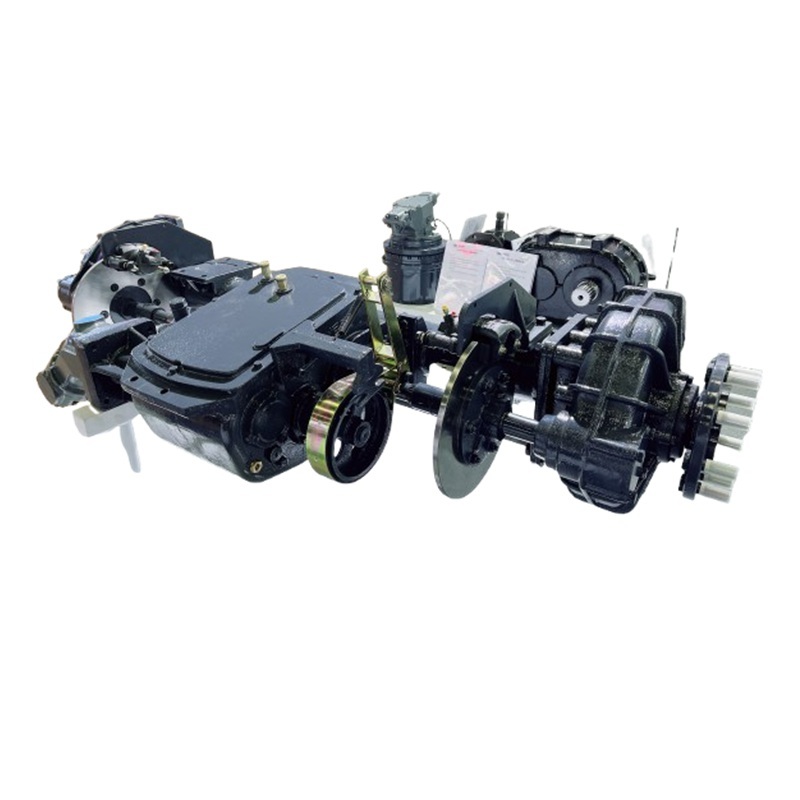

Hydraulic Gear Reducer Manufacture Planetary Gear Reducer For Rotary Drilling Rig Use

Key words:

Planetary reducer

Classification:

Product Details

Features introduction:

The drive design is based on many years of practical application experience.

The output torque rates are tailored to the application requirements of an excavator travel drive.

For other application higher output torques than those specified may be permissible for the relevant gearbox.

Application-related consultation is available to all users as early as in the project stage.

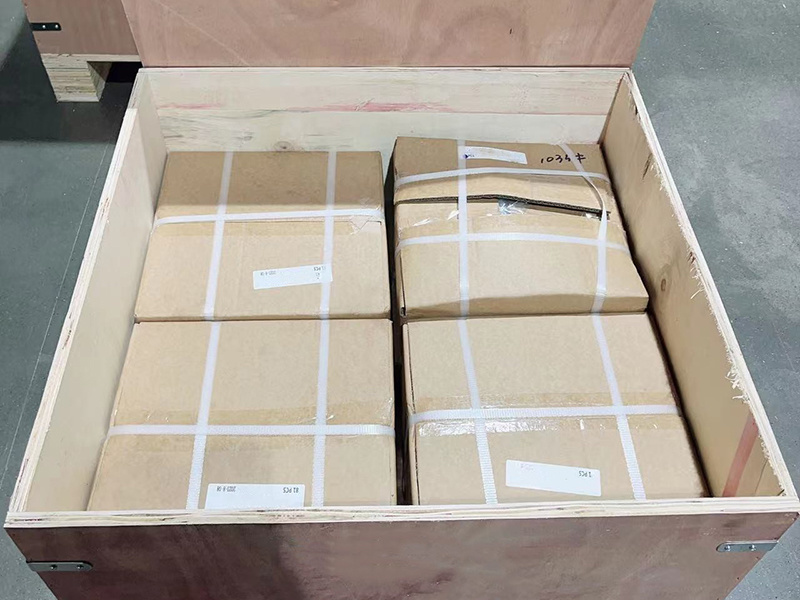

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

Hydraulic Gear Reducer Manufacture Planetary Gear Reducer For Rotary Drilling Rig Use

Key words:

Planetary reducer

Classification:

Product Details

Features introduction:

The drive design is based on many years of practical application experience.

The output torque rates are tailored to the application requirements of an excavator travel drive.

For other application higher output torques than those specified may be permissible for the relevant gearbox.

Application-related consultation is available to all users as early as in the project stage.

Packaging

With inside anti-rust bag then packed in durable plywood crate box.

Testing Equipment

Full process inspection and testing.

Include gear precision grade testing, CMM inspection, Metallographic analysis and testing,torque testing…etc.

Production Strength

Full process from forging blank to finished gearbox.

Include forging gear, foundry housing, gear profile process (include hobbing, shaping, shaving, broaching…etc.) assembly, painting, packing.

Previous

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: 8613905863798

Copyright©2023 Wenling Minghua Gear Co., Ltd.