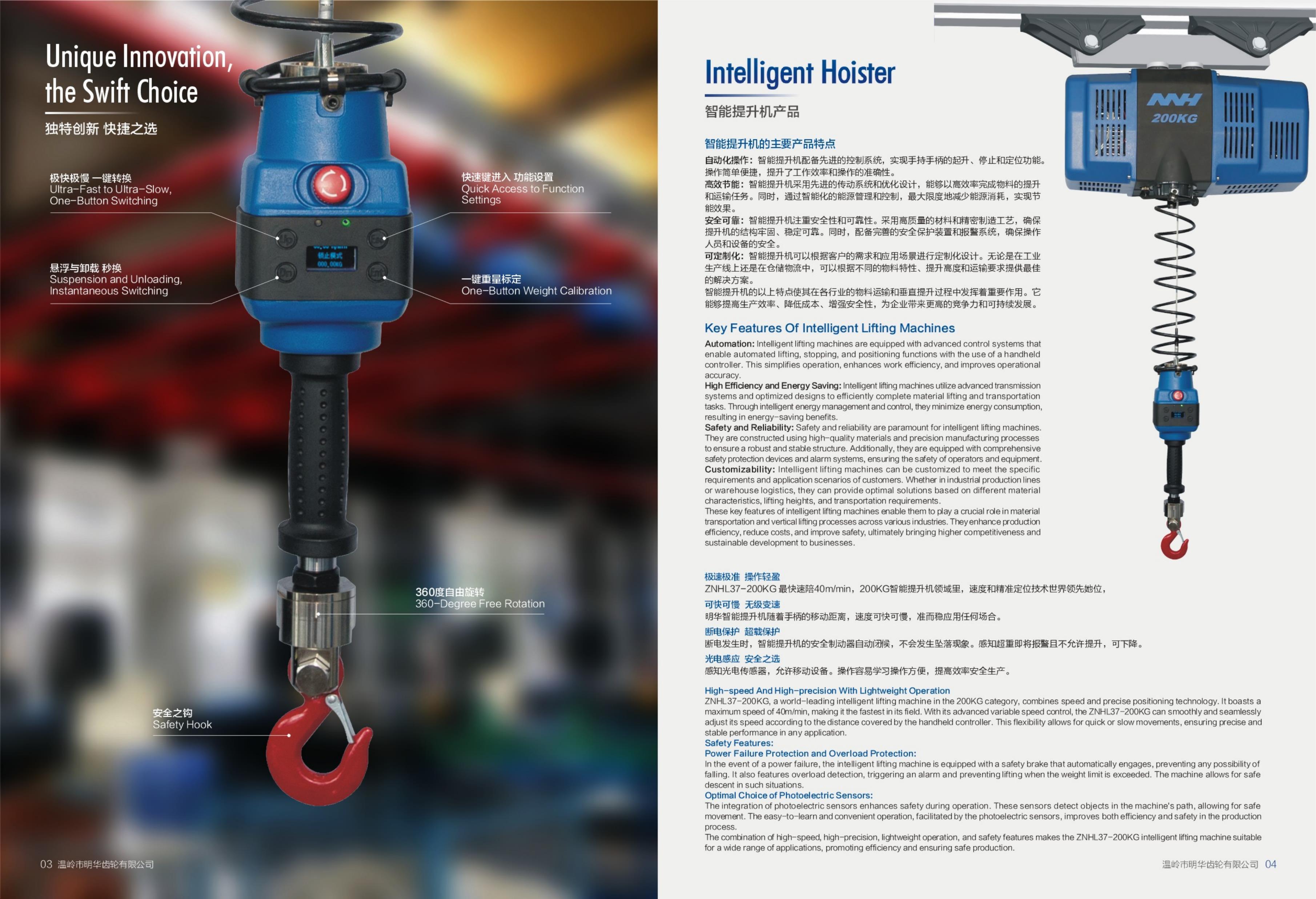

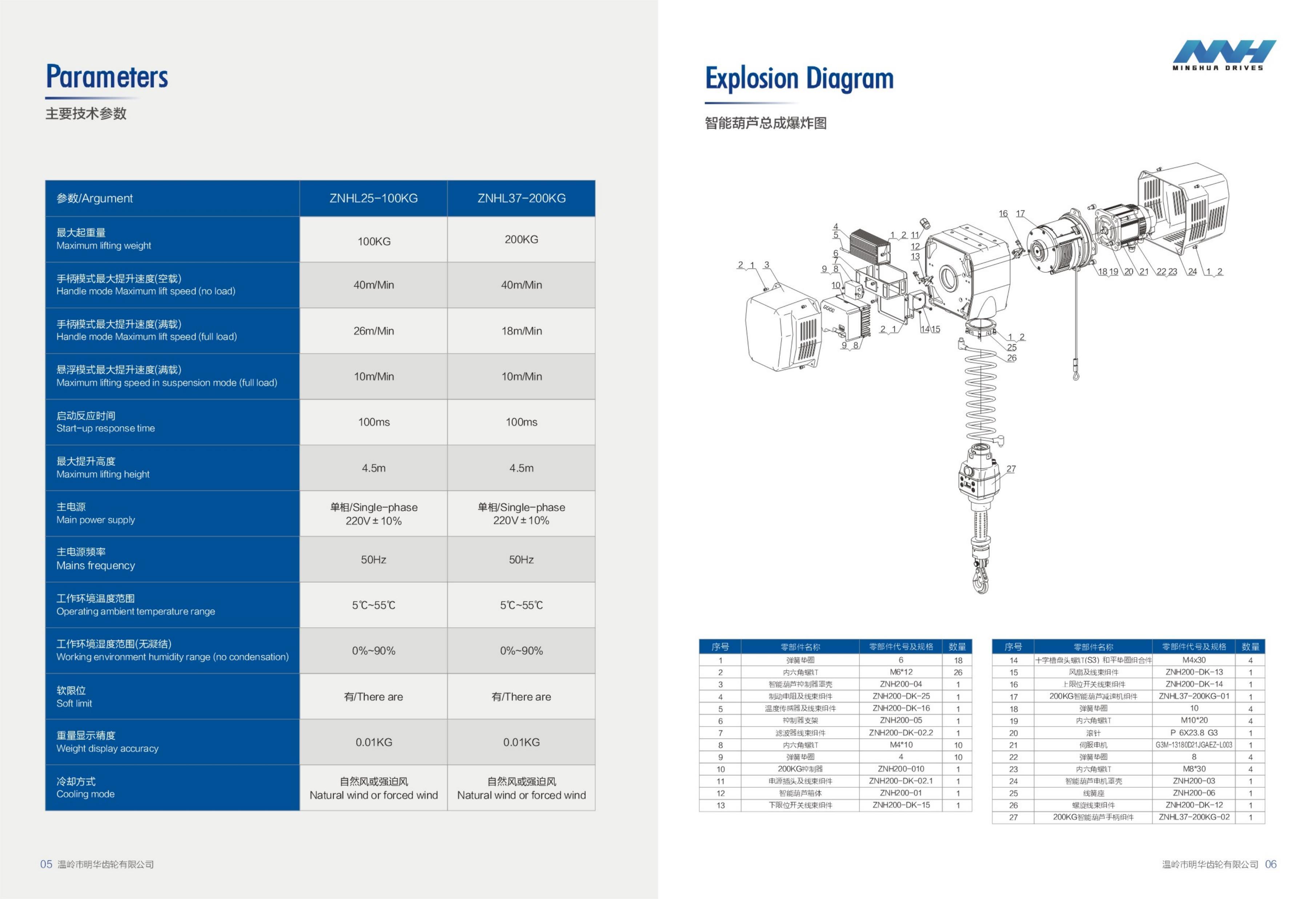

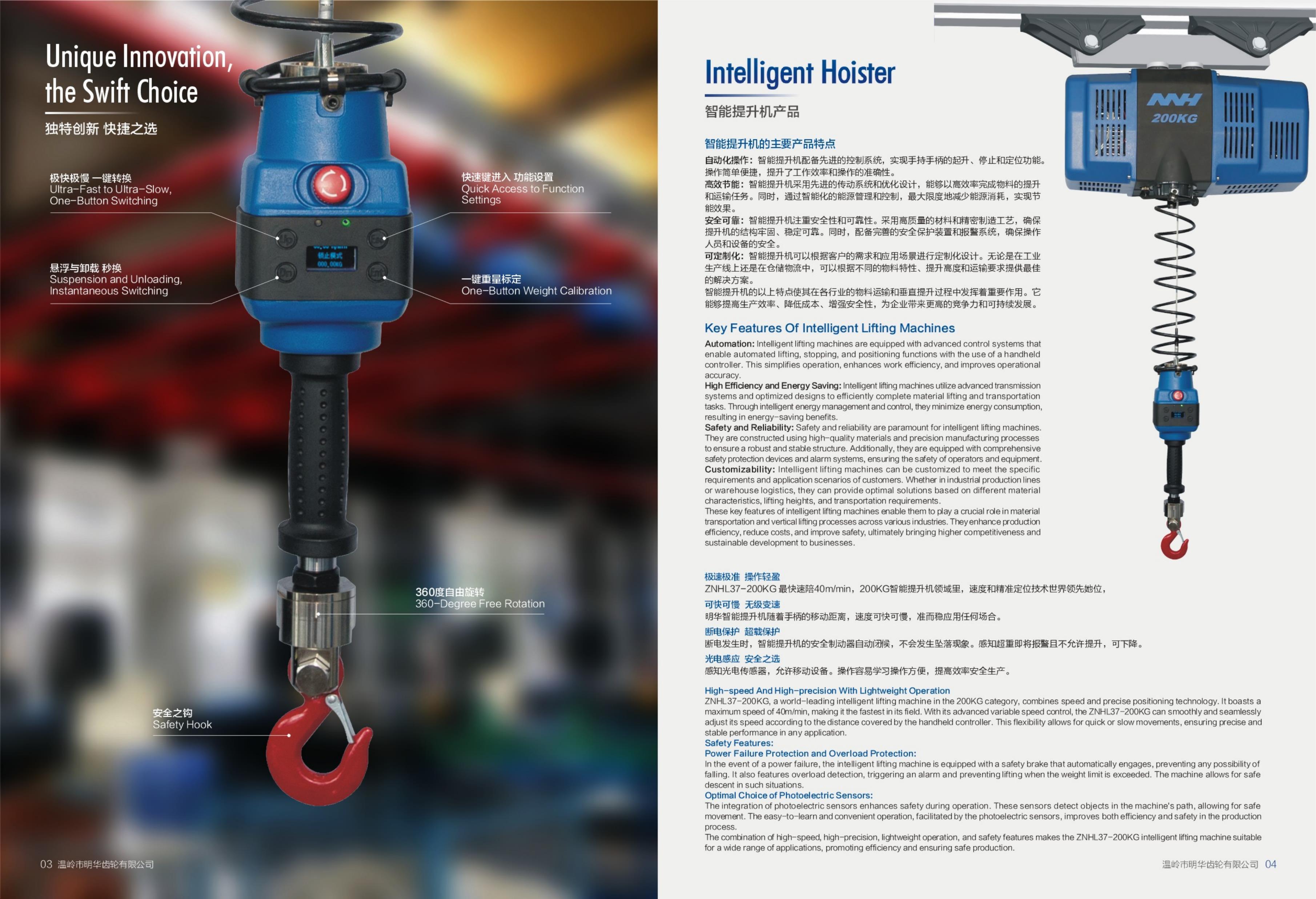

An intelligent hoist for industrial use typically combines traditional lifting capabilities with advanced features like automation, real-time monitoring, safety enhancements, and precision control. Here’s an overview of what such a system might include:

Key Features:

-

Automation & Smart Control:

- Automated Lifting: Pre-programmed lifting sequences to reduce manual intervention.

- Remote Control: Wireless control via handheld devices or central control systems.

- Integration with IoT: Connectivity with industrial IoT systems for real-time data exchange and monitoring.

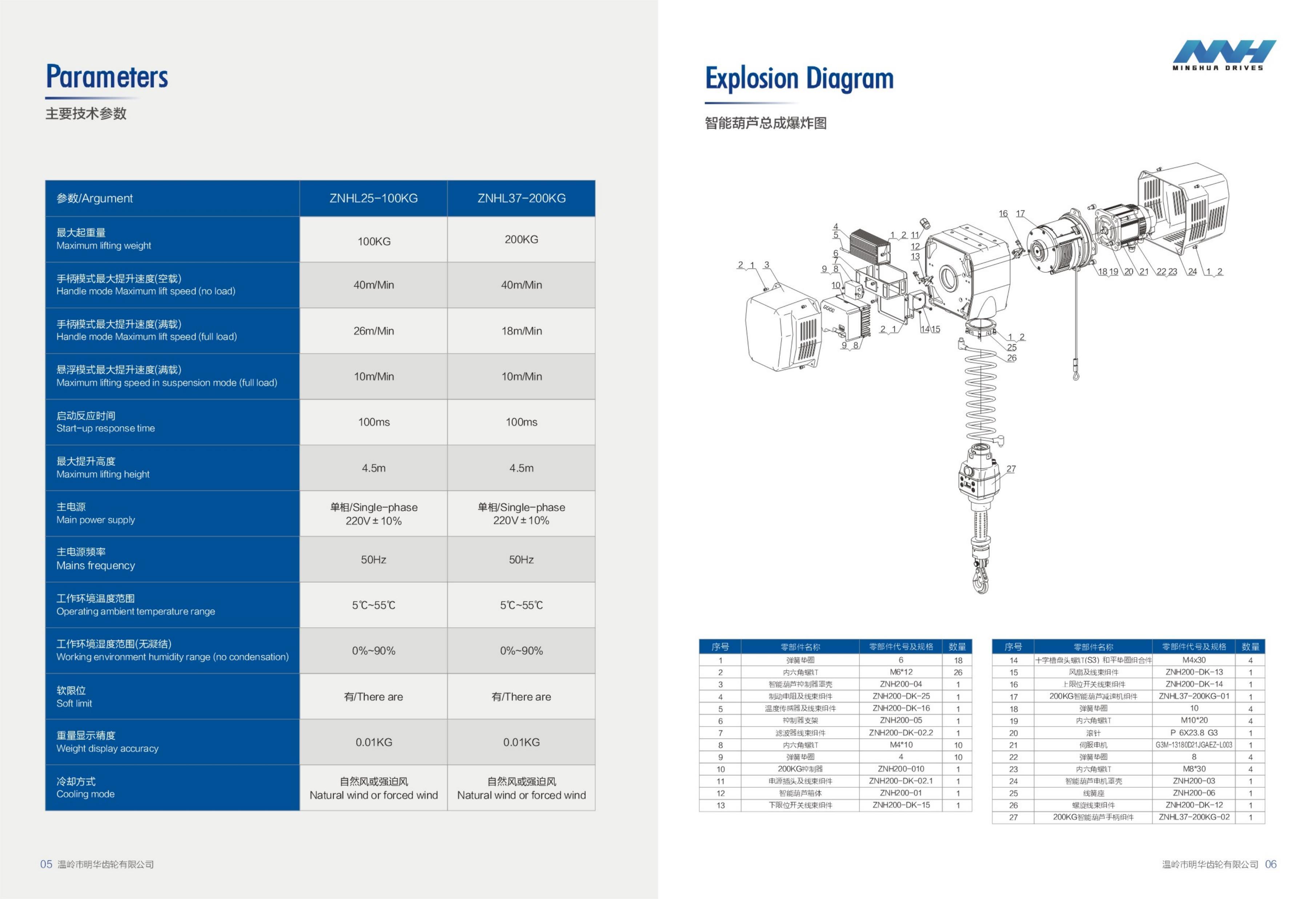

2. Precision & Efficiency:

- Positioning Accuracy: High precision in positioning and movement control, suitable for delicate or complex operations.

- Variable Speed Control: Adjustable speed settings for different types of loads and tasks.

- Energy Efficiency: Optimized power usage with regenerative braking and energy recovery systems.

Applications:

- Manufacturing: For assembly lines and material handling in factories.

- Warehousing: Efficient loading, unloading, and movement of goods.

- Construction: Lifting heavy materials on construction sites with enhanced safety.

- Energy & Utilities: Maintenance and operations in power plants, refineries, etc.

Considerations for Implementation:

- Compatibility: Ensure the hoist system is compatible with existing infrastructure.

- Customization: Tailoring features to meet specific operational needs.

- Training: Proper training for operators on new intelligent features.

- Compliance: Adherence to safety standards and regulations in your industry.

Previous

Next

Previous

Next

Intelligent Hoist for Industrial Factory Use

Key words:

Other products

Classification:

Product Details

Intelligent Hoist for Industrial Factory Use

An intelligent hoist for industrial use typically combines traditional lifting capabilities with advanced features like automation, real-time monitoring, safety enhancements, and precision control. Here’s an overview of what such a system might include:

Key Features:

-

Automation & Smart Control:

- Automated Lifting: Pre-programmed lifting sequences to reduce manual intervention.

- Remote Control: Wireless control via handheld devices or central control systems.

- Integration with IoT: Connectivity with industrial IoT systems for real-time data exchange and monitoring.

2. Precision & Efficiency:

- Positioning Accuracy: High precision in positioning and movement control, suitable for delicate or complex operations.

- Variable Speed Control: Adjustable speed settings for different types of loads and tasks.

- Energy Efficiency: Optimized power usage with regenerative braking and energy recovery systems.

Applications:

- Manufacturing: For assembly lines and material handling in factories.

- Warehousing: Efficient loading, unloading, and movement of goods.

- Construction: Lifting heavy materials on construction sites with enhanced safety.

- Energy & Utilities: Maintenance and operations in power plants, refineries, etc.

Considerations for Implementation:

- Compatibility: Ensure the hoist system is compatible with existing infrastructure.

- Customization: Tailoring features to meet specific operational needs.

- Training: Proper training for operators on new intelligent features.

- Compliance: Adherence to safety standards and regulations in your industry.

Previous

Next

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.