Center Selical Gear For Industrial Robot Arm

Key words:

Gear、shaft

Classification:

Product Details

Center Selical Gear For Industrial Robot Arm

Spur gears are another common type of gear used in industrial robot arms. While they differ from helical gears in terms of tooth orientation and performance characteristics, they offer unique advantages in certain applications.

Advantages of Spur Gears for Robot Arms:

-

Simplicity and Cost-Effectiveness:

- Spur gears are straightforward in design and easier to manufacture compared to helical gears. This makes them more cost-effective, especially for applications where budget constraints are a concern.

-

High Efficiency:

- Spur gears have high transmission efficiency because the teeth engage and disengage simultaneously, leading to minimal energy loss. This is beneficial in applications where maximum power transfer is needed.

-

No Axial Thrust:

- Unlike helical gears, spur gears generate no axial thrust, which simplifies the bearing and support design, reducing the complexity of the robot arm's mechanical structure.

-

Precision in Low-Speed Applications:

- Spur gears can provide precise movement in applications where speed is relatively low and high precision is required, making them suitable for certain robotic joints or actuators.

Precision forging, quenching&tempering, rough turning, hobbing, heat treatment, finishing turning, teeth grinding, inspection.

Applications in Robot Arms:

Spur gears are often used in robot arms where simplicity and cost-effectiveness are priorities, and where the operating environment is relatively low in speed and load. They are commonly found in:

- Low-torque actuators: Where the simplicity of spur gears is an advantage.

- Gear trains: Spur gears are used in gear trains to transfer motion between shafts at different angles or to increase/decrease speed and torque.

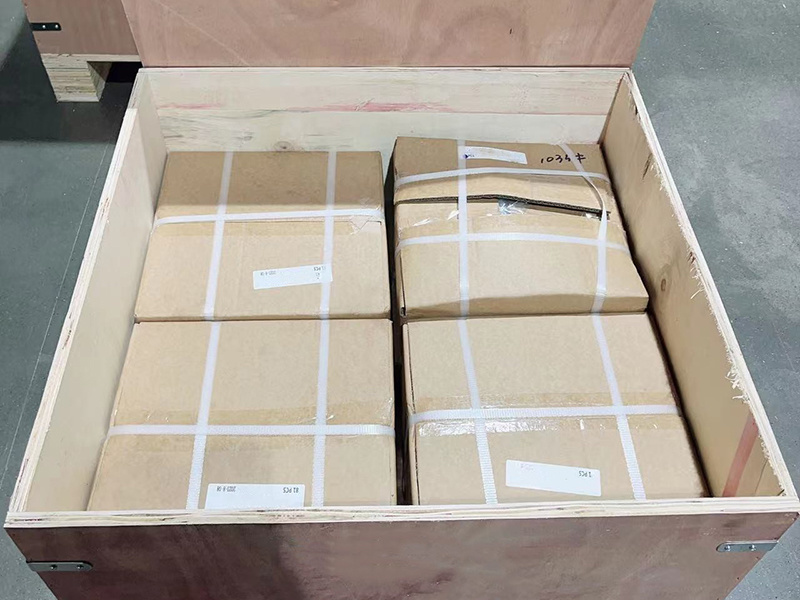

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

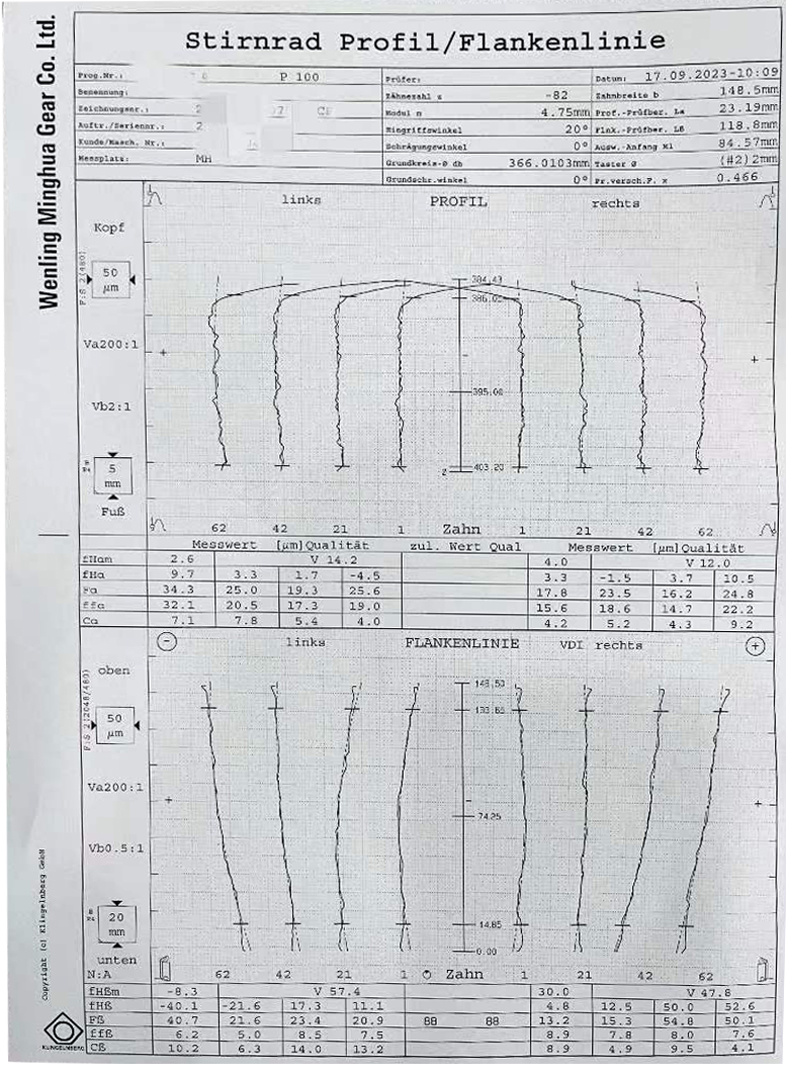

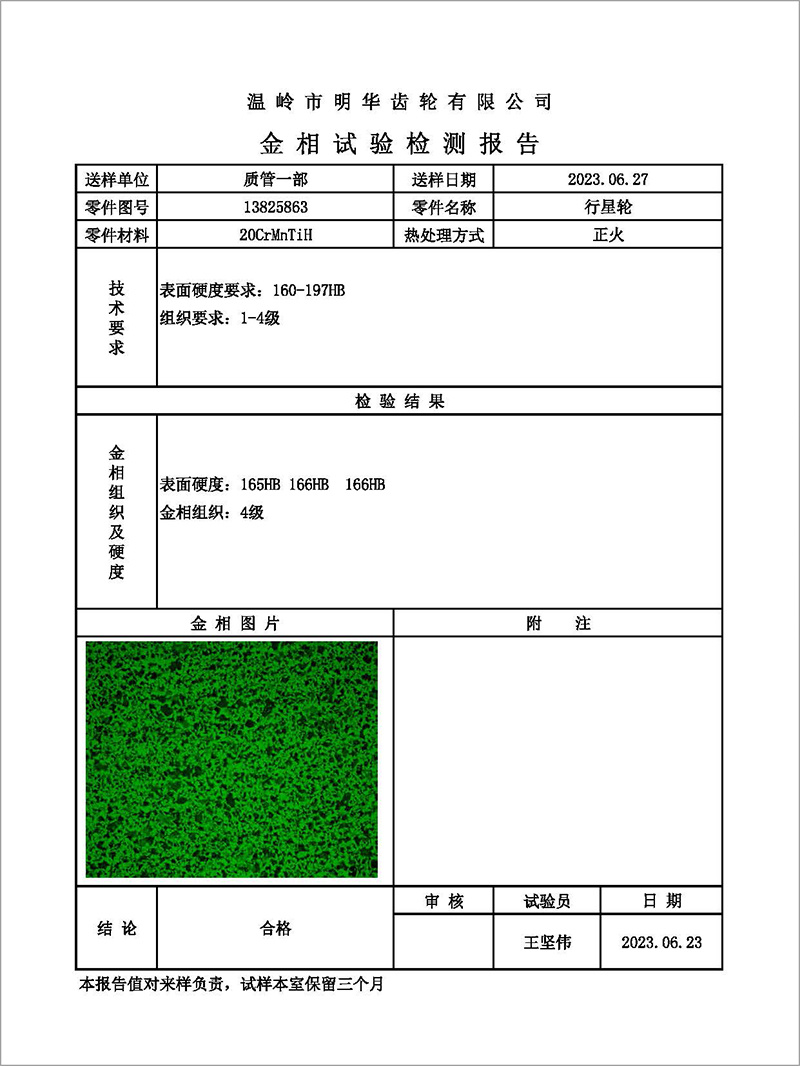

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Quality Control

Before every shipping ,we will do following testing and provide whole quality reports for these gears:

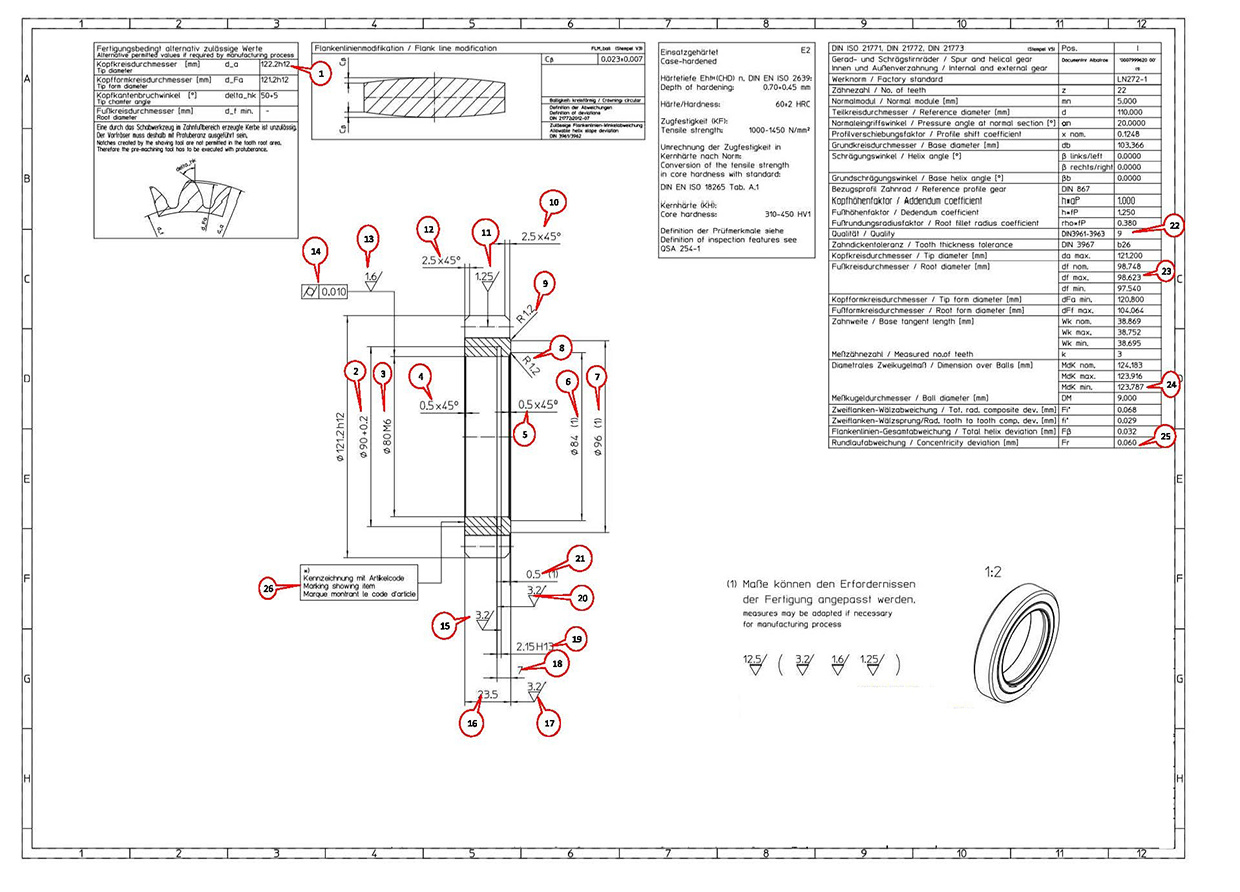

1).Bubble drawing

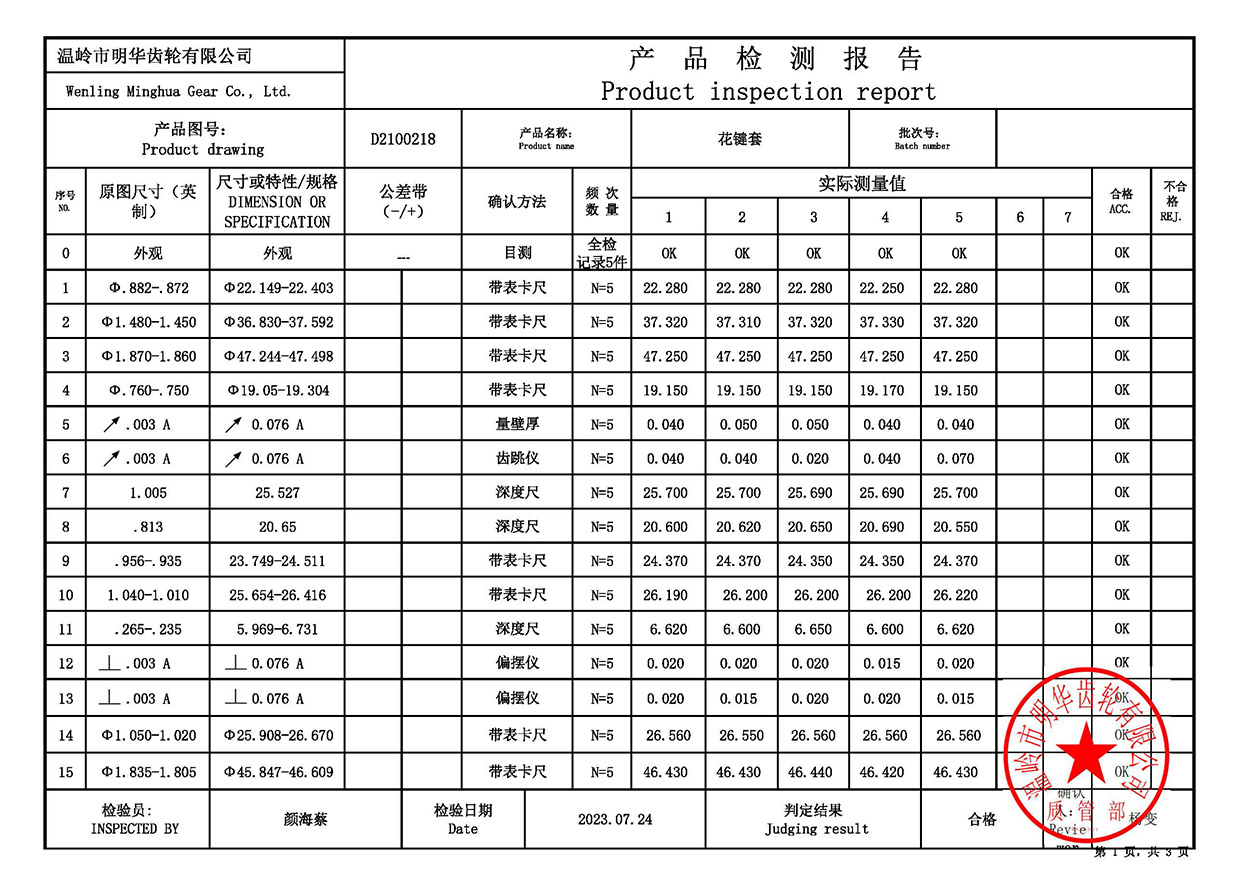

2).Dimension measurement report

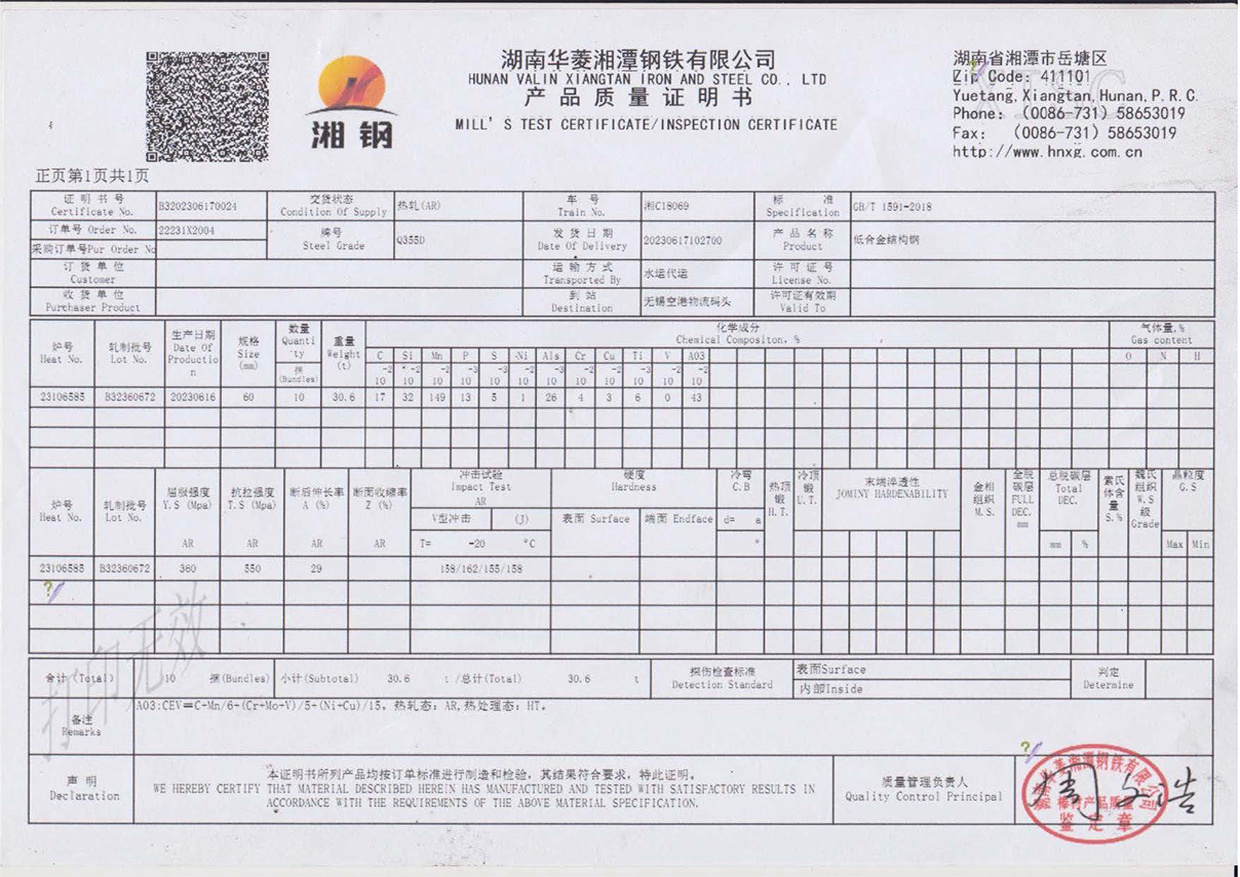

3).Material certification report

4).Heat treatment testing report

5).Accuracy measurement report

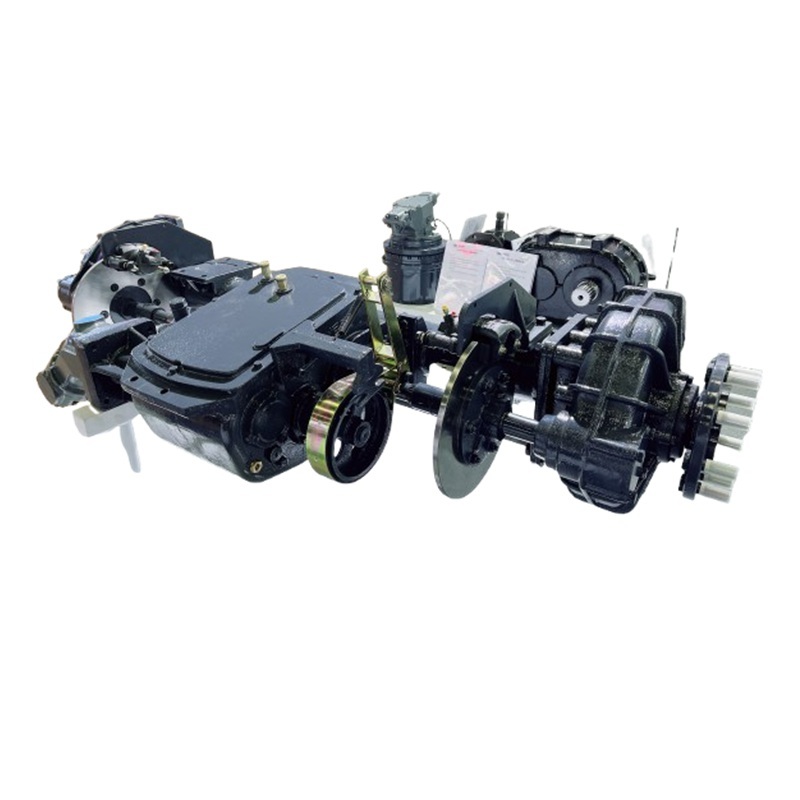

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Center Selical Gear For Industrial Robot Arm

Key words:

Gear、shaft

Classification:

Product Details

Center Selical Gear For Industrial Robot Arm

Spur gears are another common type of gear used in industrial robot arms. While they differ from helical gears in terms of tooth orientation and performance characteristics, they offer unique advantages in certain applications.

Advantages of Spur Gears for Robot Arms:

-

Simplicity and Cost-Effectiveness:

- Spur gears are straightforward in design and easier to manufacture compared to helical gears. This makes them more cost-effective, especially for applications where budget constraints are a concern.

-

High Efficiency:

- Spur gears have high transmission efficiency because the teeth engage and disengage simultaneously, leading to minimal energy loss. This is beneficial in applications where maximum power transfer is needed.

-

No Axial Thrust:

- Unlike helical gears, spur gears generate no axial thrust, which simplifies the bearing and support design, reducing the complexity of the robot arm's mechanical structure.

-

Precision in Low-Speed Applications:

- Spur gears can provide precise movement in applications where speed is relatively low and high precision is required, making them suitable for certain robotic joints or actuators.

Precision forging, quenching&tempering, rough turning, hobbing, heat treatment, finishing turning, teeth grinding, inspection.

Applications in Robot Arms:

Spur gears are often used in robot arms where simplicity and cost-effectiveness are priorities, and where the operating environment is relatively low in speed and load. They are commonly found in:

- Low-torque actuators: Where the simplicity of spur gears is an advantage.

- Gear trains: Spur gears are used in gear trains to transfer motion between shafts at different angles or to increase/decrease speed and torque.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Quality Control

Before every shipping ,we will do following testing and provide whole quality reports for these gears:

1).Bubble drawing

2).Dimension measurement report

3).Material certification report

4).Heat treatment testing report

5).Accuracy measurement report

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.